Laser Rust Removal: The Ultimate Guide to Efficient and Eco-Friendly Cleaning

I. Introduction

A. The Growing Demand for Efficient Rust Removal Methods

Rust, also known as iron oxide, is a common problem that affects various industries, including automotive, aerospace, and manufacturing. The presence of rust not only diminishes the aesthetics of metal surfaces but also leads to structural integrity issues, reduced performance, and decreased lifespan of machinery and equipment. As a result, there is a growing demand for efficient, effective, and environmentally friendly rust removal methods.

Traditional methods, such as sandblasting, chemical treatments, and manual scraping, can be time-consuming, labor-intensive, and damaging to the surface of the material. Additionally, these methods often involve the use of harmful chemicals, generating waste that poses risks to both human health and the environment.

B. The Emergence of Laser Rust Removal Technology

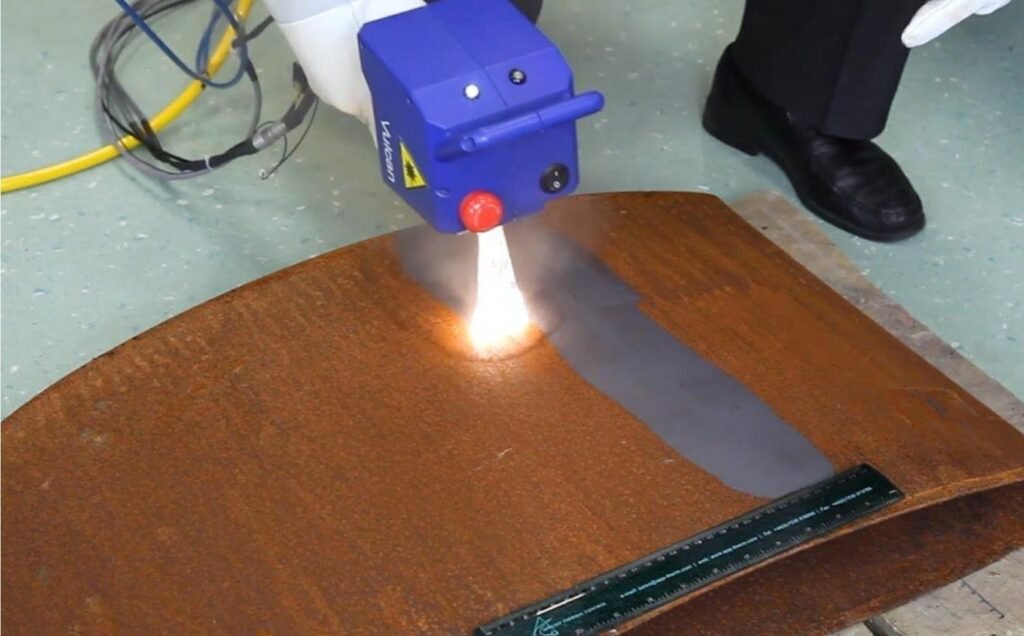

In response to the need for better rust removal solutions, laser rust removal technology has emerged as a revolutionary alternative. This innovative method harnesses the power of laser beams to efficiently remove rust, paint, and other contaminants from metal surfaces without causing damage or generating harmful waste. It offers numerous advantages over traditional techniques, such as precision, speed, and eco-friendliness.

In this article, we will explore the science behind laser rust removal, the various types of laser cleaning machines available, and how to choose the right system for your specific needs. Read on to discover the benefits of laser rust removal technology and how it is changing the way we clean and maintain our equipment and infrastructure.

II. How Does Laser Rust Removal Work?

A. The Science Behind Laser Cleaning

Laser rust removal works on the principle of laser ablation, a process that involves the use of a high-energy laser beam to remove rust, paint, and other contaminants from a metal surface. The laser beam is focused on the rusted area, and its energy is absorbed by the rust particles, causing them to heat up and vaporize. This process leaves behind a clean, rust-free surface without causing damage to the underlying material.

The success of laser rust removal depends on the laser’s wavelength, pulse duration, and power. These factors determine the efficiency and precision of the cleaning process, ensuring that only the rust particles are removed without affecting the base material.

B. Laser Cleaning Machine Components

A typical laser rust removal machine consists of the following components:

- Laser Source: This generates the laser beam used for rust removal. Common types of laser sources include solid-state lasers, such as fiber lasers, and gas lasers, such as CO2 lasers.

- Optical System: This includes lenses and mirrors that direct and focus the laser beam onto the rusted surface.

- Scanning System: This consists of galvanometers that control the movement of the laser beam across the surface, allowing for precise and rapid cleaning.

- Control Unit: This is the brain of the laser cleaning machine, responsible for adjusting the laser’s parameters, such as power, pulse duration, and scanning speed, to achieve optimal cleaning results.

- Cooling System: This keeps the laser source and other components at an appropriate temperature to prevent overheating and maintain optimal performance.

C. Advantages of Laser Rust Removal

Laser rust removal offers numerous benefits over traditional rust removal methods, making it an attractive option for various industries. Some of these advantages include:

- Precision: Laser cleaning enables precise removal of rust and other contaminants without affecting the underlying material, preserving its integrity and preventing damage.

- Speed: The process is significantly faster than traditional methods like sandblasting or chemical treatments, saving time and labor costs.

- Environmentally Friendly: Laser rust removal generates minimal waste and does not require the use of harmful chemicals, making it an eco-friendly alternative.

- Non-Contact: The laser cleaning process does not involve physical contact with the surface, reducing the risk of damage and wear.

- Versatility: Laser rust removal can be used on various materials, including metals, plastics, and ceramics, making it suitable for a wide range of applications.

- Low Maintenance: Laser cleaning machines require minimal maintenance compared to traditional cleaning equipment, reducing long-term operational costs.

III. Types of Laser Rust Removal Machines

A. Handheld Laser Cleaner: [handheld laser cleaner price]

Handheld laser cleaners are portable and lightweight, making them ideal for smaller-scale cleaning tasks, spot cleaning, and hard-to-reach areas. These devices typically have lower power outputs, ranging from 20W to 200W, but still offer efficient and precise rust removal. The handheld laser cleaner price varies depending on the power output, features, and brand, with costs ranging from $5,000 to $25,000.

B. Industrial Laser Cleaning Machine: [industrial laser cleaning machine]

Industrial laser cleaning machines are designed for heavy-duty, large-scale rust removal tasks in industries such as automotive, aerospace, and manufacturing. These machines are equipped with higher power outputs, typically between 200W and 1000W, and often include advanced features such as automated scanning systems, programmable control units, and integrated cooling systems. Industrial laser cleaning machines are more expensive than handheld units, with prices ranging from $30,000 to $200,000, depending on the power output, features, and brand.

C. Fiber Laser Rust Removal Systems: [fiber laser rust removal]

Fiber laser rust removal systems utilize solid-state fiber lasers, which offer several advantages over other types of lasers, such as CO2 or Nd:YAG lasers. Fiber lasers provide higher peak power, shorter pulse durations, and greater efficiency, resulting in faster, more precise rust removal. These systems are available in both handheld and industrial configurations and are well-suited for a variety of applications, including metal surface cleaning, paint removal, and mold cleaning. Fiber laser rust removal systems typically have a higher price point than other types of laser cleaning machines due to their advanced technology, with costs ranging from $20,000 to $250,000.

IV. Popular Laser Cleaning Systems and Their Applications

A. 1000W Rust Cleaning Laser: [1000w rust cleaning laser]

The 1000W rust cleaning laser systems are high-powered industrial machines suitable for heavy-duty rust removal and large-scale cleaning tasks. With their high power output, these systems offer fast and efficient cleaning of rust, paint, and other contaminants from metal surfaces. Typical applications for 1000W rust cleaning lasers include:

- Automotive and aerospace industries: Removing rust, paint, and other surface contaminants from large vehicle components, aircraft structures, and engines.

- Heavy machinery and equipment: Cleaning rust and corrosion from large industrial equipment and machinery parts.

- Shipbuilding and marine maintenance: Removing rust, paint, and marine growth from ship hulls, propellers, and other marine structures.

- Infrastructure maintenance: Cleaning rust and other contaminants from bridges, pipelines, and other large-scale infrastructure components.

B. 100W Rust Cleaning Laser: [100w rust cleaning laser price]

The 100W rust cleaning laser systems offer a balance between power and portability, making them versatile tools for various cleaning tasks. With a lower power output than their 1000W counterparts, these systems are more affordable while still providing efficient rust removal. Typical applications for 100W rust cleaning lasers include:

- Automotive and aerospace industries: Removing rust and paint from smaller vehicle components, aircraft parts, and other metal surfaces.

- Tool and die manufacturing: Cleaning rust, scale, and other contaminants from molds, dies, and precision tooling.

- Restoration and conservation: Removing rust, paint, and other surface contaminants from historical artifacts, sculptures, and architectural elements without damaging the underlying material.

- General maintenance: Cleaning rust and other contaminants from various metal surfaces in industrial, commercial, and residential settings.

C. 20W Laser Rust Removal: [20w laser rust removal]

The 20W laser rust removal systems are compact and lightweight, making them ideal for small-scale cleaning tasks and spot cleaning. These systems are suitable for applications where high precision and minimal surface damage are critical, such as cleaning delicate and intricate parts. Typical applications for 20W laser rust removal systems include:

- Electronics and semiconductor manufacturing: Removing rust, oxidation, and other contaminants from electronic components, circuit boards, and semiconductor wafers.

- Jewelry and watchmaking: Cleaning rust, tarnish, and other surface contaminants from precious metals, gemstones, and intricate watch components.

- Dental and medical equipment: Removing rust and other contaminants from dental tools, surgical instruments, and other medical equipment without causing damage.

- Art restoration: Cleaning rust, paint, and other surface contaminants from delicate artifacts, paintings, and sculptures while preserving the original material.

V. Laser Cleaning System Accessories and Tools

A. Laser Blaster Cleaner: [laser blaster cleaner]

Laser blaster cleaners are specialized attachments or accessories designed to enhance the cleaning capabilities of laser systems. These devices typically focus the laser beam or direct it in a specific pattern, improving the efficiency and precision of the rust removal process. Laser blaster cleaners are often used in applications where high precision or rapid cleaning is required, such as cleaning large surfaces or removing heavy rust deposits.

B. Laser Derusting Tool: [laser derusting tool]

Laser derusting tools are handheld devices or attachments designed specifically for the removal of rust from metal surfaces. These tools usually feature a compact design and lower power output, making them suitable for small-scale cleaning tasks and hard-to-reach areas. Laser derusting tools are ideal for use in industries such as automotive, aerospace, and restoration, where precise rust removal is essential for maintaining the functionality and appearance of components.

C. Laser Cleaner for Metal: [laser cleaner for metal]

Laser cleaners for metal are versatile laser cleaning systems designed specifically for use on various metal surfaces, including steel, aluminum, brass, and copper. These machines typically offer a range of power outputs and features to cater to different cleaning requirements, such as rust removal, paint stripping, and surface preparation. Laser cleaners for metal are commonly used in industries such as automotive, aerospace, manufacturing, and restoration, where efficient and precise cleaning is critical for maintaining the performance, durability, and aesthetics of metal components and structures.

VI. Choosing the Right Laser Cleaning Machine for Your Needs

A. Factors to consider

When selecting a laser cleaning machine, it’s essential to consider several factors to ensure you choose the best system for your specific needs. Some of the factors to consider include:

- Power output: Determine the appropriate power output based on the type and extent of rust removal required. Higher power outputs are more suitable for heavy-duty cleaning tasks, while lower power outputs are ideal for delicate and intricate cleaning.

- Portability: Consider whether you need a handheld, portable system for small-scale tasks or an industrial, stationary machine for large-scale cleaning.

- Laser type: Evaluate the advantages and disadvantages of different types of lasers, such as fiber lasers, CO2 lasers, and Nd:YAG lasers, to determine the most suitable option for your specific application.

- Budget: Determine your budget and weigh the costs against the features and performance of various laser cleaning machines to find the best value.

- Application: Assess the specific requirements of your industry and application to identify the most suitable laser cleaning system.

B. Recommended laser cleaning machines

For a comprehensive selection of high-quality laser cleaning machines, visit [https://lasersourcing.com/laser-cleaning-machine/]. This website offers a wide range of laser cleaning systems, from handheld devices to industrial machines, catering to various industries and applications. Explore their offerings to find the perfect laser cleaning solution for your rust removal needs.

VII. Conclusion

A. The future of laser rust removal technology

As industries continue to seek efficient, eco-friendly, and precise cleaning solutions, the demand for laser rust removal technology will likely grow. Advancements in laser technology, such as higher power outputs, improved efficiency, and more compact designs, will further enhance the capabilities of laser cleaning systems, making them even more attractive alternatives to traditional rust removal methods.

B. Embracing eco-friendly and efficient cleaning methods

Laser rust removal has proven to be an effective, environmentally friendly, and precise method for cleaning various metal surfaces. By adopting this technology, industries can significantly reduce their environmental impact, improve the longevity and performance of their equipment, and enhance the overall quality of their products. By choosing the right laser cleaning machine for your specific needs, you can enjoy the numerous benefits of this innovative rust removal solution.