Laser Cleaning Machine

Laser cleaning machines are advanced tools that use laser technology to clean and remove rust, scale, and other contaminants from a variety of surfaces. They come in different forms including handheld laser cleaners, laser rust removal machines, and laser descaling machines. These machines use high-powered lasers to generate short pulses of energy that break down the bonds between the contaminant and the surface, effectively removing it without causing damage to the underlying material. They are widely used in various industries such as aerospace, automotive, and marine for efficient and effective cleaning.

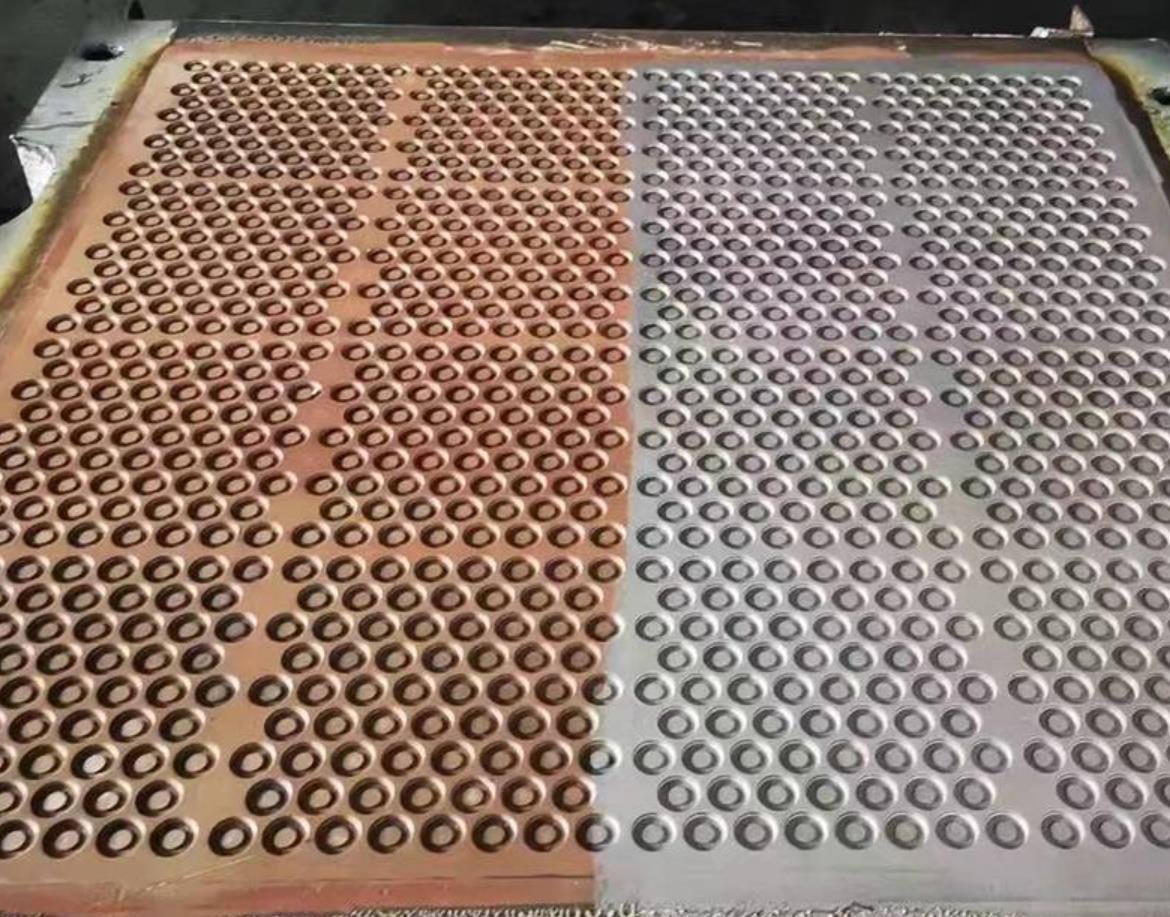

fiber laser cleaner rust removal

laser metal cleaning machine

fiber laser cleaner rust removal

100w laser cleaning machine

Still not finding what you're looking for? Contact our consultants for more available products.

Full Laser Cleaning Machine Solutions Supplier

The laser cleaning machine offers several benefits to our clients, including cost savings, portability, efficiency, high quality, power, and versatility. With our comprehensive product portfolio and fast delivery, we strive to meet our clients’ demands and help them increase their productivity while reducing stress. By choosing our laser derusting machine, our clients can enjoy the benefits of a reliable and high-quality laser rust remover at an affordable price. With our fiber laser cleaner, 1000w laser cleaner, and laser rust remover for sale, we offer a range of solutions to meet the different needs of our clients.

Cost-Effective

Laser cleaning machines are much more cost-effective in the long run compared to traditional cleaning methods. They save on labor costs, chemical costs, and maintenance costs.

High Efficiency

100w laser cleaning machines can clean large areas quickly and efficiently, ensuring that you get the job done in a fraction of the time it would take with traditional methods.

Portable

Portable laser cleaning machines are incredibly convenient, allowing you to clean even hard-to-reach areas with ease.

Handheld

Handheld laser cleaners are perfect for small jobs, as they are easy to maneuver and highly effective.

Affordable

A 100w rust cleaning laser machine is highly affordable, making it an excellent investment for companies of all sizes.

High Power

1000w rust cleaning laser machines are capable of removing even the toughest rust, ensuring that your equipment stays in top condition.

our experience help Boost your business

At Lasersourcing, we are dedicated to providing top-of-the-line cleaning and rust removal equipment for your business. With a wide range of products, including laser paint stripping machines for sale and laser derusting machines, we have the expertise to help you find the right solution for your needs. Our comprehensive product portfolio includes options such as the rod 1000w laser cleaner, which is highly effective in removing even the toughest rust.

Our experience in the industry has allowed us to develop a deep understanding of the market, and we are committed to providing our customers with the best products and service. Whether you’re looking to improve efficiency, reduce costs, or simply keep your equipment in top condition, we have the tools you need to succeed. Contact us today to learn more about how we can help boost your business.

Reliable Shipping Solution

We understand the importance of having a reliable shipping solution when it comes to delivering your laser cleaning equipment. We offer a variety of shipping options to meet your needs, including air freight, sea freight, international express, and international direct line. However, considering factors such as cost, we highly recommend sea freight as the preferred shipping method. Our team has extensive experience in handling sea freight shipments, and we work closely with trusted shipping partners to ensure a smooth delivery process.

Quality Control System

Providing high quality products is essential to building trust and maintaining good relationships with our customers. That’s why we have implemented a strict quality control system to ensure that every product we offer meets the highest quality standards. to seek and provide several benefits to our customers:

- Increased efficiency – High quality products are more efficient, which translates into increased productivity and increased profits for our customers.

- Lower Costs – Investing in quality products reduces the need for frequent repairs and replacements, which ultimately saves our customers money in the long run.

What is the benefit of laser cleaning?

Laser cleaning has several benefits over traditional cleaning methods, including:

Precision: Laser cleaning is a precise and controlled process that can be tailored to specific cleaning tasks. This allows for the removal of contaminants without damaging the underlying material.

Efficiency: Laser cleaning is often faster and more efficient than traditional cleaning methods. For example, laser cleaning can remove rust from metal parts up to four times faster than chemical cleaning methods.

Non-contact: Laser cleaning is a non-contact process, which means that there is no physical contact between the laser and the surface being cleaned. This reduces the risk of surface damage or scratches, making it a safer and more efficient method for cleaning delicate or intricate surfaces.

Versatility: Laser cleaning can be used to clean a wide range of materials, including metals, plastics, ceramics, and glass. This makes it a versatile cleaning tool that can be used in a variety of applications.

Environmental friendliness: Laser cleaning is a dry process that doesn’t require the use of water or chemicals, making it a more environmentally friendly option. The waste material generated during the cleaning process can also be collected and disposed of safely, further reducing its environmental impact.

What can you use laser cleaner for?

A laser cleaner can be used for a variety of cleaning tasks, including:

Rust removal: Laser cleaners can effectively remove rust from metal surfaces, including iron, steel, aluminum, and copper.

Paint removal: Laser cleaners can remove paint from metal, plastic, and other surfaces without damaging the underlying material.

Contaminant removal: Laser cleaners can remove a wide range of contaminants, including oil, grease, mold release agents, and other surface contaminants from a variety of materials.

Surface preparation: Laser cleaners can prepare surfaces for painting, welding, or bonding by removing contaminants and other unwanted materials.

Historical artifact restoration: Laser cleaners can be used to clean and restore delicate or intricate historical artifacts, such as sculptures, paintings, and jewelry.

Glass cleaning: Laser cleaners can remove dirt and other contaminants from the surface of glass, including glassware, lenses, and mirrors.

Electronic component cleaning: Laser cleaners can remove solder and other contaminants from electronic components, such as circuit boards and microchips.

Is laser cleaning efficient?

Yes, laser cleaning is an efficient method for removing contaminants from a variety of materials. Laser cleaning is a precise and controlled process that can be tailored to specific cleaning tasks, making it an effective method for removing contaminants without damaging the underlying material.

Compared to traditional cleaning methods, laser cleaning is often faster and more efficient. For example, laser cleaning can remove rust from metal parts up to four times faster than chemical cleaning methods.

Laser cleaning is also a non-contact process, which means that there is no physical contact between the laser and the surface being cleaned. This reduces the risk of surface damage or scratches, making it a safer and more efficient method for cleaning delicate or intricate surfaces.

Additionally, laser cleaning is a dry process that doesn’t require the use of water or chemicals, making it a more environmentally friendly option. The waste material generated during the cleaning process can also be collected and disposed of safely, further reducing its environmental impact.

Overall, laser cleaning is an efficient and effective method for removing contaminants from a variety of materials, and it is often used in industrial, commercial, and research settings.

Who uses laser cleaning?

Laser cleaning is used by a variety of industries and professionals, including:

Industrial manufacturers: Laser cleaning is often used in industrial manufacturing settings to clean molds, remove rust and other contaminants from metal parts, and clean hard-to-reach areas of machinery and equipment.

Automotive industry: Laser cleaning is used to clean automotive parts, including engine components, transmissions, and brake systems.

Aerospace industry: Laser cleaning is used in the aerospace industry to clean critical parts, such as turbine blades and fuel nozzles, to maintain the safety and efficiency of aircraft.

Art and historical artifact restoration: Laser cleaning is used to clean and restore delicate or intricate historical artifacts, such as sculptures, paintings, and jewelry.

Laboratory and scientific research: Laser cleaning is used in laboratory and scientific research settings to clean glassware, optics, and other delicate instruments.

Military and defense: Laser cleaning is used by the military and defense industries to remove rust and other contaminants from weapons, vehicles, and equipment.

Overall, laser cleaning is a versatile and effective method for removing contaminants from a variety of materials and is used by a wide range of industries and professionals.

What can a laser cleaner clean?

A laser cleaner can clean a variety of materials, including metals, plastics, ceramics, and glass. Some examples of items that can be cleaned with a laser cleaner include:

Metal parts: Laser cleaners can remove rust, paint, and other contaminants from the surface of metal parts, including engine parts, machinery, and equipment.

Plastics: Laser cleaners can remove surface contaminants, such as mold release agents, from plastic parts without damaging the underlying material.

Ceramics: Laser cleaners can remove glaze, stains, and other contaminants from ceramic objects without damaging the underlying material.

Glass: Laser cleaners can effectively remove contaminants, such as dirt and grime, from the surface of glass objects, including glassware, lenses, and mirrors.

Historical artifacts: Laser cleaners can be used to clean delicate or intricate historical artifacts, such as sculptures, jewelry, and paintings.

Electronic components: Laser cleaners can remove solder and other contaminants from electronic components, such as circuit boards and microchips, without damaging the underlying material.

What is laser surface cleaning?

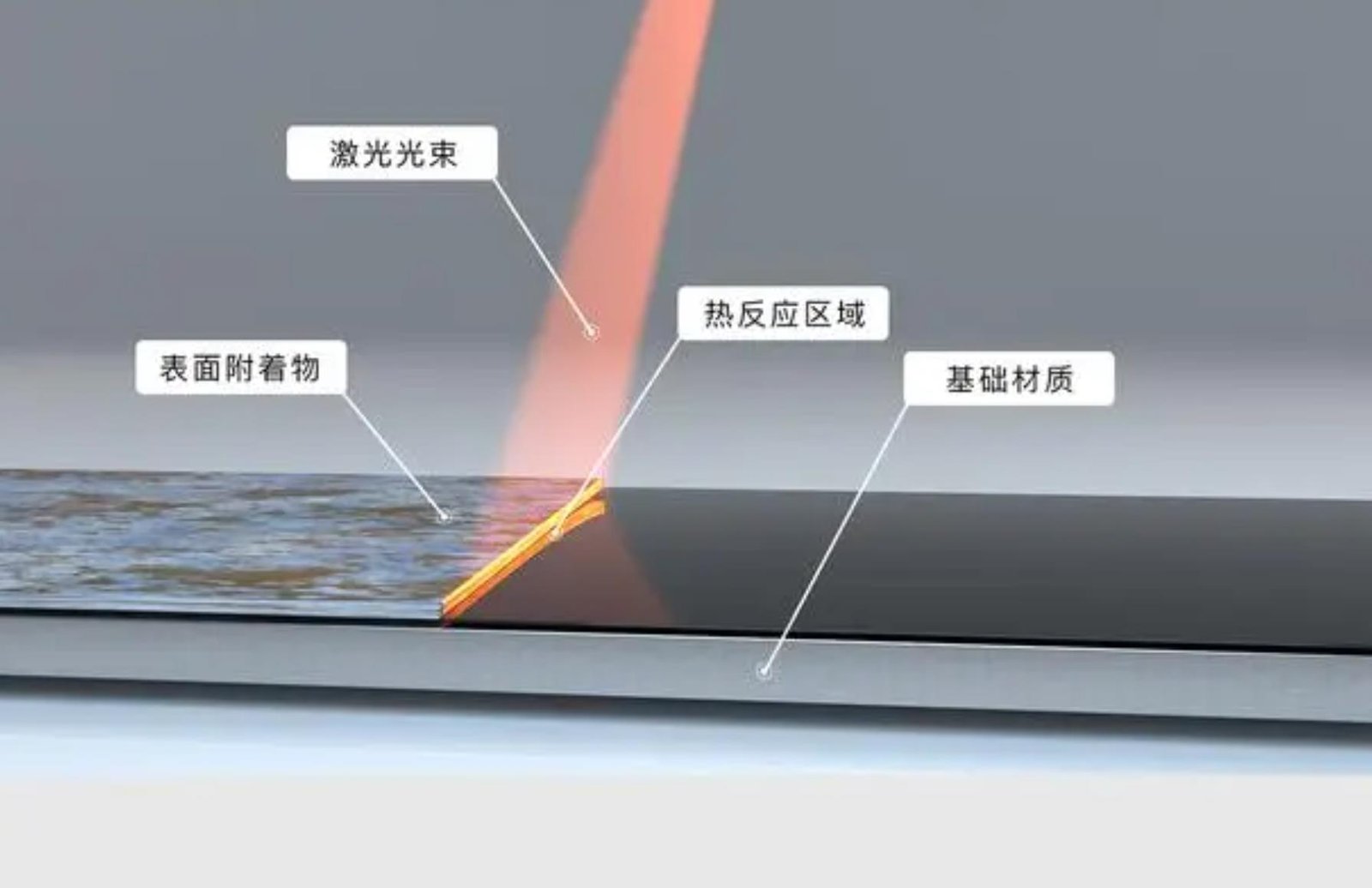

Laser surface cleaning, also known as laser cleaning or laser ablation, is a process that uses a high-powered laser beam to remove contaminants, rust, paint, and other unwanted materials from the surface of a material. The laser beam heats up the surface of the material, causing the contaminants or unwanted material to either evaporate or break down into smaller particles that can be easily removed.

The laser surface cleaning process is similar to laser cleaning, which is used to clean a wide range of materials, including metals, plastics, ceramics, and glass. However, laser surface cleaning is specifically used for removing unwanted materials from the surface of a material, such as rust or paint, rather than cleaning the material itself.

Laser surface cleaning is often used in industrial applications, such as cleaning metal parts, removing coatings from surfaces, and preparing surfaces for painting or welding. It is a precise and effective method for removing unwanted materials from a surface without damaging the underlying material.

It’s important to note that laser surface cleaning should be carried out by trained professionals who understand the properties of the material being cleaned and have experience with the specific type of laser being used. Proper safety measures should be taken to protect operators and others nearby, and the process should be carried out in a well-ventilated area to minimize the environmental impact.

What materials can be laser cleaned?

Laser cleaning can be used to clean a wide range of materials, including metals, plastics, ceramics, and glass. Some examples of materials that can be laser cleaned include:

Metals: Laser cleaning can effectively remove rust, paint, and other contaminants from the surface of metal objects, including iron, steel, aluminum, and copper.

Plastics: Laser cleaning can remove surface contaminants, such as mold release agents, from plastic parts without damaging the underlying material.

Ceramics: Laser cleaning can remove glaze, stains, and other contaminants from ceramic objects without damaging the underlying material.

Glass: Laser cleaning can effectively remove contaminants, such as dirt and grime, from the surface of glass objects, including glassware, lenses, and mirrors.

However, it’s important to note that the suitability of laser cleaning for a particular material will depend on the specific properties of the material and the type of laser being used. For example, some materials may be more sensitive to heat or may have a reflective surface that makes laser cleaning more difficult. It’s important to consult with a professional to determine if laser cleaning is the best method for cleaning a particular material.

What is the disadvantage of laser cleaning?

While laser cleaning has many advantages, there are also some disadvantages to consider:

Cost: Laser cleaning equipment can be expensive, and the cost may be prohibitive for small-scale or occasional cleaning applications.

Safety: Laser cleaning involves the use of high-powered lasers that can pose a safety risk if not handled properly. Proper safety measures must be taken to protect operators and others nearby.

Surface Damage: While laser cleaning is a precise process, it can still cause damage to some surfaces, especially if the laser power density is too high or if the cleaning process is carried out for too long. This can lead to surface damage or even structural damage in some cases.

Limited Applicability: Laser cleaning may not be suitable for all materials and surfaces. Some materials, such as certain plastics or reflective metals, may not respond well to laser cleaning. Additionally, some surfaces may be too delicate or intricate for laser cleaning.

Environmental Impact: While laser cleaning is a dry process that doesn’t require the use of water or chemicals, it still has an environmental impact. The energy required to power the lasers and dispose of any waste materials generated during the cleaning process can contribute to greenhouse gas emissions and other environmental concerns.

It’s important to carefully consider these disadvantages and weigh them against the benefits when deciding whether or not to use laser cleaning for a particular application. It’s also essential to ensure that laser cleaning is carried out by trained professionals who have experience with the specific type of laser being used and the properties of the material being cleaned.

Can you laser clean a car?

Yes, laser cleaning can be used to clean a car. However, it is important to note that laser cleaning is typically used for industrial or commercial applications and may not be practical for routine car cleaning.

Laser cleaning can effectively remove contaminants from the surface of a car, such as dirt, grime, and paint overspray. It can also be used to remove rust from metal surfaces or to clean delicate areas, such as engine parts or electronic components.

However, laser cleaning equipment can be expensive and may require specialized training to operate safely. In addition, the process may take longer than traditional car cleaning methods, which may not be practical for routine car maintenance.

Overall, while laser cleaning can be used to clean a car, it is typically used in industrial or commercial applications rather than for routine car cleaning. For most car owners, traditional car cleaning methods, such as washing and detailing, are likely to be more practical and cost-effective.

Why use laser for deep cleaning?

Laser cleaning is often used for deep cleaning because it can effectively remove contaminants from surfaces that are difficult to clean using traditional methods.

One of the main advantages of using lasers for deep cleaning is that it is a non-contact process. This means that there is no physical contact between the laser and the surface being cleaned, which reduces the risk of surface damage or scratches.

In addition, laser cleaning is a very precise process. The laser beam can be focused to a very small area, allowing it to target specific contaminants without affecting the surrounding area. This is particularly useful when cleaning delicate or intricate surfaces, such as electronics, artwork, or historical artifacts.

Another advantage of laser cleaning is that it can be used on a wide range of materials, including metals, plastics, ceramics, and glass. It is also a dry cleaning process, which means that there is no need for water or other cleaning agents, making it a more environmentally friendly option.

How safe is laser cleaning?

Laser cleaning is safe when performed by trained professionals and using the proper safety equipment. It is important to follow safety guidelines and use protective gear, such as eye protection, when working with laser cleaning equipment.

Can lasers clean glass?

Yes, lasers can be used to clean glass. This process is known as laser cleaning or laser ablation, and it involves using a laser beam to remove contaminants, such as dirt, grease, or other unwanted materials, from the surface of the glass.

The laser beam heats up the surface of the glass, causing the contaminants to evaporate or break down into smaller particles that can be easily removed. This process is very precise and can be controlled to remove only the targeted contaminants without damaging the glass surface.

Laser cleaning is often used in industrial applications, such as cleaning molds, removing paint or rust from metal surfaces, and cleaning delicate or hard-to-reach areas. However, it can also be used in smaller scale applications, such as cleaning glassware in laboratories or removing stains from antique glass objects.

It’s important to note that laser cleaning should be done by professionals who are trained in using the equipment and understand the potential hazards associated with laser use.

Does laser cleaning remove material?

Yes, laser cleaning can remove material from a surface. Laser cleaning, also known as laser ablation, uses a high-powered laser beam to remove contaminants from the surface of a material by vaporizing or breaking them down into smaller particles that can be easily removed.

However, the extent to which material is removed depends on several factors, such as the type of laser, the power density of the laser beam, the duration of the cleaning process, and the type of material being cleaned. In some cases, laser cleaning may only remove the contaminants from the surface without significantly affecting the underlying material. In other cases, it may remove a small layer of the material along with the contaminants.

It’s important to note that laser cleaning is a precise process that can be controlled to remove only the targeted contaminants without damaging the underlying material. However, if the laser power density is too high or if the cleaning process is carried out for too long, it can cause damage to the material being cleaned.

What is laser cleaning process?

The laser cleaning process typically involves the following steps:

Preparation: The surface to be cleaned is prepared by removing any loose debris or particles.

Selection of Laser: The appropriate type of laser is selected based on the properties of the material being cleaned, such as its composition, thickness, and surface finish.

Calibration: The laser is calibrated to ensure that the power density of the laser beam is optimized for the specific cleaning task.

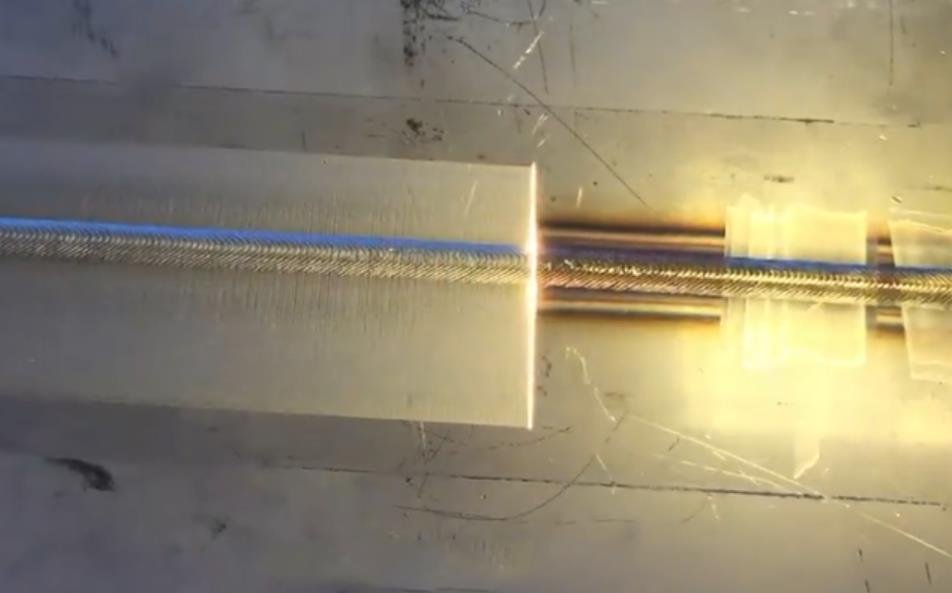

Cleaning: The laser beam is directed at the surface of the material, and the cleaning process begins. The laser beam is scanned across the surface of the material, and the intensity and duration of the laser beam are controlled to remove the contaminants or unwanted material without damaging the underlying material.

Post-cleaning: Once the cleaning process is complete, the surface of the material is inspected to ensure that all contaminants or unwanted material have been removed.

How does laser rust removal machine work?

A laser rust removal machine works by using a high-powered laser beam to vaporize rust and other surface contaminants from the surface of a metal object. The process is also known as laser ablation, which involves the use of laser energy to remove material from a surface.

The laser beam is directed at the surface of the metal, where it heats up the rust and other contaminants to a very high temperature. This causes the rust to vaporize and break down into smaller particles that can be easily removed. The laser beam is very precise and can be controlled to remove only the rust and other contaminants without damaging the underlying metal.

The laser rust removal process typically involves the following steps:

Preparation: The metal object to be cleaned is prepared by removing any loose debris or particles.

Selection of Laser: The appropriate type of laser is selected based on the properties of the metal being cleaned, such as its composition, thickness, and surface finish.

Calibration: The laser is calibrated to ensure that the power density of the laser beam is optimized for the specific cleaning task.

Cleaning: The laser beam is directed at the surface of the metal, and the cleaning process begins. The laser beam is scanned across the surface of the metal, and the intensity and duration of the laser beam are controlled to remove the rust and other contaminants without damaging the underlying metal.

Post-cleaning: Once the cleaning process is complete, the surface of the metal is inspected to ensure that all rust and other contaminants have been removed.

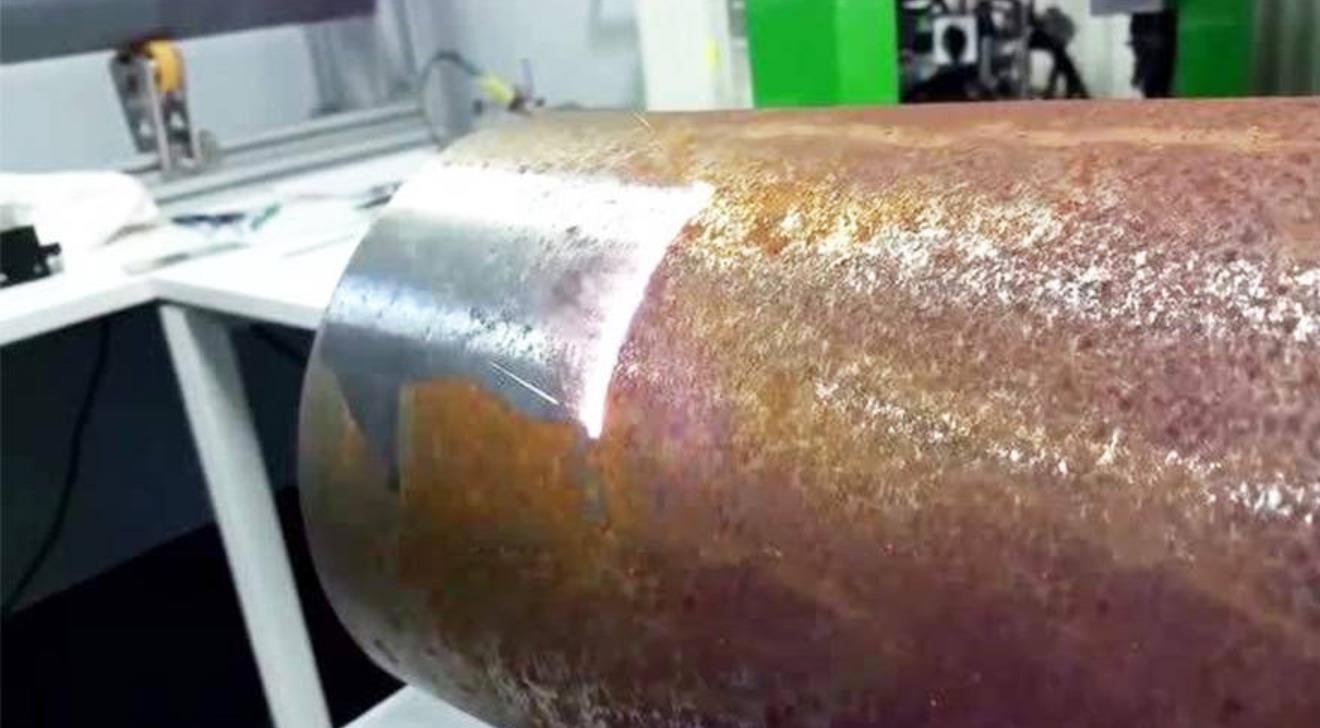

Laser rust removal is often used in industrial applications, such as cleaning metal parts and equipment, as well as in the restoration of antique metal objects. It is a precise and effective method of removing rust and other surface contaminants without damaging the underlying metal.

How does rust removal work?

Rust removal works by using various methods to remove the rust from a metal object or surface. Rust is a form of corrosion that occurs when iron or steel is exposed to air and moisture, which causes the metal to oxidize and form a reddish-brown coating.

There are several methods for rust removal, including mechanical methods, chemical methods, and electrochemical methods.

Mechanical methods: Mechanical methods involve physically removing the rust from the metal surface using tools such as wire brushes, sandpaper, or abrasive blasting. This method is effective for removing surface rust but may not be suitable for removing deep or extensive rust.

Chemical methods: Chemical methods involve using chemicals to dissolve the rust from the metal surface. This method is effective for removing deep or extensive rust but may require careful handling and disposal of the chemicals.

Electrochemical methods: Electrochemical methods involve using an electric current to remove the rust from the metal surface. This method is effective for removing rust from hard-to-reach areas and may be suitable for delicate or intricate metal objects.

Laser rust removal is another method that uses a high-powered laser beam to vaporize the rust from the metal surface. This process is also known as laser ablation and is a precise and effective method for removing rust without damaging the underlying metal.

Once the rust has been removed, the metal surface should be cleaned and protected to prevent future rust formation. This may involve applying a rust inhibitor, a protective coating, or using a rust-resistant metal alloy.

Request A Free Quote

Have any questions about laser parts?

Don’t hesitate to contact us. Lasersourcing’s product specialists are very happy to help you and provide a variety of flexible and reliable solutions to help you solve various problems.

Tel

+86-15370952128

lasersourcing@hotmail.com

15370952128

+86-15370952128