What Is Hypertherm ?

Hypertherm is a leading provider of advanced plasma systems for industrial cutting applications. The company’s products range from manual handheld plasma cutters to automated cutting systems with robotic software, CNC motion control, and CAM nesting software.

Hypertherm plasma cutters are widely used in a variety of industries, including metal fabrication, automotive repair, shipbuilding, and construction. They are known for their high-performance, versatility, and ease of use, and are capable of cutting a range of materials including mild steel, aluminum, stainless steel, and more.

Where are Hypertherm plasma cutters made?

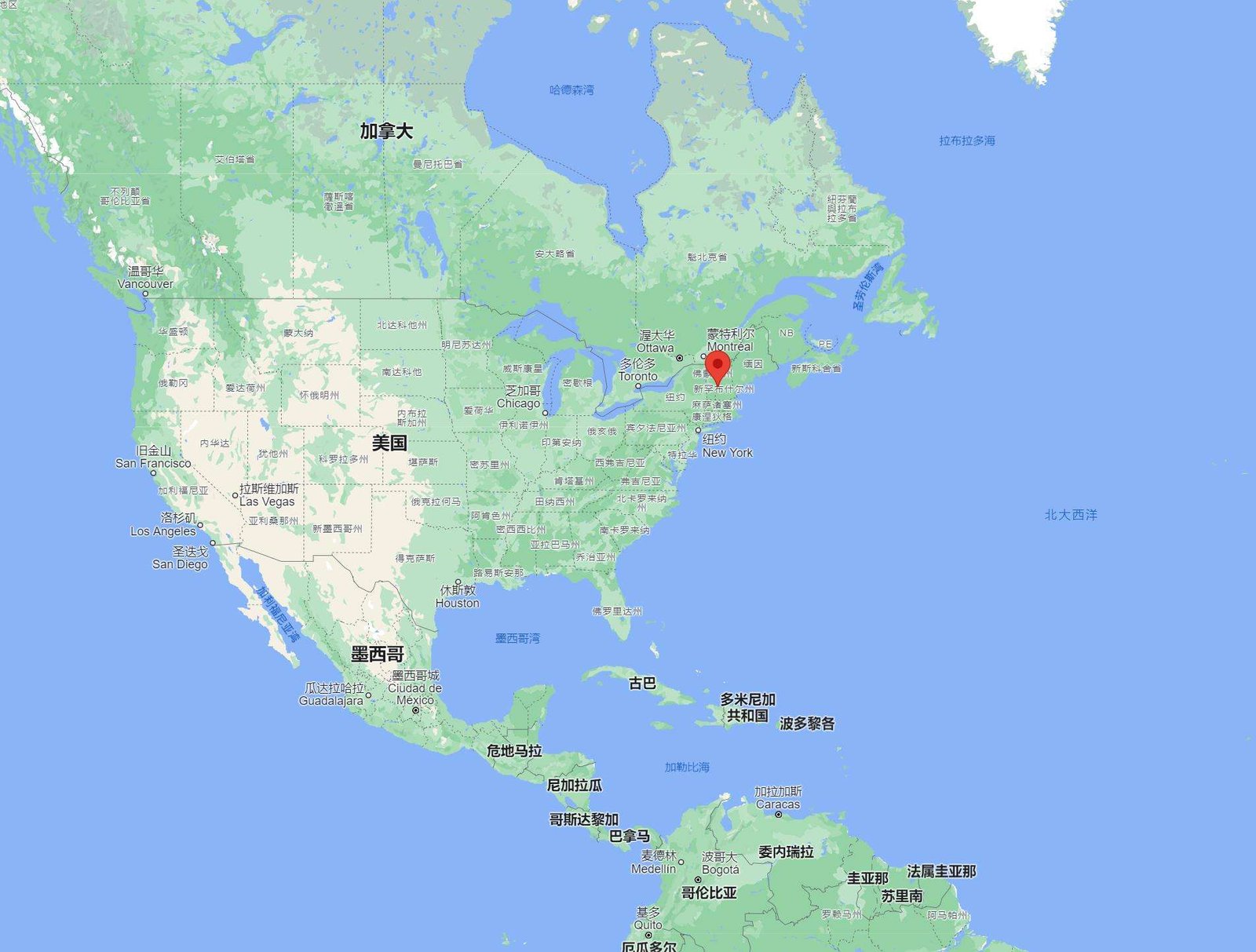

Hypertherm is a global manufacturer of plasma cutting systems, with a product line that includes its popular Powermax systems. The company’s technology and business operations are headquartered in Hanover, New Hampshire, USA, where its main manufacturing facility is located. From this base, Hypertherm provides its cutting-edge products and services to customers in various industries around the world.

Hypertherm Contact is the customer support arm of Hypertherm, the world’s leading provider of plasma cutting systems. The company offers this service to ensure businesses have access to the reliability and support they need to get the best results from their Hypertherm plasma cutting systems.

Hypertherm has a global presence, in addition to its corporate headquarters in Hanover, New Hampshire, USA, where it operates its main production facilities and conducts most of its research and development. In addition to the headquarters, Hypertherm has sales and service centers in many countries, including Canada, Mexico, Brazil, China, India, Australia, Europe and other countries.

Hypertherm and Lincoln Electric are both well-known manufacturers of plasma cutting systems. While both companies offer high quality products, there are some differences between their plasma cutting machines.

Hypertherm plasma cutters are mainly on the high end, with a higher average price. Known for their durability, performance and versatility. They are used in a wide variety of industries, including metal fabrication, automotive repair, shipbuilding and construction. Hypertherm plasma cutters are designed to handle a wide range of cutting applications, from light-duty cutting to heavy-duty production environments.

Lincoln Electric’s plasma cutting machines are also highly regarded in the industry, primarily going the cost-performance route, and are known for their reliability and affordability. The company’s plasma cutting machines are used in a wide range of industries including automotive, construction and metal fabrication. Lincoln Electric’s plasma cutters are designed to be user-friendly and easy to operate, so they are a good choice for companies that need a high-quality plasma cutter at a low price.

Ultimately, the choice between Hypertherm and Lincoln Electric plasma cutters will depend on the specific needs and requirements of your business. Both companies offer high quality products, so it’s important to carefully consider your cutting needs and budget before making a decision.

Hypertherm and Thermal Dynamics are both leading cutting technology companies that provide high-quality cutting equipment and technology.

Hypertherm, established in 1968 and headquartered in New Hampshire, USA, is a global leading high-temperature plasma cutting technology company. Their product line includes high-speed plasma cutters, laser cutters, and flame cutters, among others. Their products focus on providing efficient and accurate cutting solutions for industries such as metal fabrication, shipbuilding, and military equipment manufacturing.

Thermal Dynamics, established in 1949 and headquartered in Vermont, USA, is a company specializing in flame cutting technology. Their product line includes flame cutters, laser cutters, and plasma cutters, among others. Their products focus on providing cost-effective and efficient cutting solutions for industries such as metal fabrication, oil and gas, and metallurgy.

In terms of product positioning, Hypertherm focuses more on high-temperature plasma cutting technology and provides more efficient and accurate cutting solutions, while Thermal Dynamics focuses more on flame cutting technology and provides more cost-effective and user-friendly cutting solutions.

Hypertherm, established in 1968 and headquartered in New Hampshire, USA, is a global leading high-temperature plasma cutting technology company. Their product line includes high-speed plasma cutters, laser cutters, and flame cutters, among others. Their products focus on providing efficient and accurate cutting solutions for industries such as metal fabrication, shipbuilding, and military equipment manufacturing.

Miller, established in 1929 and headquartered in Wisconsin, USA, is a leading manufacturer of welding and cutting equipment. Their plasma cutting product line includes handheld plasma cutters, automated plasma cutters, and plasma cutting systems, among others. Their products focus on providing reliable and versatile cutting solutions for industries such as metal fabrication, construction, and maintenance and repair.

In terms of product positioning, Hypertherm focuses more on high-temperature plasma cutting technology and provides more efficient and accurate cutting solutions, while Miller focuses more on versatility and reliability, offering a wider range of plasma cutting options for a variety of industries.

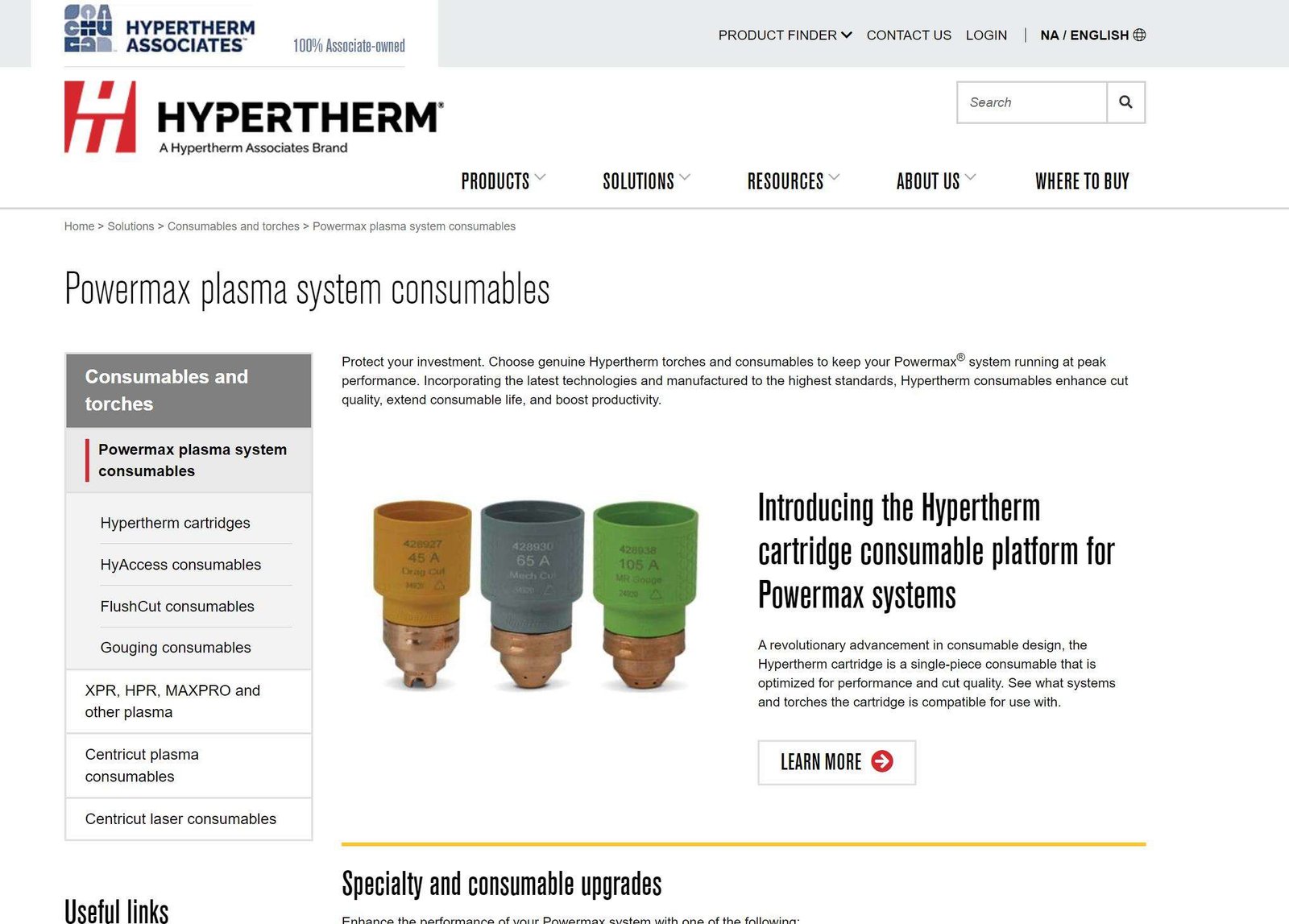

Alternative Consumables For Hypertherm

Where To Buy Hypertherm Consumables ?

1.Directly From Hypertherm Company

Customers can purchase spare parts directly from Hypertherm by contacting the company directly or visiting their official online shop.

2.Authorized Distributors

Hypertherm has authorized distributors all over the world who stock and sell Hypertherm spare parts. Customers can find a list of authorized distributors on Hypertherm’s website.

3.Find Suppliers Online

Many suppliers will promote their business online, they may have online stores at Amazon; Alibaba, or they have their own stand-alone websites. Just provide them with the part number you wish to get. Usually they will offer more cost-effective spares parts. Customers can easily find them through the web.

4.Local Dealers

Some local dealers may also carry alternative spare parts for Bystronic laser cutting machine. Customers can check with local dealers in their area for availability and pricing information.