Title: “Unlocking Creativity: A Comprehensive Guide to Laser Engraver Machines”

I. Introduction

A. The rising popularity of laser engraver machines

In recent years, the use of laser engraver machines has skyrocketed, becoming a vital tool for businesses and individuals alike. Their surge in popularity can be attributed to factors such as improved technology, more affordable pricing, and the increasing demand for personalized and customized products. As laser engraving technology becomes more accessible, it is empowering entrepreneurs, artists, and hobbyists to create unique and intricate designs on a wide variety of materials.

B. How laser engraving technology is revolutionizing various industries

Laser engraving technology has had a significant impact on several industries, transforming the way products are designed, manufactured, and customized. Here are a few examples of industries that have been revolutionized by laser engraver machines:

- Jewelry: Laser engraving has enabled jewelers to create intricate designs and patterns on metal surfaces, allowing for personalized and unique jewelry pieces. Laser engravers can also be used to inscribe messages or dates on rings, pendants, and other items, adding sentimental value to these pieces.

- Woodworking: Woodworkers can now easily etch intricate patterns and designs onto wood surfaces, adding an artistic touch to their creations. Laser engraver machines can also be used to create custom signage, furniture, and decorative items, opening up new avenues for creative expression in the woodworking industry.

- Manufacturing: In the manufacturing sector, laser engraving technology is used to mark parts with identification numbers, barcodes, and other essential information for quality control and traceability purposes. The ability to create permanent, high-quality markings has streamlined processes and increased efficiency in many manufacturing industries.

- Fashion and apparel: Laser engraving machines have given designers the ability to create unique and intricate patterns on fabrics, leather, and other materials, enhancing the aesthetics of clothing and accessories. Additionally, laser cutting technology allows for precise, clean cuts, enabling the creation of intricate designs and shapes in the fashion industry.

- Promotional products: Laser engraver machines have become indispensable in the promotional products industry, as businesses can now easily customize items such as pens, keychains, and awards with their logos and branding, creating memorable and eye-catching marketing materials.

As laser engraving technology continues to advance, it is poised to revolutionize even more industries, driving innovation and opening up new possibilities for creative expression and customization.

II. Understanding laser engraver machines

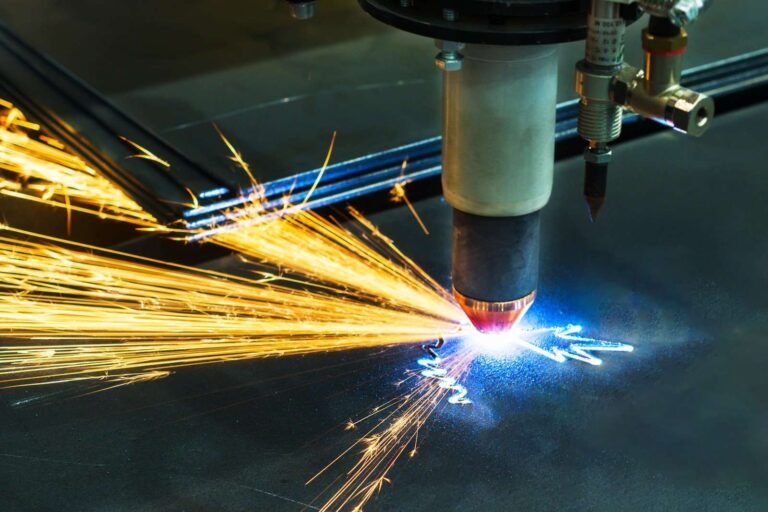

A. The basic principles behind laser engraving

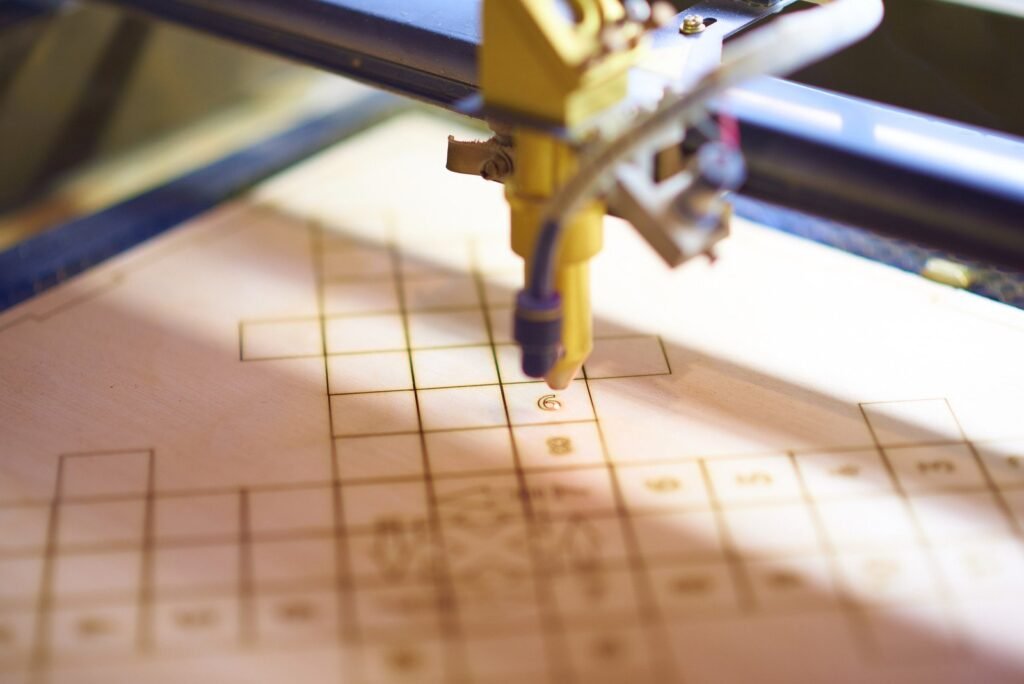

Laser engraving is a process that uses a concentrated beam of light to create detailed designs and patterns on a material’s surface. The laser engraver machine directs the laser beam onto the material, where the heat generated by the beam either removes material (in the case of engraving) or changes its color (in the case of etching). The machine controls the movement of the laser beam, guiding it along the desired design path. The laser’s intensity, speed, and focus can be adjusted to achieve varying levels of detail and depth.

There are two main methods of laser engraving: vector engraving and raster engraving. Vector engraving follows the design’s outline, creating crisp lines and sharp edges, making it ideal for logos and text. Raster engraving, on the other hand, fills in the design area with a series of closely spaced dots, creating an image with varying shades and textures, suitable for photographs and detailed graphics.

B. Comparing CO2, fiber, and diode laser engravers

There are three primary types of laser engraver machines, each with its unique strengths and applications:

CO2 laser engravers

These machines use a gas laser with a mixture of carbon dioxide, nitrogen, helium, and other gases. CO2 lasers are the most versatile and widely used type of laser engraver due to their ability to work with a variety of materials, including wood, acrylic, glass, leather, fabric, and some types of plastic. They are particularly popular for woodworking, glass engraving, and creating custom signage.

Fiber laser engravers

Fiber lasers use a solid-state laser with a glass or crystal core doped with rare-earth elements. They are known for their high power, efficiency, and excellent beam quality, making them well-suited for metal engraving, etching, and marking applications. Fiber laser engravers are commonly used in industries such as aerospace, automotive, and electronics, where precision and durability are crucial.

Diode laser engravers

Diode lasers use semiconductor technology to produce a laser beam. While they generally have a lower power output compared to CO2 and fiber lasers, they are more compact and energy-efficient, making them suitable for smaller-scale applications and hobbyist use. Diode laser engravers are best suited for materials like plastic, rubber, and thin, coated metals, but may struggle with thicker or denser materials.

III. Applications and possibilities with laser engraver machines

A. Personalization and customization of products

One of the most significant advantages of laser engraver machines is their ability to personalize and customize a wide range of products. This has become increasingly popular in recent years, as consumers seek unique, one-of-a-kind items that reflect their tastes and preferences. Some examples of product personalization and customization using laser engravers include:

Custom phone cases: Engraving unique designs or monograms on phone cases to create personalized accessories.

Personalized jewelry: Engraving names, initials, or special messages on rings, bracelets, and pendants for meaningful gifts.

Custom awards and trophies: Creating bespoke awards and trophies by engraving logos, event names, and recipient details.

Promotional items: Customizing pens, keychains, and other promotional items with a company’s logo or branding.

B. Art and creative design

Laser engraver machines have opened up new possibilities for artists and designers by allowing them to create intricate, detailed designs on various materials. Some examples of artistic applications for laser engravers include:

Wood art: Etching intricate patterns and designs onto wood surfaces, creating unique decorative items and custom woodwork.

Glass art: Engraving delicate designs on glass panels, mirrors, and drinkware for a touch of elegance and sophistication.

Textile design: Cutting and engraving intricate patterns on fabrics and leather to create custom clothing and accessories.

Mixed media artwork: Combining different materials, such as wood, acrylic, and metal, to create multi-layered, dimensional artwork.

C. Manufacturing and industrial applications

Laser engraver machines have become indispensable in many manufacturing and industrial settings. Their precision, efficiency, and ability to create permanent markings have made them an essential tool for various applications, including:

Part identification: Engraving part numbers, serial numbers, and barcodes on components for tracking and quality control purposes.

Safety and warning labels: Creating durable, high-contrast labels and signs for machinery, equipment, and workspaces to ensure compliance with safety regulations.

Tooling and fixtures: Precisely engraving measurement markings and alignment guides on tools and fixtures to improve manufacturing processes and accuracy.

Branding and packaging: Engraving logos and product information on items or packaging materials, enhancing brand recognition and consumer engagement.

IV. Choosing the right laser engraver machine for your needs

A. Factors to consider when buying a laser engraver

When selecting a laser engraver machine, it’s essential to consider several factors to ensure that the machine meets your needs and requirements. Some factors to consider include:

Material compatibility: The type of materials you plan to work with will significantly influence the kind of laser engraver you should choose. CO2 lasers are versatile and suitable for various materials, while fiber lasers excel at metal engraving, and diode lasers work best with plastics and thin metals.

Work area size: The size of the machine’s work area will determine the maximum dimensions of the materials you can engrave. Choose a machine with a work area large enough to accommodate your projects and materials.

Laser power: The power of the laser will affect the engraving speed and the depth of the engraving. Higher-powered lasers can engrave more quickly and deeply, but they may also be more expensive and consume more energy.

Software compatibility: Ensure that the laser engraver is compatible with the design software you prefer to use, as this will streamline the design and engraving process.

Safety features: Look for machines with built-in safety features, such as emergency stop buttons, ventilation systems, and protective enclosures, to minimize potential hazards.

B. Price ranges and budget considerations

Laser engraver machines can vary significantly in price, depending on factors such as the type of laser, the machine’s size and power, and the included features. Small, entry-level machines for hobbyists can start at a few hundred dollars, while professional-grade machines with larger work areas and more powerful lasers can range from several thousand to tens of thousands of dollars.

When determining your budget for a laser engraver machine, consider factors such as the materials you plan to work with, the size of your projects, and your desired level of precision and engraving quality. Additionally, don’t forget to account for ongoing costs, such as replacement parts, maintenance, and energy consumption, when making your decision.

V. Tips for using your laser engraver machine effectively

A. Safety precautions and maintenance

To ensure the safe and efficient operation of your laser engraver machine, it’s essential to follow these safety precautions and maintenance tips:

Always wear protective eyewear when operating the machine to shield your eyes from the laser beam and potential debris.

Ensure proper ventilation in the work area, as the engraving process can produce fumes and smoke. Installing an exhaust system or using an air filter will help keep the air clean and safe.

Keep the work area clean and free of clutter to minimize fire hazards and ensure proper laser focus.

Regularly inspect and clean the laser’s optics, such as lenses and mirrors, to maintain optimal performance and prevent damage.

Lubricate the machine’s moving parts periodically to ensure smooth operation and reduce wear and tear.

Always follow the manufacturer’s guidelines for maintenance, including any recommended service intervals or part replacements.

B. Maximizing engraving quality and precision

To achieve the best engraving results, follow these tips for maximizing quality and precision:

Choose the right laser engraver for your materials, as different types of lasers work best with specific materials.

Properly secure the material to the work table to prevent movement during the engraving process, ensuring consistent results.

Regularly calibrate the machine and fine-tune the laser’s focus to maintain optimal engraving quality.

Experiment with different engraving settings, such as power, speed, and resolution, to find the optimal combination for each material and design.

Use high-quality design files and software to ensure crisp, clear engraving results.

C. Expanding your skills and exploring new materials

As you become more comfortable with your laser engraver machine, challenge yourself to expand your skills and explore new materials:

Experiment with different materials to discover new creative possibilities, such as engraving on glass, fabric, or even edible items like chocolate or fruit.

Combine different materials in a single project to create multi-layered, mixed-media artwork.

Attend workshops, webinars, or online courses to learn new techniques and improve your engraving skills.

Connect with other laser engraving enthusiasts through online forums, social media groups, or local meetups to share ideas, inspiration, and tips.

Stay informed about the latest developments in laser engraving technology, software, and materials to continue expanding your creative potential.

By following these tips and continually pushing your creative boundaries, you’ll be able to make the most of your laser engraver machine and unlock its full potential.

VI. Frequently asked questions about laser engraver machines

A. How to use a laser engraver machine

To use a laser engraver machine, follow these steps:

1.Create or import a design file: Using compatible design software, create a new design or import an existing one. Make sure the design is in a format supported by your laser engraver machine.

2.Set up the machine: Ensure the machine is clean and well-maintained, following the manufacturer’s guidelines for maintenance and upkeep.

3.Secure the material: Place the material to be engraved on the work table and secure it firmly, preventing movement during the engraving process.

4.Adjust the machine settings: Based on the material and desired engraving depth, adjust the machine settings such as power, speed, and resolution. This may require some experimentation to find the optimal settings for each material and design.

5.Send the design file to the machine: Transfer the design file to the laser engraver machine, following the manufacturer’s instructions for your specific model.

6.Perform a test run (optional): Before starting the engraving process, you may want to perform a test run on a scrap piece of material to ensure the settings are correct and the design appears as intended.

7.Start the engraving process: Begin the engraving process and monitor the progress closely, making any necessary adjustments to the settings or design as needed. Be sure to follow all safety precautions, such as wearing protective eyewear, during the engraving process.

By following these steps, you can effectively use a laser engraver machine to create intricate designs on various materials, expanding your creative potential and enhancing the quality of your work.

B. How does a laser engraver machine work

A laser engraver machine works by using a focused beam of light, or laser, to create intricate designs on a material’s surface. The process involves the laser heating the material, either removing it through vaporization (engraving) or altering its color (etching) to produce the desired pattern or design.

The laser engraver machine operates under computer control, with the design software dictating the laser’s movements along a predetermined path. The software also manages the laser’s intensity, speed, and focus, allowing for precise adjustments to create varying levels of detail and depth in the engraving.

Various types of laser engraver machines exist, such as CO2, fiber, and diode lasers, each with its unique capabilities and material compatibilities. These machines have found applications in numerous industries, including personalization and customization of products, art and creative design, and manufacturing processes, offering endless possibilities for creativity and innovation.

C. What does a marking machine laser engraver do

A marking machine laser engraver is a specialized type of laser engraving equipment designed to create permanent, high-contrast markings on a variety of materials. These machines find widespread use in industrial settings for various purposes, including part identification, branding, and compliance labeling.

Marking machines typically utilize fiber or diode lasers, which are known for their ability to create durable markings resistant to wear, heat, and corrosion. This ensures that the markings remain legible and intact even under harsh conditions, making them ideal for industries such as automotive, aerospace, electronics, and medical devices.

In addition to their industrial applications, marking machine laser engravers can also be used for artistic and decorative purposes, creating intricate designs on materials like metal, glass, and ceramics. Overall, these machines provide a versatile and efficient solution for producing long-lasting, high-quality markings on a wide range of materials.

D. What is the difference between a laser engraver and a CNC machine

The primary difference between a laser engraver and a CNC machine lies in their respective working principles and applications.

A laser engraver uses a focused beam of light (laser) to remove or alter the surface of a material, creating designs, patterns, or markings. This process involves heating the material, either vaporizing it (engraving) or changing its color (etching), to produce the desired outcome. Laser engravers are well-suited for intricate, detailed designs and can work with a wide range of materials, including wood, acrylic, glass, and certain metals.

On the other hand, a CNC (computer numerical control) machine employs a cutting tool, such as a router, mill, or lathe, to remove material along a predetermined path. This process creates three-dimensional objects or parts by shaping the material according to the design input. CNC machines are often used for cutting and shaping larger, more robust materials like metal, wood, and plastic.

While both machines operate under computer control and can achieve high levels of precision, they serve different purposes and have distinct material compatibilities. Laser engravers excel in creating detailed and intricate designs, whereas CNC machines are better suited for shaping and cutting more substantial materials. Choosing between the two will largely depend on the specific requirements of your project and the materials you intend to work with.

E. How long does a laser engraver machine last

The lifespan of a laser engraver machine depends on several factors, including the machine’s quality, maintenance, usage, and the specific type of laser used. With proper care and maintenance, a high-quality laser engraver can last many years.

CO2 lasers typically have a longer life expectancy compared to diode lasers, with the laser tube lasting anywhere between 5,000 to 20,000 hours, depending on the quality and usage. Fiber lasers have a much longer lifespan, often exceeding 100,000 hours. Regular maintenance, such as cleaning the optics, lubricating moving parts, and replacing worn components, will help extend the life of your laser engraver machine.

VII. Conclusion

A. Embracing the future of laser engraving technology

Laser engraving technology has come a long way since its inception, and its continued evolution promises even greater advancements in the future. As the technology becomes more accessible and affordable, we can expect to see further growth in its applications and capabilities. By embracing the potential of laser engraving technology, businesses, artists, and hobbyists can stay at the forefront of innovation, creating new and exciting opportunities for their work.

B. The impact of laser engraver machines on creativity and innovation

Laser engraver machines have had a profound impact on creativity and innovation across various industries, from art and design to manufacturing and beyond. These machines have revolutionized the way we create and customize products, allowing for intricate designs, personalization, and improved production efficiency. By expanding our creative horizons and providing new ways to manipulate materials, laser engraver machines have unlocked an entirely new realm of possibilities for artists, designers, and manufacturers alike.

As we look to the future, the ongoing development of laser engraving technology will continue to push the boundaries of what is possible, inspiring even greater creativity and innovation across a wide range of applications.