The Ultimate Guide For Precitec Laser Heads and Consumables

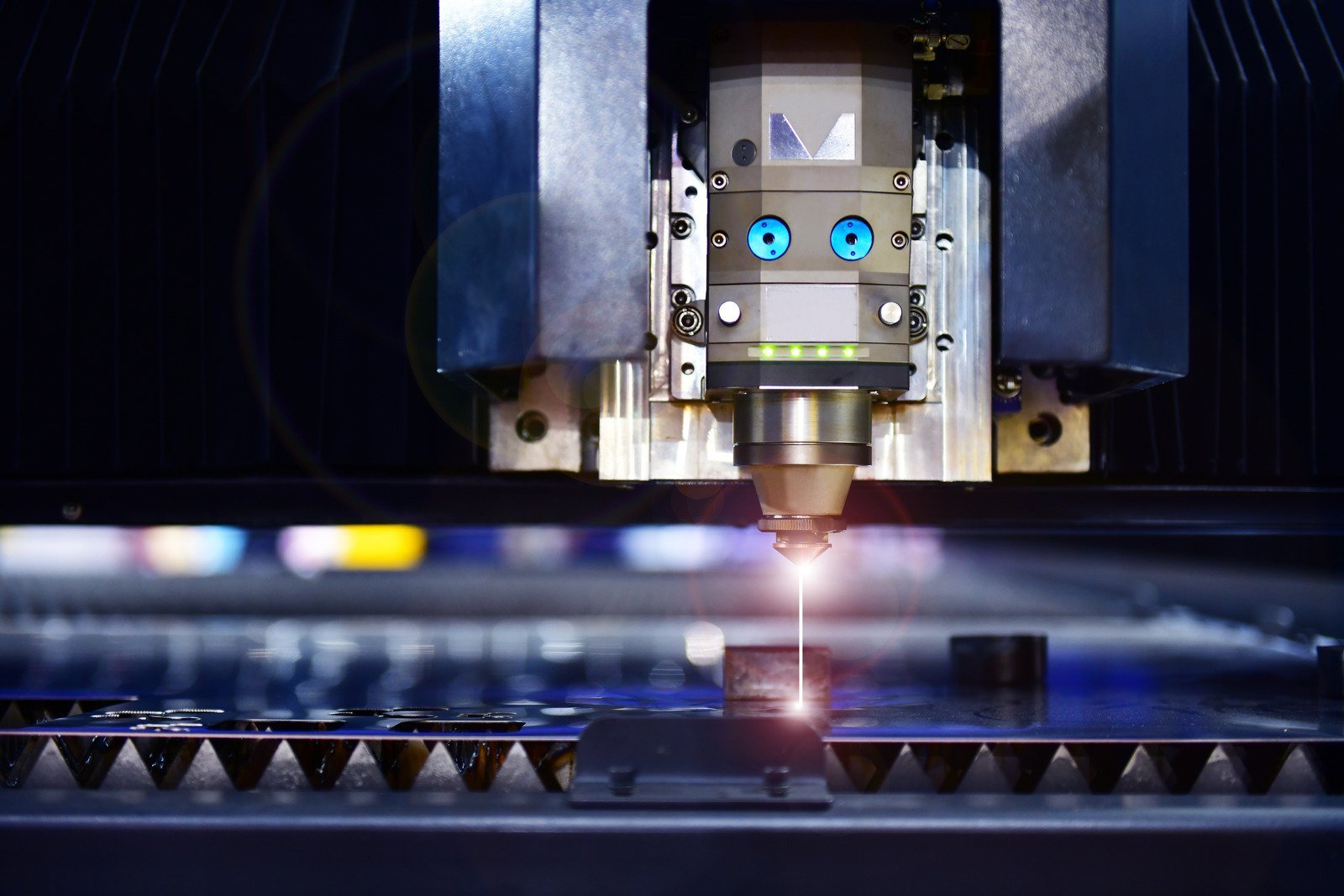

Precitec Laser Heads

ProCutter Thunder:

Data:max. laser power: 6.6 kW

Focal length collimation 2D | 3D: 100 mm

Focal lengths focusing 2D: 150 mm, 200 mm

Focal lengths focusing 3D: 200 mm

NAmax: 0.12

Dimensions (WxD): 116 x 113 mm

Vertical focus adjustment range: +15 to -20 mm

The ProCutter Thunder offers efficient and economical laser cutting in the medium power range for flatbed and 3D applications. Its cutting head provides stable, precise operation, with a highly dynamic drive for minimal non-productive times and flexibility. The focus position is automatically controlled for outstanding results on various material thicknesses. The 2D version is ideal for flatbed and simple tube/profile cutting, while the 3D version suits professional tube/profile cutting and demanding free-form applications. Key advantages include high cutting-edge quality due to an ultra-stable distance sensor system, ensuring smooth edges even at high accelerations, and low service costs with less downtime, thanks to easy access optics and built-in protective glasses extending the service life of valuable optics.

ProCutter Thor:

Data:

max. laser performance: 20 kW

Focal length collimation: 100 mm

Focal length focusing: 200 mm

NAmax: 0.13

Dimensions (WxD): 137 mm x 185 mm

Vertical focus adjustement range: +20 mm bis -35 mm

The ProCutter Thor features a dust-tight, one-piece housing for stable processes and long-lasting optics, excelling in medium to thick sheet cutting. Its patented “Clean Back” design positions service-relevant access at the rear, the cleanest area of the cutting system. Key advantages include permanently excellent cutting quality and flexibility, with an ultra-stable distance sensor system for smooth edges even at high acceleration values. The focus position adjustment ensures low non-productive times and allows flexible, precise cutting of various thicknesses and materials. The ProCutter Thor outperforms its class with higher focus position travels and process-stable thick material processing. Low service costs and downtime are ensured by easy access to optics, halved time for optic changes, and built-in protective glasses that extend the service life of valuable optics.

ProCutter 2.0:

Data:

max. laser power: 40 kW (with wave lengths of 1030 – 1090 nm)

Collimating focal length: 100 mm, Focus lengths: 150, 200 mm

NAmax: 0.18 (for 40 kW)

Dimension (WxD): 96 x 134 mm

Weight: 4.9 kg (FF150)

The ProCutter 2.0 offers exceptional performance and automation in flatbed and tube cutting systems, handling up to 40 kW laser power. It enables previously inaccessible cutting processes, eliminating the need to choose between high quality and high speed. This results in increased machine utilization, a shorter payback period, and reduced rework.

The new ProCutter 2.0 achieves cutting speeds previously thought impossible, working trouble-free up to 40 kW laser power due to its advanced cooling concept and extended travel paths. The optimized design allows for a 25% increased cutting speed compared to its predecessor.

Compatible with all laser sources, it maintains consistent cut quality even at high laser powers. The compact and lightweight cutting head is suitable for bevel cutting. Integrated smart sensors ensure constant component quality and process stability, compensating for fluctuations without operator intervention. PierceTec technology delivers consistent hole and surface quality while reducing rework and saving cycle time and operating costs.

Smart sensors monitor critical components and cutting process parameters, enabling planned maintenance and efficient spare part utilization. The ProCutter APP allows mobile access to data, displaying the current status and error messages.

ProCutter Zoom 2.0:

Data:

max. laser power: 12 kW (with wave lengths of 1030 – 1090 nm)

Magnification ratio: 1.2 / 1.5 / 2.0 / 2.5 / 3.0 / 3.5 / 4.0

NAmax: 0.13

Dimension (WxD): 126 x 133 mm

Weight: 7.6 kg

The ProCutter Zoom 2.0 cutting head offers maximum flexibility and performance in a compact design. Ideal for laser powers up to 12 kW, it is the ultimate all-rounder for flatbed systems, providing the perfect beam for all materials and thicknesses.

Advantages include maximum flexibility and output, with optimal process results in both quality and speed. Its extensive traverse paths and variable laser spot magnification enable the best cutting and piercing processes for various material types and thicknesses, resulting in up to 35% speed advantages in some laser cutting areas compared to fixed magnification products. This is especially beneficial for thick material processing, yielding excellent roughness and squareness.

The cutting head reduces rework and unit costs by compensating for fluctuations in the process or material quality without operator intervention. It minimizes splashes during piercing, shortens the duration, and preserves the component surface, sparing wearing parts and reducing follow-up costs. A range of sensors provide continuous information on core components, reducing machine downtimes.

SolidCutter:

Data:

max. laser power: 4 kW (wavelengths 1030 – 1090 mm)

Collimation focal lengths: 75, 100 mm, Focus lengths: 75, 100, 125 mm

Dimensions 163 x 132 mm

NAmax: 0.16 at FC75, NAmax: 0.12 at FC100

Stroke: ± 15 mm

Weight: 5.0 kg

The SolidCutter is designed for stable and user-friendly operation in automated laser systems, excelling in the 3D machining of complex individual contours on metallic materials.

Key advantages include high productivity and flexibility in 24/7 operations. Primarily used in the automotive industry, robot-guided laser cutting enables flexible and highly productive processing of high-strength body components and profiles, such as roof rail openings and vehicle door contours. Its compact and weight-optimized design allows for high dynamics and freedom of movement, while the integrated fine adjustment of the working distance compensates for any inaccurate web guidance, ensuring consistently high cutting quality at high feed rates.

Simple, robust, and reliable, the SolidCutter is ideal for complex production lines operating under challenging conditions. Its long service life, slim design, and easily accessible media connections make it cost-effective for automated system integration. The proven technology guarantees economic efficiency by minimizing rework and eliminating set-up costs.

FormCutter Plus:

Data:

Working area: 50 x 50 mm

Collimating focal length: 75, 100 mm, Focus lengths: 75, 100, 150 mm

Axial length: 560 mm (FF100)

Dimensions: 245 x 265 mm

Offline programming of the cutting contour by CAD CAM

The FormCutter Plus excels at creating complex 3D cuts in series production, offering high precision in cutting complex workpiece geometries. It is particularly suited for agile robot applications in the automotive industry, delivering top-quality cutting.

Advantages include complex 3D laser cutting, with the FormCutter Plus consisting of an X/Y-axis system and a cutting head with a Z-axis, typically attached to a robot arm. The robot positions the system and initiates the cutting process, guiding the cutting head through the programmed geometry to create a high-precision cutout. This cutting movement is far more precise and quicker than a robot alone could achieve. Common applications include laser cutting antenna holes and roof rail holes in vehicle bodies, as well as design-specific holes and recesses in truck production.

Simple, robust, and reliable, the FormCutter Plus is suitable for integration into complex production lines operating under demanding conditions. Its long service life, slim front design, and easily accessible media connections make it an attractive choice for integration into new or existing automated systems.

MiniCutter:

Data:

max. laser power: 2 kW (for wavelengths of 1030-1090 nm)

Collimating focal length: 75 mm, Focus lenghts: 75, 100, 125, 150 mm

NAmax: 0.13 at FC75

Dimensions: 50 x 50 x 258 mm (FF 75)

Weigths: 1.4 kg

Vertical adjustment range of focal position: ±4 mm

The MiniCutter is a versatile all-rounder for thin sheets, offering efficient 2D and 3D applications up to 2 kW. As a simple, compact plug-and-play solution, it delivers excellent cutting quality at an unbeatable price, allowing you to process sheet thicknesses up to 10mm with solid-state lasers.

Advantages include flexibility for different applications, with fast-reacting distance control ensuring consistently good and reproducible cutting quality for complex 3D metal parts. Its slim design provides high accessibility for machining strongly curved components. The focusing optics are beneficial not only in robot applications but also in laser cutting flat, thin metals worldwide.

User-friendly operation is another advantage, with easy-to-maintain features like quick, tool-free protective glass changes. The externally adjustable focus position allows for cutting process optimization. In summary, the MiniCutter offers a reliable, user-friendly solution at an attractive price.

Precitec Laser Nozzle

Precitec is a well-known company that specializes in manufacturing laser processing solutions, particularly in the areas of welding, cutting, and cladding. One of their products, the laser nozzle, is an essential component in laser cutting and welding applications.

The Precitec laser nozzle is designed to deliver a high-quality, focused laser beam to the material being processed. It also aids in the ejection of molten material and the cooling of the workpiece. These nozzles are designed to optimize the laser cutting or welding process, ensuring high precision, efficiency, and quality.

There are different types of Precitec laser nozzles for various applications, such as welding, cutting, or cladding. Each type has specific features tailored to the requirements of the process, including different nozzle geometries and materials to accommodate the desired laser power and focus.

Key features of Precitec laser nozzles include:

High precision: Precitec laser nozzles ensure accurate and consistent focusing of the laser beam, which is crucial for achieving the desired quality in cutting, welding, or cladding processes.

Durability: These nozzles are made from high-quality materials, such as copper or ceramics, to withstand high temperatures and wear during the laser processing.

Compatibility: Precitec offers a wide range of laser nozzles compatible with various laser processing heads and systems, making it easy for users to find the right nozzle for their specific application.

Customization: Precitec can also provide custom-made laser nozzles to cater to specific requirements or unique applications.

In conclusion, Precitec laser nozzles are essential components for laser processing applications, offering high precision and efficiency in various industrial settings. They are designed to provide a focused and powerful laser beam, ensuring optimal cutting, welding, and cladding results.

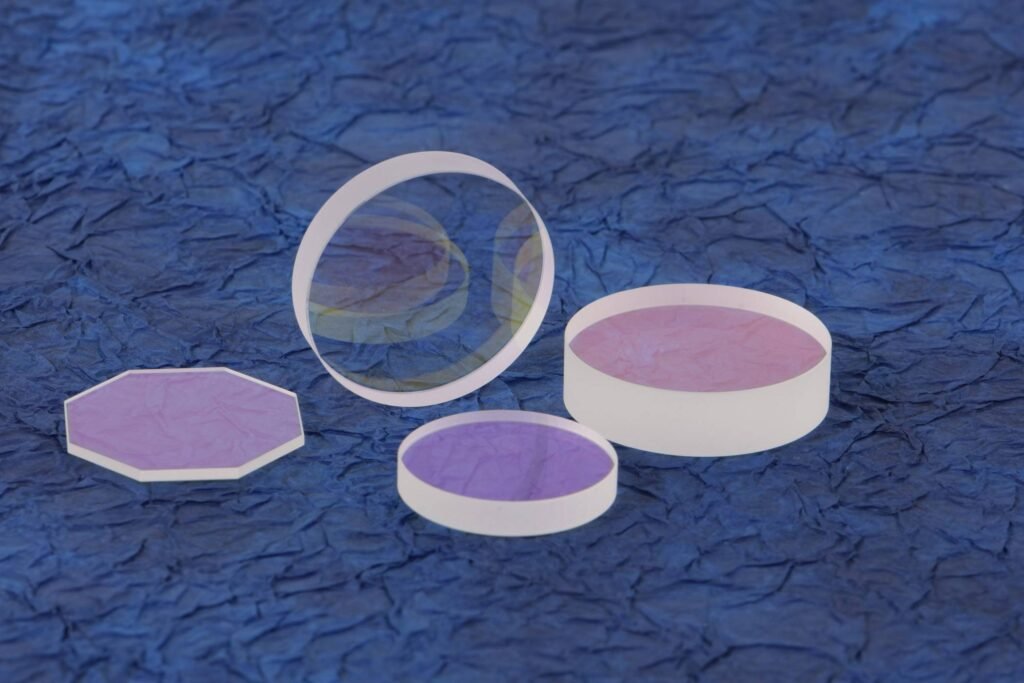

Precitec Laser Protectice Windows

Precitec Laser Protective Windows are another important component in the laser processing industry.

The primary function of Precitec Laser Protective Windows is to protect the laser processing head, particularly the focusing optics, from damage caused by debris or reflections. Additionally, they ensure the safety of operators working in the vicinity of the laser processing system.

Key features and benefits of Precitec Laser Protective Windows include:

High-quality materials: Precitec Laser Protective Windows are made from high-quality optical materials, such as quartz or fused silica, which provide excellent transmission properties and durability, ensuring a long service life.

Protective coatings: These windows often feature specialized coatings, such as anti-reflective or dielectric coatings, that minimize laser reflection and maximize laser transmission, ensuring optimal performance and protection for the laser head and focusing optics.

Wide compatibility: Precitec offers a range of Laser Protective Windows compatible with various laser processing heads and systems. This compatibility ensures that users can find the right protective window for their specific application.

Customization: Precitec can also provide custom-made Laser Protective Windows to meet specific requirements or unique applications.

Safety: By protecting the laser processing head and operators from harmful laser reflections and debris, Precitec Laser Protective Windows contribute to a safer working environment.

Precitec Laser Ceramic Part

Precitec Laser Ceramic Parts are essential components in laser processing applications, specifically in the areas of laser cutting, welding, and cladding. These high-performance ceramic components are designed to provide optimal performance, durability, and protection for the laser processing equipment.

Ceramic parts are utilized in various components of a laser processing system, including laser nozzles, protective windows, and other parts that may be exposed to high temperatures or require insulation. The use of ceramics in these applications offers several advantages due to their unique properties.

Key features and benefits of Precitec Laser Ceramic Parts include:

High temperature resistance: Ceramics can withstand extremely high temperatures, making them ideal for applications where intense heat is generated, such as laser processing. This property ensures the longevity and durability of the components in which they are used.

Thermal insulation: Ceramic materials are excellent thermal insulators, which helps protect sensitive components from excessive heat and temperature fluctuations during laser processing.

Electrical insulation: Ceramics are also excellent electrical insulators, which can be beneficial in certain applications where electrical conductivity could pose a risk.

Wear resistance: Ceramic materials are highly wear-resistant, ensuring that the components remain functional and effective even after extended use in harsh environments.

Request A Free Quote

Have any questions about laser parts?

Don’t hesitate to contact us. Lasersourcing’s product specialists are very happy to help you and provide a variety of flexible and reliable solutions to help you solve various problems.

Tel

+86-15370952128

lasersourcing@hotmail.com

15370952128

+86-15370952128