The Secrets of Plasma Cutting Gases

I. Introduction

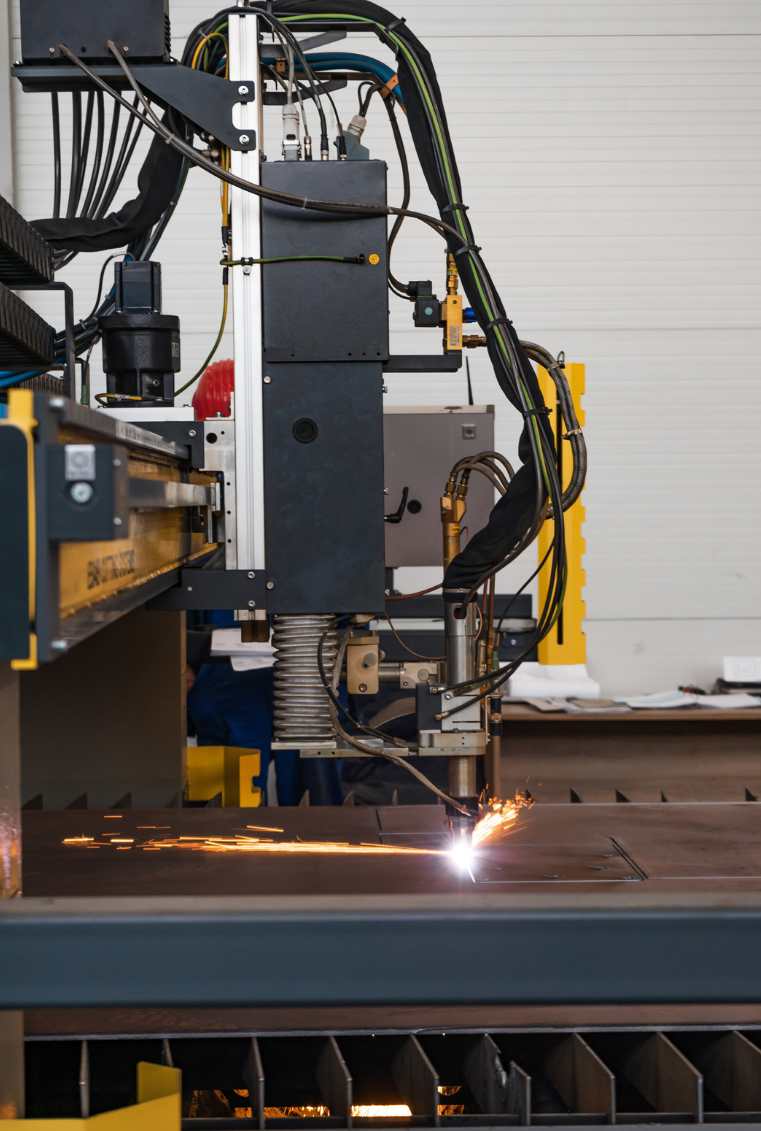

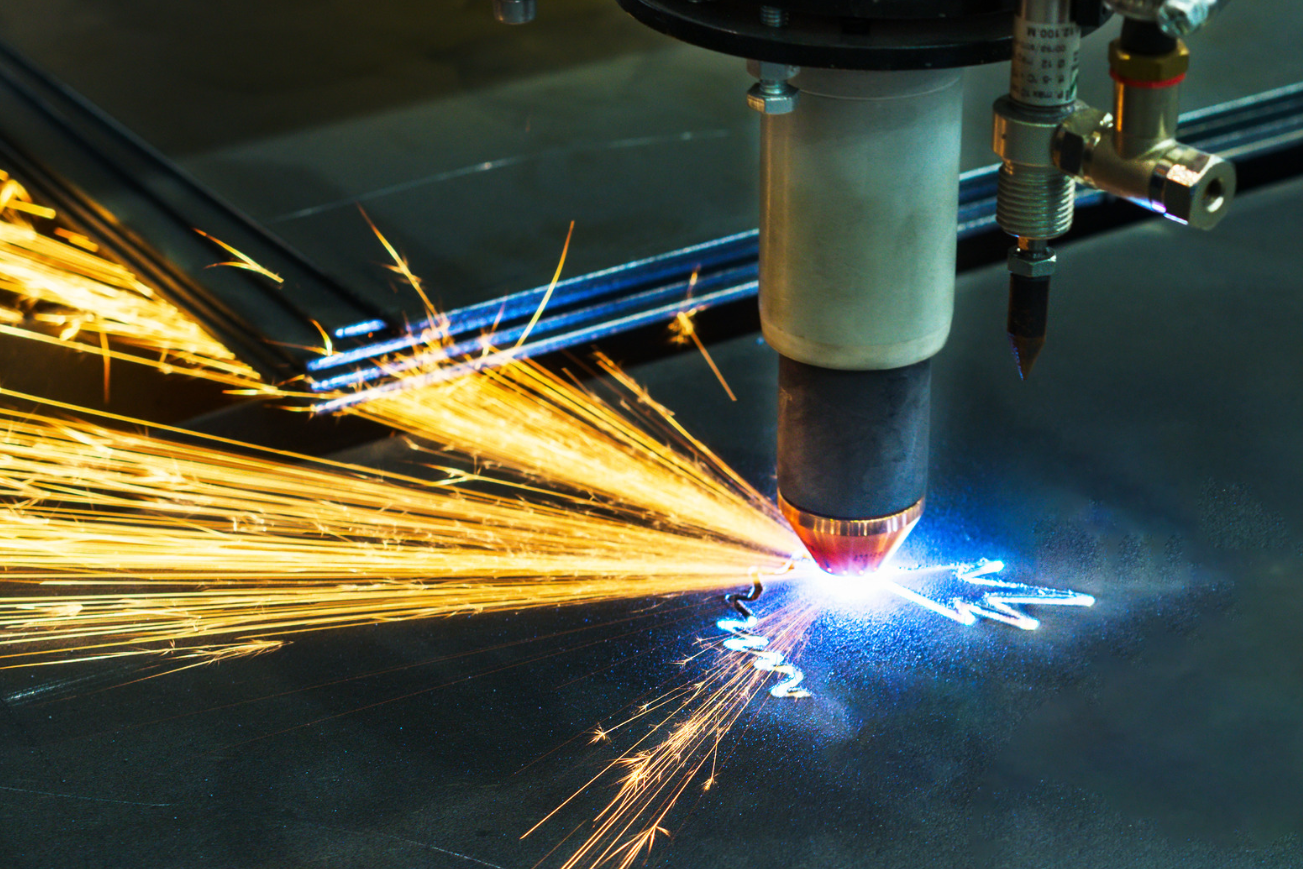

A. Brief overview of plasma cutting

Plasma cutting is an advanced metal fabrication process that utilizes a high-velocity jet of ionized gas to cut through materials. The gas, which is often a mixture of different elements, becomes electrically conductive when exposed to an electrical arc. This generates intense heat, which is focused by a nozzle to create a thermal reaction capable of melting and severing a wide range of metals and other materials. Plasma cutting technology is widely used across various industries such as manufacturing, automotive, shipbuilding, and aerospace due to its high precision, fast cutting speeds, and versatility in handling complex shapes and intricate designs.

B. Importance of plasma cutter gases

The role of plasma cutting gases is crucial in the success of the cutting process. These gases not only facilitate the formation of plasma but also impact the cutting quality, speed, and performance. The selection of the appropriate plasma cutting gas depends on the type of material being cut, as well as the desired cut quality and efficiency. Since different gases possess unique properties, they can significantly affect the cutting process, including the kerf width, edge smoothness, reduction of dross formation, and the precision of cuts. Additionally, certain gases may be more cost-effective or environmentally friendly, making them a better choice in specific circumstances. By understanding the functions and characteristics of various plasma cutting gases, fabricators can choose the most suitable gas for their specific applications and achieve the best possible results.

II. Different Types of Plasma Cutting Gases

A. Oxygen

Oxygen is a common cutting gas for plasma cutting systems and is especially effective for cutting materials like mild steel. When used in a plasma torch, oxygen facilitates an exothermic reaction with the metal being cut, which creates an oxide slag that helps to blow away the molten metal. This results in a clean and precise cut with minimal dross. However, oxygen is not ideal for cutting materials such as aluminum and stainless steel due to its reactivity, which can cause oxidation and affect cut quality.

B. Nitrogen

Nitrogen is often used as a plasma cutting gas for materials like aluminum, stainless steel, and other non-ferrous metals. It is an inert gas, meaning it will not react with the metal being cut, resulting in a clean cut with reduced oxidation. Nitrogen can produce a slightly wider kerf width compared to oxygen, but it maintains good cut quality and may provide better overall results for certain materials.

C. Argon

Argon is another inert gas used in plasma cutting, often in combination with other gases like hydrogen. This mixture is typically used for high-amperage cutting of especially thick metals and for working with materials that require an especially clean, oxide-free cut, such as titanium. The addition of hydrogen to argon can enhance cutting speed and improve the quality of the cut by reducing the heat-affected zone.

D. Hydrogen

Hydrogen is rarely used on its own as a plasma cutting gas but is commonly combined with other gases such as argon or nitrogen. When used in a mixture, hydrogen can increase the overall cutting speed and temperature while providing a reduction in the heat-affected zone. This makes it suitable for cutting thick materials and improving cut quality on various metals.

E. Compressed air

Compressed air is an economical and readily available option for plasma cutting gas. It is a mixture of approximately 78% nitrogen, 21% oxygen, and trace amounts of other gases. Compressed air works well for cutting a wide range of materials, including mild steel, aluminum, and stainless steel, although it may not provide the same level of cut quality as some more specialized gas options. It is ideal for applications where the balance of cost, availability, and cut quality is a priority.

F. Comparing efficiency and applications

The choice of plasma cutting gas depends on the specific requirements of the job, including materials, cut quality, and budget. For example, oxygen is ideal for cutting mild steel but is not well-suited for aluminum or stainless steel. Nitrogen, on the other hand, performs better with such metals and can maintain a clean cut with reduced oxidation. Argon and hydrogen mixtures are ideal for more demanding cuts in thick materials or when an oxide-free finish is required. Compressed air offers a cost-effective solution for a variety of applications but may not provide the highest level of cut quality in all cases. To achieve the best results, it is essential to carefully consider the properties of each gas and select the most appropriate option for the specific cutting task.

III. The Dual-Gas Process in Plasma Cutting

A. Definition and purpose

The dual-gas process in plasma cutting involves the use of two distinct gases in the cutting procedure, one serving as the plasma gas and the other as the shield gas. The plasma gas is responsible for creating the electric arc that generates the plasma, while the shield gas helps to control the plasma arc, protect the cut, and cool the consumable parts of the torch. This combination of gases allows for improved control over the cutting process and can yield better results in terms of cut quality, speed, and precision.

B. Common gas combinations

Several common gas combinations are used in the dual-gas process, depending on the types of materials being cut and the desired outcome. Some of the typical combinations include:

– Oxygen and air: A popular choice for cutting mild steel, with oxygen serving as the plasma gas and air as the shield gas, providing a clean and smooth cut.

– Nitrogen and nitrogen: Ideal for cutting non-ferrous metals like aluminum and stainless steel, providing a clean cut with minimal oxidation.

– Argon and hydrogen: This combination is often used for cutting thick materials and specialty metals like titanium, where a high-temperature plasma arc and clean, oxide-free cut are required.

These combinations may vary in terms of pressure, flow rate, and amperage settings depending on the material and equipment used, and the optimal mix should be determined according to specific cutting requirements.

C. Advantages of the dual-gas process

The use of dual-gas processes in plasma cutting offers several advantages over using a single gas for both plasma formation and shielding. Some of the benefits include:

– Improved cut quality: The combination of gases allows for better control over the plasma arc and the cutting environment, resulting in a cleaner, smoother cut with reduced dross and heat-affected zone.

– Increased cutting speed: The optimal gas combination can provide a more efficient plasma arc, allowing for faster cutting speeds and shorter processing times.

– Enhanced process control: The use of two distinct gases provides an opportunity to fine-tune the cutting procedure to suit specific materials and desired outcomes, ensuring the best possible results are achieved.

– Extended consumable life: Using a dedicated shield gas can help to cool and protect the consumable parts of the torch, ultimately prolonging their lifespan and reducing overall operating costs.

Overall, the dual-gas process enables more precise control over the plasma cutting procedure, leading to improved performance and results across various applications.

IV. Gas Hoses in Large Plasma Cutting Machines

A. Dual-gas process requirements

In large plasma cutting machines that utilize the dual-gas process, gas hoses play a crucial role in delivering the necessary gases for both plasma formation and shielding. These machines typically require two separate gas hoses – one for each of the plasma and shield gases. This configuration allows for the independent control of the gas flow rates, pressures, and mixtures, ensuring the optimal cutting performance based on the material being cut and the specific job requirements.

B. Gas delivery and control

The gas hoses in a large plasma cutting machine are connected to gas supply sources, such as cylinders or bulk gas supply systems, and are often integrated with pressure regulators, flow control valves, and gauges. These components work together to deliver the appropriate amount of gas at the required pressure to the cutting torch.

An essential aspect of gas delivery and control is maintaining the integrity of the gas hoses, as leaks can significantly impact cutting performance and safety. Gas hoses should be regularly inspected for signs of damage or wear and replaced when needed. Additionally, proper hose management, such as securing hoses away from cutting areas and avoiding sharp bends or kinks, can help prevent damage and prolong hose life.

Proper gas delivery and control are vital to ensuring the efficiency and effectiveness of the cutting process in large plasma cutting machines. By carefully managing gas hoses and related components, fabricators can achieve optimal cutting results and maintain a safe and efficient working environment.

V. Range of Suitable Gases for Plasma Arc Cutting

A. Selection criteria

When choosing the appropriate gas for plasma arc cutting, several factors need to be considered. These factors include the type of material being cut, the desired cut quality, the cutting speed, the thickness of the material, and cost considerations. It is essential to evaluate each of these criteria to select the gas or gas combination that best suits the cutting application. In some cases, more than one gas type may be suitable for a specific task, and the final choice will depend on factors such as gas availability, cost, and the specific requirements of the job.

B. Gas properties impacting cut quality

The properties of the selected cutting gas can significantly impact the overall cut quality. Factors such as the gas’s reactivity, thermal conductivity, and ionization potential can affect the formation of the plasma arc, the melting and removal of the material, and the resulting cut edge quality. For example, reactive gases like oxygen can lead to a more pronounced heat-affected zone and increased oxidation in certain materials, while inert gases like nitrogen or argon can provide a cleaner cut with less oxide formation. Additionally, certain gas mixtures can enhance the cutting performance, such as argon and hydrogen combinations, which improve the plasma arc’s temperature and cutting speed. Understanding how each gas type affects the cutting process is critical for achieving the best possible cut quality for a given application.

C. Environmental and safety considerations

The choice of plasma cutting gas should also take into consideration environmental and safety factors. Some gases may have higher greenhouse gas emissions, contribute to ozone layer depletion, or pose health risks if inhaled. Proper ventilation and air filtration systems are imperative to minimize exposure to harmful fumes and maintain a safe working environment. Additionally, safety precautions, such as the use of appropriate personal protective equipment and following proper cylinder handling and storage procedures, are essential to ensure the safe use of cutting gases in the workplace. When selecting the appropriate gas for plasma cutting, it is crucial to consider the environmental impact and the necessary safety measures that must be implemented to ensure a safe and efficient cutting process.

VI. History of Oxygen in Plasma Cutting

A. First use of oxygen as a cutting gas

The use of oxygen in cutting processes dates back to the early 20th century, with the development of oxy-fuel cutting techniques that combined pressurized oxygen with fuel gases like acetylene to generate a high-temperature flame. It was not until the 1950s and 1960s that the application of oxygen as a cutting gas in plasma cutting emerged, following the invention of the plasma arc cutting process. Early plasma cutting systems primarily used nitrogen as the cutting gas, but soon after, oxygen became a popular choice due to its superior cutting performance, particularly when cutting mild steel.

B. Evolution of oxygen gas technology in plasma cutting

Over time, oxygen gas technology in plasma cutting has evolved alongside the advancements in plasma cutting equipment and techniques. The development of more advanced plasma torches and power sources has allowed for better control over the oxygen flow, pressure, and the formation of the plasma arc. This has led to improved cutting performance, increased cutting speeds, and higher-quality results when using oxygen as the primary cutting gas.

Furthermore, the introduction of the dual-gas process, which often involves using oxygen as the plasma gas combined with a shielding gas, has further enhanced the effectiveness of oxygen-enhanced plasma cutting. This has resulted in even cleaner, more precise cuts, particularly in mild steel applications where the benefits of oxygen’s reactivity can be fully harnessed.

Continued advancements in plasma cutting technology are expected to further optimize the use of oxygen and other gases in cutting applications, enhancing efficiency, precision, and overall performance. As these improvements unfold, oxygen will likely maintain its position as a key player in the plasma cutting industry, providing a versatile, cost-effective, and reliable cutting gas option for numerous applications.

VII. Conclusion

A. Recap of the importance of plasma cutting gases

Plasma cutting gases play a critical role in the success of the plasma cutting process, influencing factors from creating the electric arc that generates plasma to determining the quality and precision of the cuts. The selection of the appropriate cutting gas or gas combination, such as oxygen, nitrogen, argon, hydrogen, and compressed air, is essential for achieving the desired results based on the material, cut quality, cutting speed, and overall efficiency. These gases are commonly used in most plasma cutters, including air plasma systems. Fabricators must understand the unique benefits, challenges, and applications of each gas to select the most suitable option for each cutting task.

B. The continuing evolution of plasma cutting technology

As plasma cutting technology advances, so too does our understanding of the role and importance of plasma cutting gases. Innovations in dual-gas processes, torch design, and power sources have led to the introduction of the best secondary gas options for improved cutting performance. These developments enhance the capability to fine-tune and optimize cutting gas parameters, such as the high-intensity plasma flame needed for carbon steel cutting.

With these innovations, the need for a thorough understanding of plasma cutting gases, like nitrogen plasma, and their impact on cutting processes will only grow. It is also essential to know how the plasma cutter gas transmits energy to the material being cut. By staying informed about cutting gas technologies and their applications, fabricators can maintain a competitive edge while producing high-quality, efficient, and precise cuts across various industries.

Contact Us

Have any questions about plasma parts?

Plasma cutting equipment Accessories Safety protection products, etc.

Tel

+86-15370952128

lasersourcing@hotmail.com

15370952128

+86-15370952128