Precitec Laser Cutting Head: A Comprehensive Guide to Understanding and Utilizing this Innovative Technology

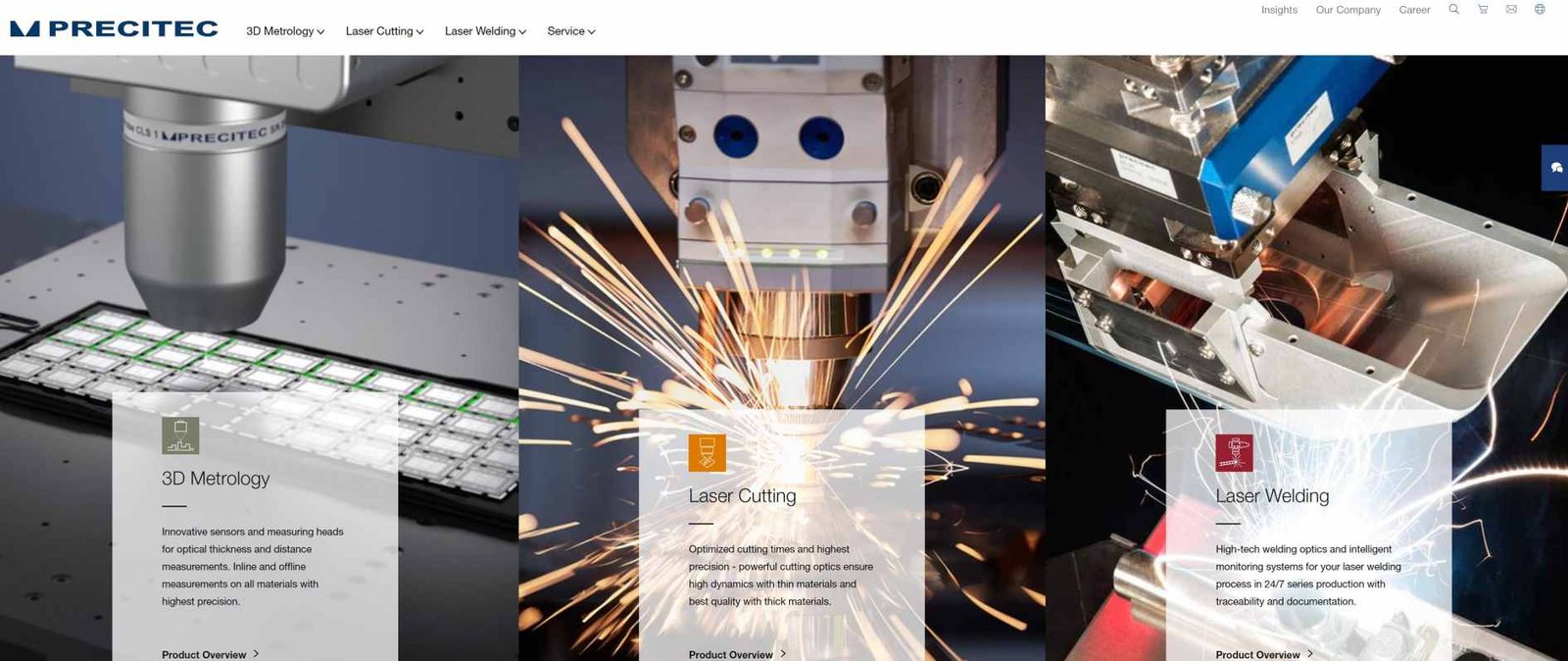

Introduction

Definition and explanation of laser cutting technology

Laser cutting is a precision manufacturing process that uses a highly focused laser beam to cut and shape materials. The laser beam is generated by a laser source, typically a gas laser or a solid-state laser, and directed onto the material to be cut by a set of mirrors or a lens. The intense heat from the laser beam melts, burns, or vaporizes the material, creating a clean and precise cut. This technology is widely used in industries such as automotive, aerospace, and medical device manufacturing.

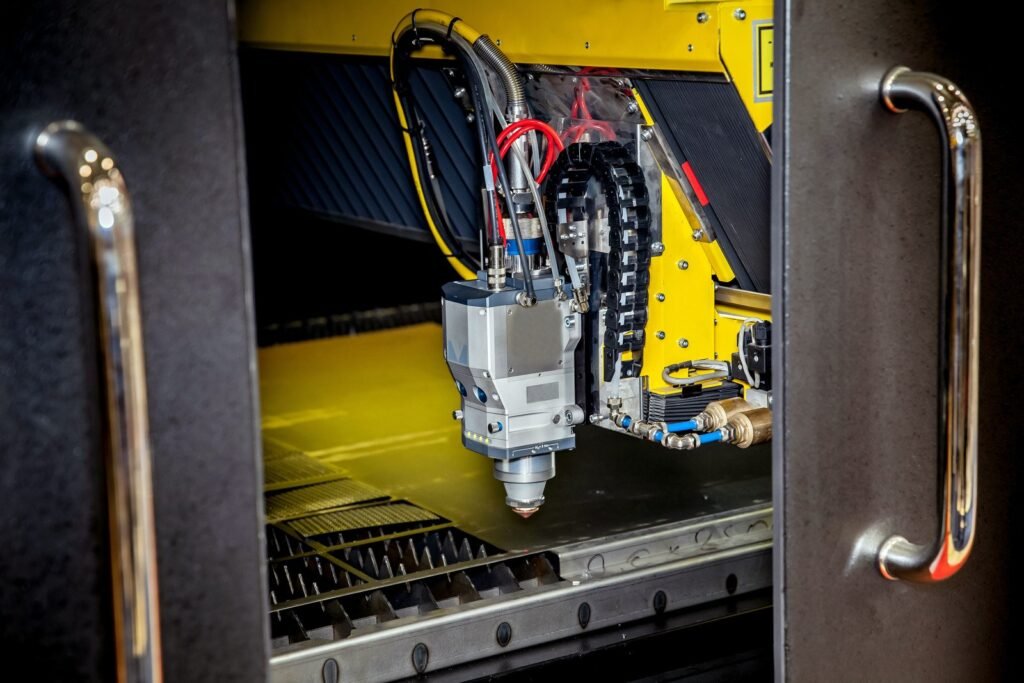

Overview of the Precitec laser cutting head(laser cutting process)

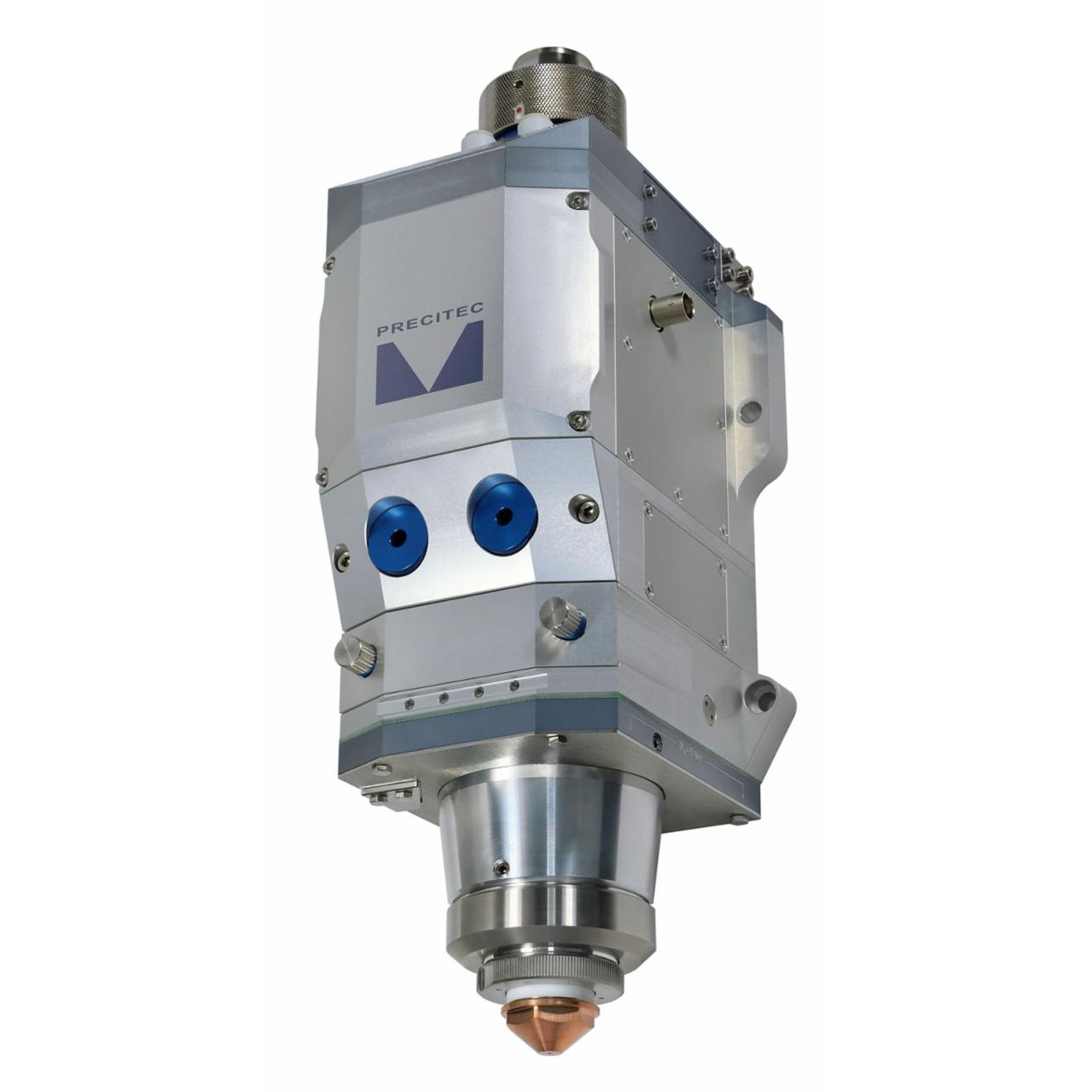

The Precitec laser cutting head is a high-performance cutting head designed for use with high-power laser sources. It is known for its precision, accuracy, and ability to cut a wide range of materials. The unique design of the cutting head allows for easy maintenance and replacement of parts, making it an economical choice for industries that require high precision cutting.

The Precitec laser cutting head is composed of several key components, including the laser resonator, the cutting head itself, and the control system. The laser resonator is the source of the laser beam, and it is typically a high-power CO2 or fiber laser. The cutting head is the part of the system that directs the laser beam onto the material to be cut. It is typically composed of a number of different optical components, including mirrors, lenses, and focus units, which work together to focus the laser beam onto the cutting point.

The control system is responsible for controlling the laser beam and the cutting head. This can be done through manual adjustment, CNC control, or software control, depending on the specific system.

Comparison with other laser cutting methods

One of the key advantages of the Precitec laser cutting head is its reliability and load capacity, which allows it to handle heavy workloads and maintain its precision and quality over time. Additionally, the Precitec laser cutting head is designed to handle very high laser power, which enables it to cut through thicker and harder materials with ease. The cutting nozzle design also plays a vital role in its precision and efficiency, it’s specifically designed to focus the laser beam to a small spot size for precise cuts and minimal heat affected zone. Compared to other laser cutting methods, the Precitec laser cutting head offers increased reliability, load capacity, high laser power, and precision cutting nozzle.

All of these features make it an ideal choice for industries that require high precision and quality of cuts, such as automotive, aerospace, and medical device manufacturing.

Technical specifications

Laser sources and power

The laser source is the device that generates the laser beam used in laser cutting. The most common types of laser sources used in laser cutting are CO2 lasers, fiber lasers, and Nd:YAG lasers. CO2 lasers use a mixture of carbon dioxide, nitrogen, and helium as the lasing medium, while fiber lasers use a doped fiber as the lasing medium. Nd:YAG lasers use a crystal of neodymium-doped yttrium aluminum garnet as the lasing medium. The power of the laser source determines the maximum thickness and material that can be cut.

Cutting speed and accuracy

Cutting speed refers to the rate at which the laser beam moves across the material being cut. This is measured in inches per minute or millimeters per minute. The cutting speed is affected by factors such as the power of the laser source, the material being cut, and the thickness of the material. Cutting accuracy refers to how precisely the laser beam cuts the material. This is measured in thousandths of an inch or micrometers.

The cutting accuracy is affected by factors such as the quality of the optics, the stability of the laser beam, and the precision of the motion control system.

Materials that can be cut

Laser cutting can be used to cut a wide range of materials including metal, plastic, wood, and fabric. Metals such as steel, stainless steel, and aluminum are common materials that can be cut using a laser. Plastics such as acrylic, polycarbonate, and PVC can also be cut using a laser. Wood and fabric can also be cut using a laser, but typically require lower power laser sources. The Precitec laser cutting head is particularly suitable for cutting more thickness and hard materials such as metal sheets, tubes and so on. It’s also effective in cutting more complex shape and designs in materials.

Precitec Laser Cutting's main products

Precitec offers a wide range of laser cutting heads, each with its own unique features and capabilities. We will list some of the best selling laser heads:

Advantages

obtain optimized cut qualities

One of the main advantages of Precitec laser cutting head is its high precision and quality of cuts. The laser beam can be focused to a very small spot size, which allows for cuts with tight tolerances and minimal heat affected zone. Additionally, laser cutting can produce very smooth edges, which is important for many industrial applications. The Precitec laser cutting head is known for its high precision and quality of cuts, which is why it is widely used in industries such as automotive, aerospace, and medical device manufacturing.

Low maintenance costs

Another advantage of the Precitec laser cutting head is its low maintenance costs. Laser cutting systems typically require little maintenance and have a long lifespan. The Precitec laser cutting head is designed with advanced optics and cooling systems to ensure optimal performance and longevity. Furthermore, the unique design of the cutting head allows for easy maintenance and replacement of parts. This makes it an economical choice for industries that require high precision cutting.

High efficiency and productivity(maximum and flexible performance)

Precitec laser cutting head technology is highly efficient and can increase productivity in many industries. The cutting head is continuously monitored to ensure precision and quality of cuts. With the integration of sensor technology, the cutting head is able to provide precise measurement and avoid production rejects. The Precitec laser cutting head is known for its fast cutting speeds, which can help increase productivity in industries such as automotive and aerospace. Additionally, the intelligent cutting solutions provided by the laser cutting head can reduce the need for additional finishing operations, further increasing efficiency. The laser cutting head can also integrate with existing data acquisition systems to streamline the cutting process.

Applications

Industries that commonly use Precitec laser cutting head

The Precitec laser cutting head is widely used in a variety of industries that require high precision cutting. Some of the most common industries that use this technology include:

Automotive: The Precitec laser cutting head is used to cut and shape metal parts for cars and trucks, such as body panels and engine components.

Aerospace: The Precitec laser cutting head is used to cut and shape metal parts for aircraft and spacecraft, such as fuselage and wing components.

Medical device manufacturing: The Precitec laser cutting head is used to cut and shape metal and plastic parts for medical devices, such as surgical instruments and implants.

Metal processing industry: The Precitec laser cutting head is used to cut metal sheets and tubes, often used in the production of metal products such as metal furniture, machines parts, and so on.

Real-world examples of products made using the technology

Automotive: body panels, engine components,

Aerospace: fuselage, wing components

Medical devices: surgical instruments, implants

Metal products: metal furniture, machines parts

Metal processing industry: metal sheets, tubes, etc. These are just a few examples of the many products that can be made using the Precitec laser cutting head. The technology is highly versatile and can be used to cut and shape a wide range of materials and products.

Precitec laser cutting head in the Automotive industry

Use in the production of body panels and engine components

The Precitec laser cutting head is widely used in the automotive industry to cut and shape metal parts for cars and trucks. One of the most common applications of this technology is the production of body panels and engine components. The high precision and quality of cuts provided by the Precitec laser cutting head allows for the creation of complex and precise shapes that are difficult to achieve with traditional cutting methods. This makes it an ideal choice for the automotive industry where precision and accuracy are critical.

Advantages over traditional cutting methods

Precitec laser cutting head offers several advantages over traditional cutting methods such as mechanical cutting or water jet cutting. For example, laser cutting is more precise, and produces less distortion and burrs. It also has a smaller heat affected zone and a smaller kerf width. Additionally, laser cutting can cut more complex shapes, and cut materials that traditional cutting methods can’t.

The high precision and quality of cuts provided by the Precitec laser cutting head can also help reduce the need for additional finishing operations, further increasing efficiency. Furthermore, the use of Precitec laser cutting head can also help to reduce the weight of the aircraft and improve fuel efficiency, which is particularly important in the aerospace industry.

Precitec laser cutting head in the Medical device manufacturing

Use in the production of surgical instruments and implants

The Precitec laser cutting head is widely used in the medical device manufacturing industry to cut and shape metal and plastic parts for medical devices such as surgical instruments and implants. The high precision and quality of cuts provided by the Precitec laser cutting head allows for the creation of complex and precise shapes that are difficult to achieve with traditional cutting methods. This makes it an ideal choice for the medical device manufacturing industry where precision and accuracy are critical.

Precitec laser cutting head in the Metal processing industry

Use in the production of metal sheets and tubes

The Precitec laser cutting head is widely used in the metal processing industry to cut and shape metal sheets and tubes. The high precision and quality of cuts provided by the Precitec laser cutting head allows for the creation of complex and precise shapes that are difficult to achieve with traditional cutting methods. This makes it an ideal choice for the metal processing industry where precision and accuracy are critical.

Advantages over traditional cutting methods

Precitec laser cutting head offers several advantages over traditional cutting methods such as mechanical cutting or water jet cutting. For example, laser cutting is more precise, and produces less distortion and burrs. It also has a smaller heat affected zone and a smaller kerf width.

Additionally, laser cutting can cut more complex shapes, and cut materials that traditional cutting methods can’t. The high precision and quality of cuts provided by the Precitec laser cutting head can also help reduce the need for additional finishing operations, further increasing efficiency. Furthermore, the use of Precitec laser cutting head in the metal processing industry can help to increase the productivity and reduce the production cost.

Conclusion

Summary of key points

Precitec laser cutting head is a high-performance cutting head designed for use with high-power laser sources. It is known for its precision, accuracy, and ability to cut a wide range of materials. It’s commonly used in various industries such as automotive, aerospace, medical device manufacturing, and metal processing industry.

The unique design of the cutting head allows for easy maintenance and replacement of parts, making it an economical choice for industries that require high precision cutting.

Future developments in laser cutting technology

The future of laser cutting technology is likely to involve the development of more powerful and energy-efficient laser sources, as well as the use of new materials and cutting methods. Additionally, advancements in software and automation are also expected to play a key role in the future of laser cutting, as they will enable more efficient and precise cutting operations.

The potential of Precitec laser cutting head in various industry

The Precitec laser cutting head has a lot of potential in various industries because of its high precision and quality of cuts, low maintenance costs, and high efficiency and productivity. Its potential to cut more complex shapes and more thickness and hard materials, makes it a versatile tool that can be used in many different applications.

Advantages of Precitec laser cutting head over other laser cutting methods

Precitec laser cutting head has several advantages over other laser cutting methods such as CO2 laser cutting and fiber laser cutting, for example, it’s capable of cutting thicker and harder materials than other methods, and it’s known for high precision and quality of cuts.

Additionally, Precitec laser cutting head typically requires less maintenance and has a longer lifespan than other methods.

Tips for choosing the right laser cutting head for your industry.

Consider the material you want to cut. Different laser cutting heads are designed to cut different types of materials, so it’s important to choose a laser cutting head that’s compatible with the material you’ll be cutting. For example, if you are cutting sheet metal, you will need a laser head designed for flat cutting, such as a Procutter, lightcutter, etc. If you are cutting tubing, then you will need a laser head designed for tube cutting, such as YK52; M1.5 KN, etc.

Assess your cutting needs. Consider the thickness and complexity of the material you want to cut, as well as the speed and accuracy of the cuts you want to make. These factors will help you determine the power and capability of the laser cutting head you need.

Consider maintenance and longevity. Some laser cutting heads require more frequent maintenance than others, so it’s important to consider the maintenance costs and longevity of your laser cutting head before you buy.

Compare different options and consult with an expert. There are many different laser cutting head options on the market, so it’s important to compare different options and consult with an expert to find the best fit for your industry.

Request A Free Quote

Have any questions about Raytools Laser Head

Don’t hesitate to contact us. Lasersourcing’s product specialists are very happy to help you and provide a variety of flexible and reliable solutions to help you solve various problems.

Tel

+86-15370952128

sales@lasersourcing.com

15370952128

+86-15370952128