Precitec Advanced Fiber Laser Head Manufacturer

I.Introduction

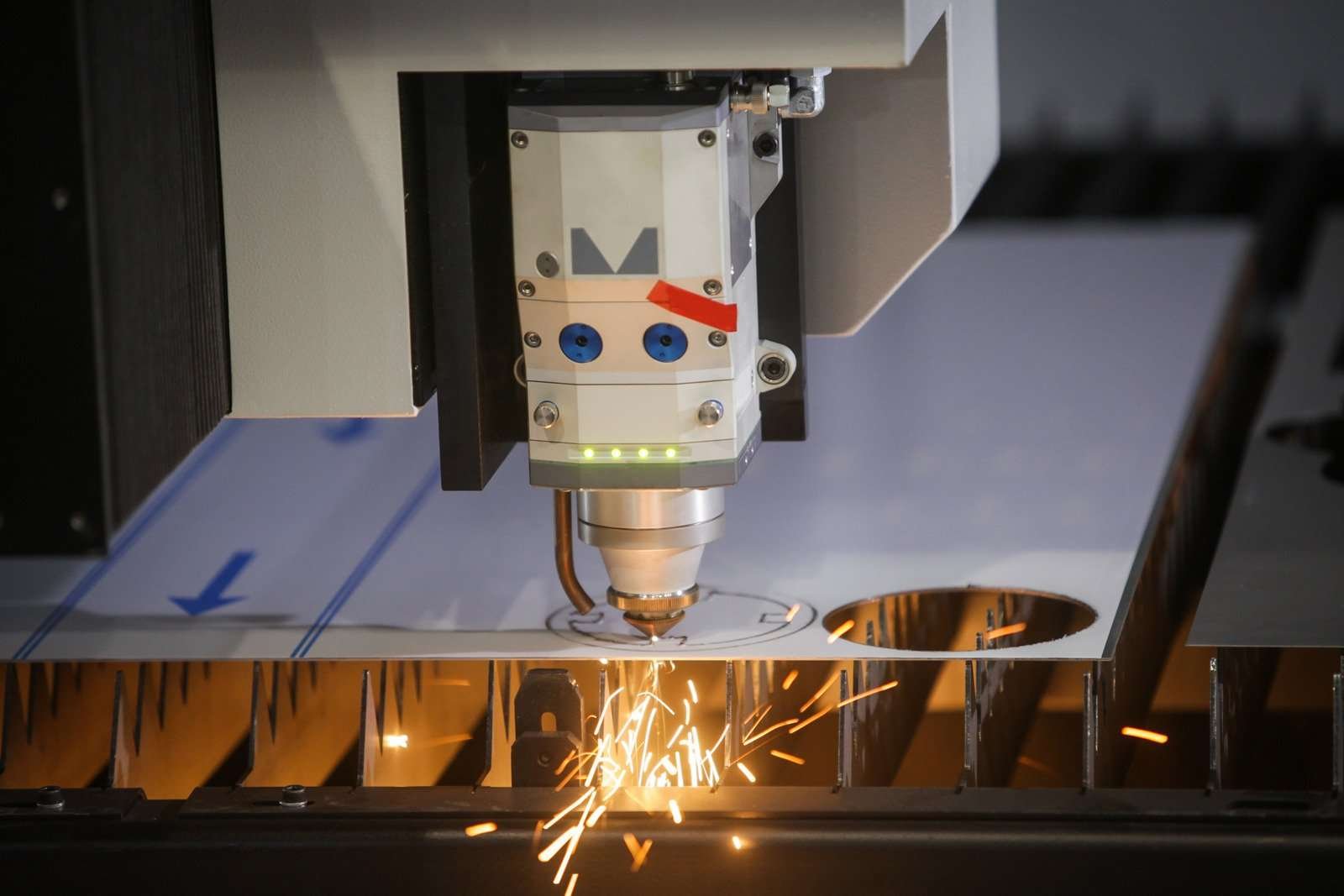

A. Definition of a Laser Head

A laser head is a crucial component of a laser cutting system that houses the laser beam and controls its direction and focus. The quality and performance of the laser head directly affect the accuracy, efficiency, and quality of the cutting process.

B. Importance of Precitec in the Fiber Laser Industry

Precitec is an advanced fiber laser head manufacturer that has been providing cutting-edge solutions for the laser cutting industry for over 25 years. Their innovative and high-quality laser heads are developed specifically to meet the demands of customers for high efficiency, high accuracy, and superior cutting quality. As a leading player in the industry, Precitec has gained a reputation for being a reliable and innovative partner for manufacturers around the world.

II. Precitec Company Overview

A. Company History

Precitec was founded in 1971 in Germany and has been a leading manufacturer of advanced laser cutting heads for the fiber laser industry ever since. They have over 50 years of experience in laser technology and are recognized globally for their high-quality products and innovative solutions.

B. Product Line

Precitec offers a wide range of laser cutting heads, including the Procutter, Procutter 2.0, Crocodile, YW52, and EG8030. These products are designed to deliver high accuracy and efficiency for a variety of cutting processes, making them suitable for use in various industries such as automotive, aerospace, and medical.

C. Ownership Details

Precitec is a privately owned company, with its headquarters located in Gaggenau, Germany. They have expanded globally with subsidiaries and distributors in Europe, Asia, and the Americas, including Precitec Korea and Precitec Precision Machineries Private Limited. The company is committed to providing cutting-edge technology to their customers, and they continue to invest in research and development to stay at the forefront of the fiber laser industry.

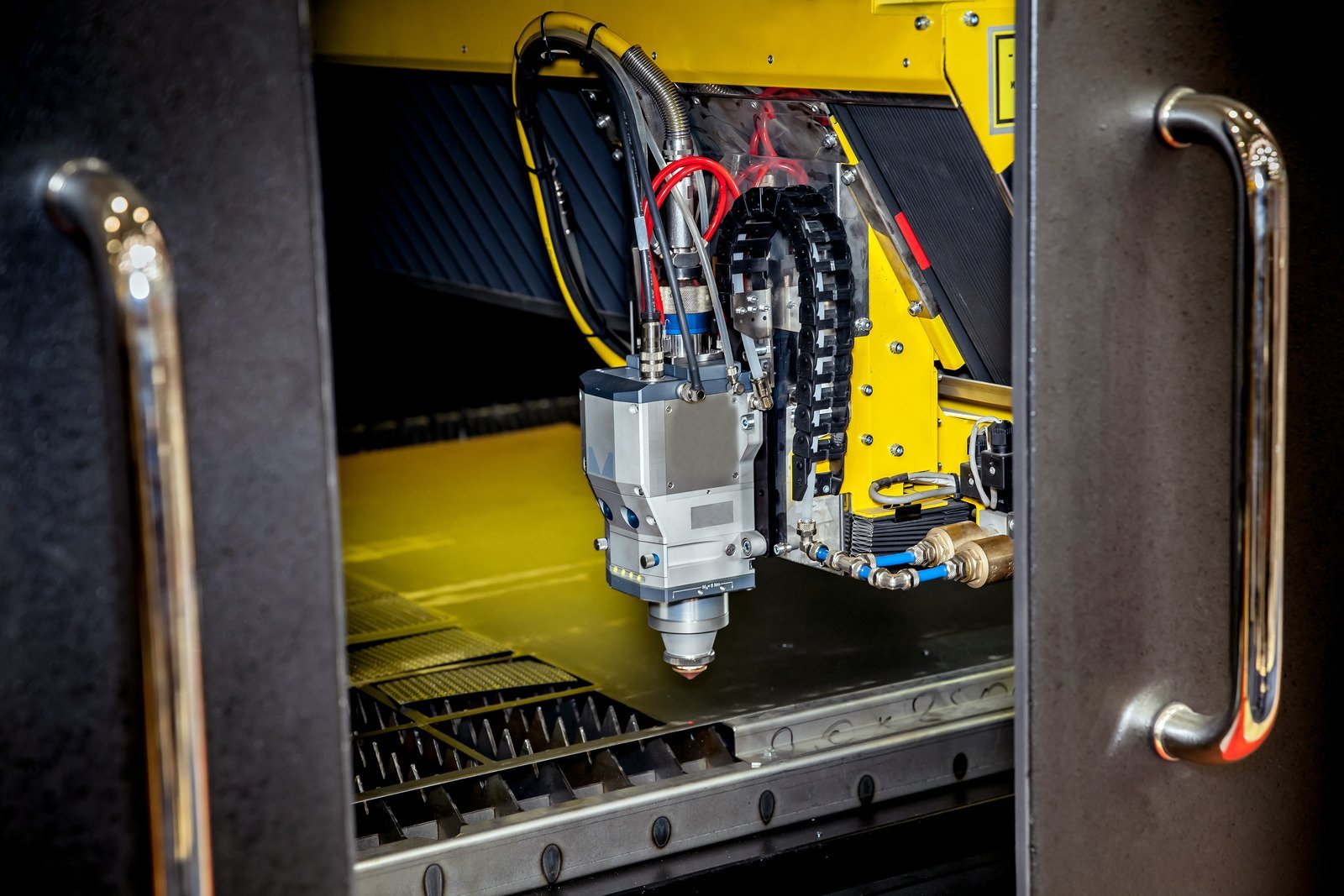

III. Precitec Laser Heads

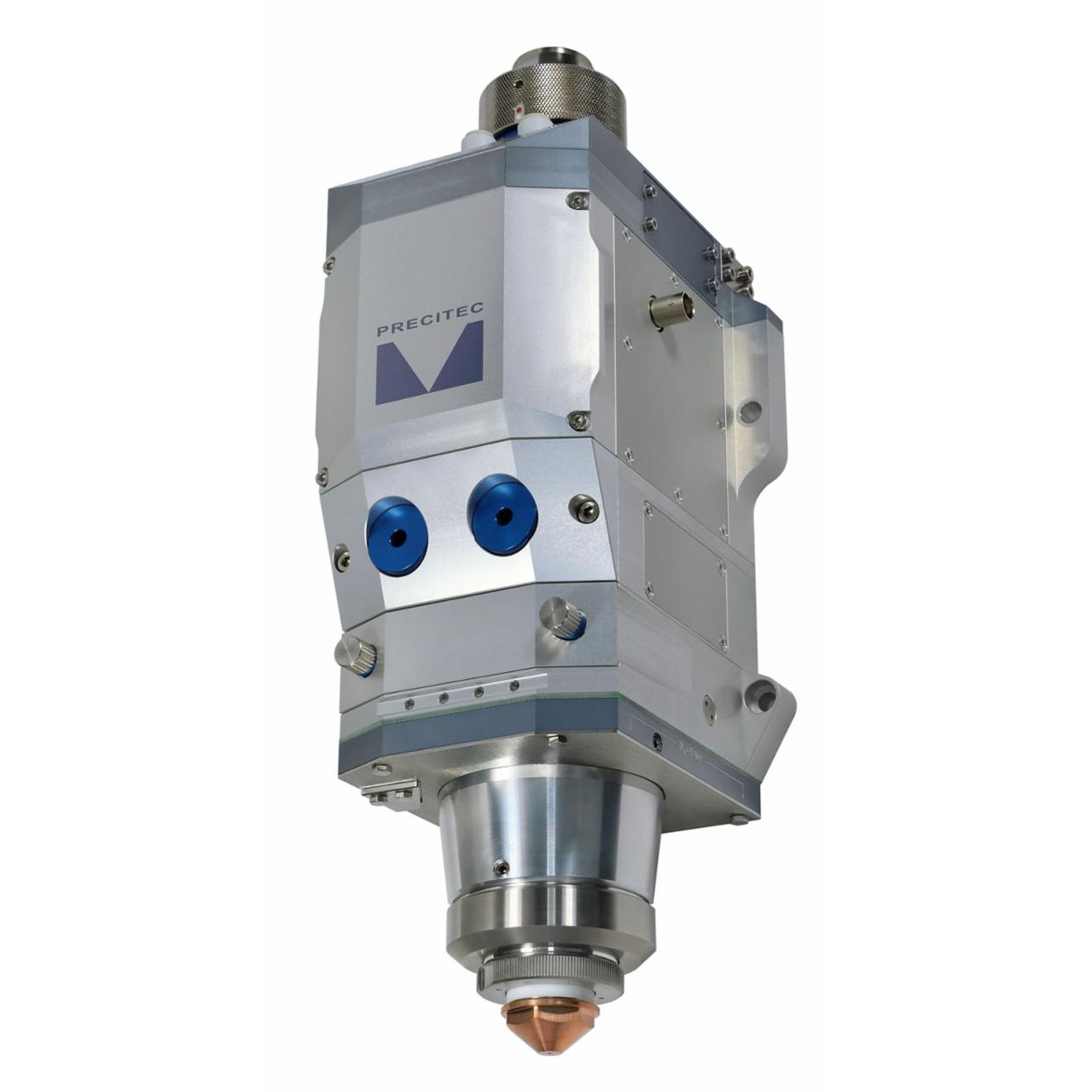

A. Overview of Precitec Laser Heads

Precitec is a leading manufacturer of advanced fiber laser heads that are designed for precision cutting, welding, and other industrial applications. Their laser heads are known for their high efficiency, accuracy, and reliability, making them a popular choice for customers around the world.

B. Features and Benefits of Precitec ProCutter

The Precitec ProCutter is a popular laser head model that is designed for high-speed and high-quality cutting of sheet metal. It features a lightweight and compact design, as well as a range of advanced features such as automatic focus adjustment, real-time power control, and a water-cooled lens. The ProCutter is known for its high cutting speeds, cutting quality, and long lifespan.

C. Features and Benefits of Precitec ProCutter 2.0

The Precitec ProCutter 2.0 is an updated version of the ProCutter that offers even greater cutting speed, accuracy, and quality. It features advanced technology such as a high-speed autofocus system, an automatic nozzle changer, and a real-time monitoring system that helps to optimize cutting performance. The ProCutter 2.0 is also designed to be more user-friendly and easier to maintain than previous models.

D. Features and Benefits of Precitec Crocodile

The Precitec Crocodile is a laser cutting head that is designed for cutting thick materials and for use in harsh industrial environments. It features a modular design that allows for easy customization and maintenance, as well as a range of advanced features such as automatic nozzle cleaning, real-time monitoring, and a range of safety features. The Crocodile is known for its high cutting speed, cutting quality, and durability.

E. Comparison with Competitor

Products Precitec faces competition from other manufacturers of laser heads, such as Trumpf and Amada. However, Precitec is known for its high-quality products, advanced technology, and focus on customer needs, which sets it apart from its competitors. Customers who choose Precitec can be assured of high-quality laser heads that are designed to meet their specific cutting needs.

IV. Precitec ProCutter 2.0

Precitec ProCutter 2.0 is an advanced fiber laser cutting head designed for high-precision cutting processes. It is a development of the previous ProCutter model, and it has several new features and benefits that make it an attractive choice for customers.

A. Overview and Features

The ProCutter 2.0 is designed with an integrated sensor system that measures the distance between the nozzle and the material being cut. This allows for real-time control of the focus position, resulting in high-quality cutting with excellent edge quality and minimal dross.

The head also features a modular design, making it easy to install and maintain. It has an automatic nozzle changer that allows for quick and easy switching between different nozzle sizes, reducing downtime and increasing productivity.

B. Cutting Capabilities and Applications

The ProCutter 2.0 can cut a variety of materials, including stainless steel, aluminum, and copper. It is particularly suitable for high-precision cutting applications, such as those in the automotive and aerospace industries.

The head has a maximum power output of 10 kW and a cutting speed of up to 100 m/min. This makes it an efficient and versatile tool for a range of cutting processes.

C. Comparison to Competitors

Compared to competitors in the fiber laser cutting head market, the ProCutter 2.0 has several unique features that set it apart. Its integrated sensor system, modular design, and automatic nozzle changer make it an attractive choice for customers looking for high-quality, efficient cutting solutions.

V. Frequently Asked Questions About Precitec Laser Heads

A. How does a laser head work?

A laser head works by focusing a laser beam through a lens within the cutting head and reducing it to an incredibly thin, concentrated beam. The beam is then directed at the material and can cut or engrave it ¹. The laser itself is generated by a laser resonator which emits a strong light beam that is reflected by a mirror system to the cutting head.

B. What is the price of a Precitec laser head?

The price of a Precitec laser head can vary depending on the model and specifications. For example, a Precitec ProCutter 2.0 laser head with 6kw, 8kw or 15kw power has a FOB reference price of $20,000.00 – $30,000.00 per piece.

C. What is the thickest metal a 1000W fiber laser can cut?

The maximum thickness a 1000W fiber laser can cut varies depending on the type of metal. For example, it can cut up to 10mm thick stainless steel, 8mm thick carbon steel, and 3mm thick aluminum alloy. The cutting speed also varies depending on the thickness of the material being cut.

D. What are Precitec's competitors in the fiber laser industry?

Precitec is a company that specializes in laser material processing and optical measurement technology. Some of its top competitors include Raloid Corp, Staub Machine Company Inc, Industrial Chrome Inc, CR Magnetics Inc and Vytek Laser Systems.

E. How many employees does Precitec have?

According to my sources, Precitec Optronik GmbH has 90 employees in Germany,Precitec currently has over 900 employees worldwide.

F. What is the difference between CO2 and fiber lasers?

The difference between CO2 lasers and fiber lasers is mainly in their wavelengths. Fiber lasers have a wavelength of 1030-1080 nm and can be quickly absorbed by metals, while CO2 lasers have a wavelength range of 10.6 μm. As a result, fiber lasers offer faster cutting speeds for metals, while CO2 lasers offer greater flexibility in material usage and can cut most metals and non-metals.

Overall, fiber lasers have several advantages over CO2 lasers, such as lower operating power costs, but they also have higher upfront costs such as equipment requirements, site requirements, and personnel quality requirements compared to equivalent CO2 lasers.

G. What does a laser head do?

A laser head is an essential component of a laser cutting machine that focuses the beam onto the material being cut. It also contains the nozzle and directs the flow of assist gas. The quality and precision of the laser head impact cutting quality. The head emits light and contains drive electronics and temperature stabilization circuits, as well as safety interlocks. Laser heads have various applications, including semiconductor lithography and flat panel applications with fast motion.

H. How much does a fiber laser cost?

The cost of a fiber laser varies depending on the specific model and features. It is recommended to contact a laser manufacturer or supplier for pricing information.

I. How much does a laser machine cost?

The cost of a fiber laser cutter can vary depending on its power and application. The average cost of fiber laser cutters in the market is around $39,800. A 1000W fiber laser cutting machine ranges from $30,000 to $80,000.

Fiber laser markers usually cost between $2,000 to $5,000. A set of fiber laser marking system will cost $2,950~$5,770 at 20W and $3,500~$6,400 at 30W.

The average cost of a handheld laser welder is around $7,900 depending on the fiber laser powers. A cheap portable laser welder with 1000W fiber laser source is priced from $5,500 for beginners with hobbyists in home use

J. What is the cutting quality of Precitec laser heads?

The cutting quality of Precitec laser heads is high due to their advanced engineering and technology. They are designed specifically for high efficiency and accuracy, producing precise cuts with minimal heat-affected zones. Precitec laser heads are also compatible with a wide range of machines and customizations to meet the specific needs of customers. Overall, the cutting quality of Precitec laser heads is highly regarded in the fiber laser industry.

VI. Conclusion

A. Summary of Key Points

In conclusion, Precitec is a leading manufacturer of advanced fiber laser heads, providing high-efficiency and high-accuracy cutting processes for customers worldwide. With a strong history and innovative product line, Precitec continues to push the boundaries of fiber laser technology.

B. Precitec's Impact on the Fiber Laser Industry

Precitec has made significant contributions to the fiber laser industry through the development of cutting-edge laser head technology. Their products have improved cutting quality and production efficiency, providing customers with reliable and cost-effective solutions.

C. Final Thoughts and Recommendations

As a supplier of Precitec consumables, we highly recommend using genuine Precitec products to ensure optimal performance and longevity of your fiber laser machine. With Precitec’s commitment to quality and innovation, you can trust their products to deliver exceptional cutting results.