Raytools Auto focus laser cutting machine supplier

Raytools is a manufacturer of laser heads and laser beam sources for industrial processing, 3D printing, and laser display applications. Their laser heads are known for their high quality and performance, and are used in a variety of industries including automotive, aerospace, medical, and electronics.

raytools laser Head Application

Flat Cutting

Raytools laser heads can be used for flat cutting applications, where a laser beam is used to cut through a material along a flat plane. This can be used to cut sheets of metal, plastic, or other materials into specific shapes or sizes. The laser head is typically mounted on a machine or robot, and the material is moved under the laser beam to make the cut. The quality and precision of the cut will depend on factors such as the power and focus of the laser beam, the material being cut, and the speed and accuracy of the cutting process. Raytools laser heads are known for their high quality and performance, and can be used to produce precise, efficient cuts in a variety of materials.

BM06K

Power rating 6KW; Standard auto focus laser cutting.

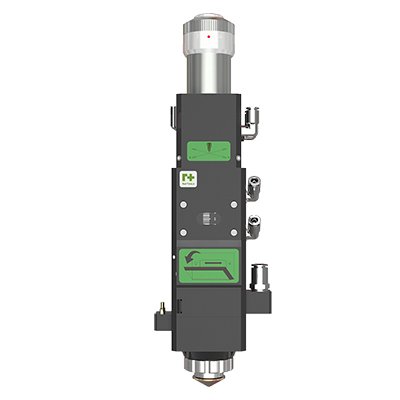

BM109

Power rating 1.5KW; Standard auto focus laser cutting.

BM111

Power rating 3.3KW; Standard auto focus laser cutting.

BM111E

Power rating 3.3KW; Smart sensor technology with real-time status monitoring; EtherCAT protocol.

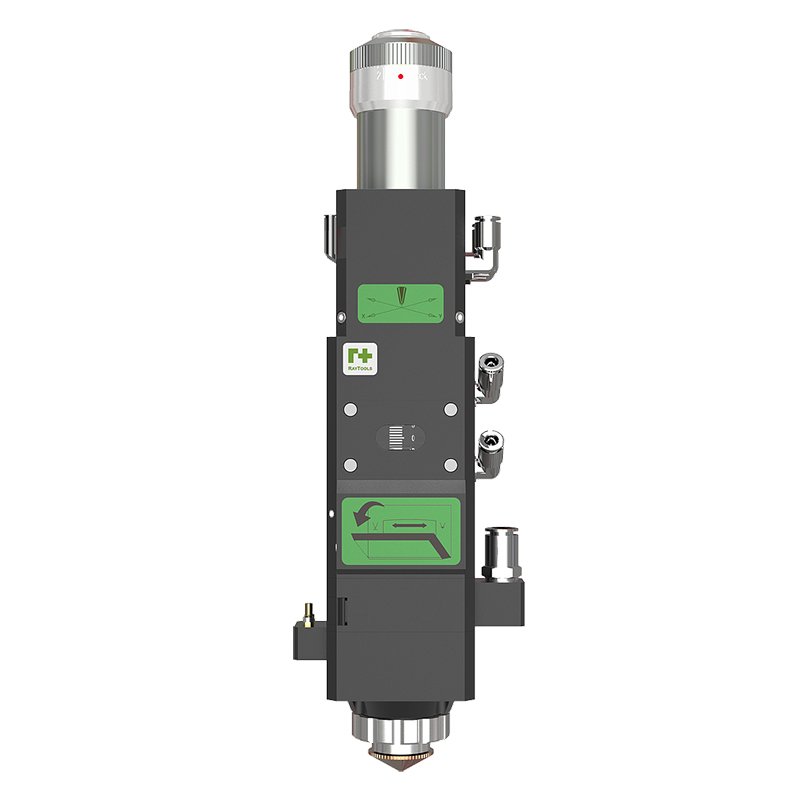

BM114

Power rating 6KW; Standard auto focus laser cutting.

BM114E

Power rating 6KW; Standard auto focus laser cutting.

BM115

Power rating 6KW/8KW/12KW; Updated from BM115 2.0; Standard auto focus laser cutting with capability for full power cutting.

BM115

Power rating 6KW/8KW/12KW; Smart sensor technology with real-time status monitoring; EtherCAT protocol.

BS04K

Power rating 4KW; Fully smart sensor technology with real-time status monitoring by APP or CNC. Auto focus by 0-10V or EtherCAT.

BS08K

Power rating 8KW; Fully smart sensor technology with real-time status monitoring by APP or CNC. Auto focus by 0-10V or EtherCAT.

BS12K

Power rating 12KW; Fully smart sensor technology with real-time status monitoring by APP or CNC; Auto focus by 0-10V or EtherCAT.

BT240S

Power rating 3.3KW; Standard manual focus laser cutting.

Robot Cutting

Raytools laser heads can also be used for robot cutting, which is a process of using a robotic arm equipped with a laser head to cut materials. This type of cutting offers a high level of precision and repeatability, and can be used to cut a variety of materials including metals, plastics, and composites. The laser head is mounted on the end of the robotic arm and is able to move freely in three-dimensional space, allowing it to access a wide range of cutting locations. Robot cutting is often used in manufacturing environments where large volumes of parts need to be cut quickly and accurately, and can be more efficient and cost-effective than manual cutting methods.

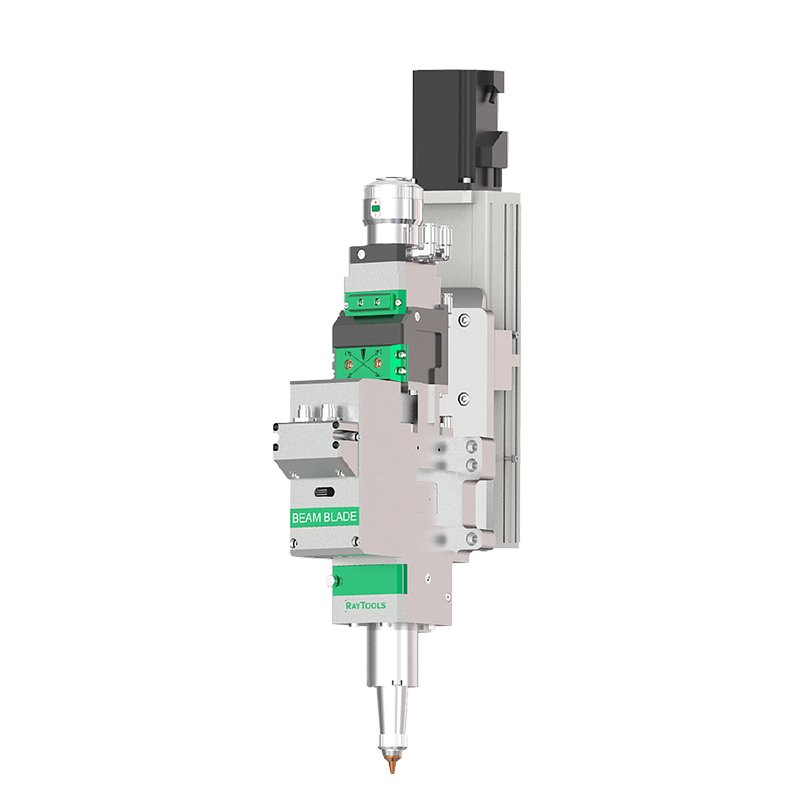

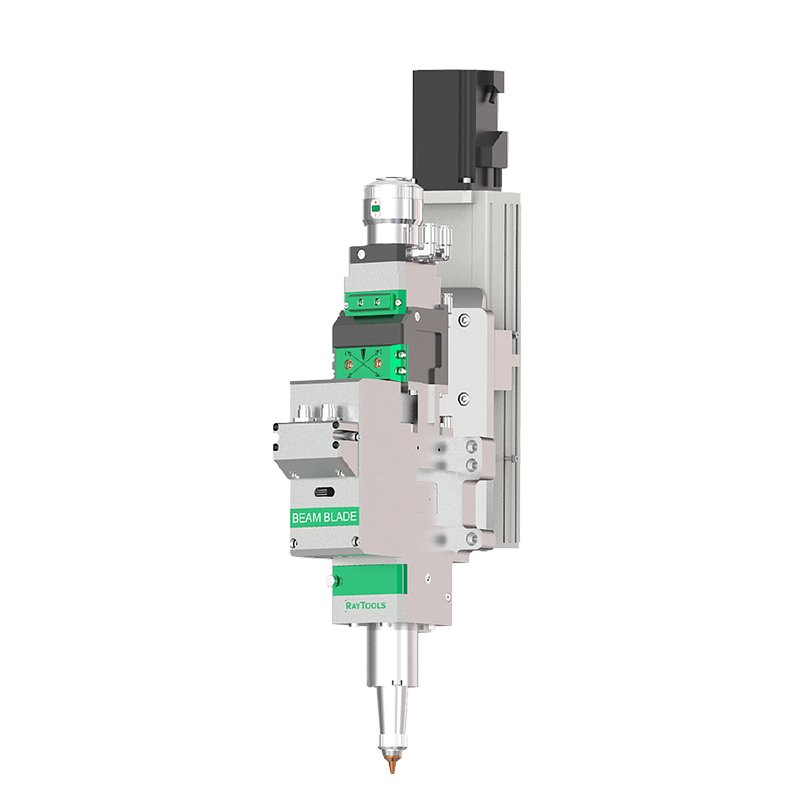

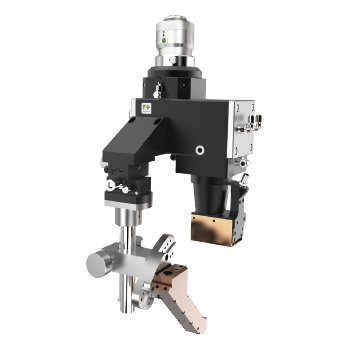

BD04K/BD08K+Motorized Slide Robotic Laser Cutting Head with External Z Axis

Power rating 4KW; Light-duty robot cutting along with external motorized slide and BMQ control cabinet.

BT220RC+Motorized Slide Robotic Laser Cutting Head with External Z Axis

Power rating 1.5KW; Light-duty robot cutting along with external motorized slide and BMQ control cabinet.

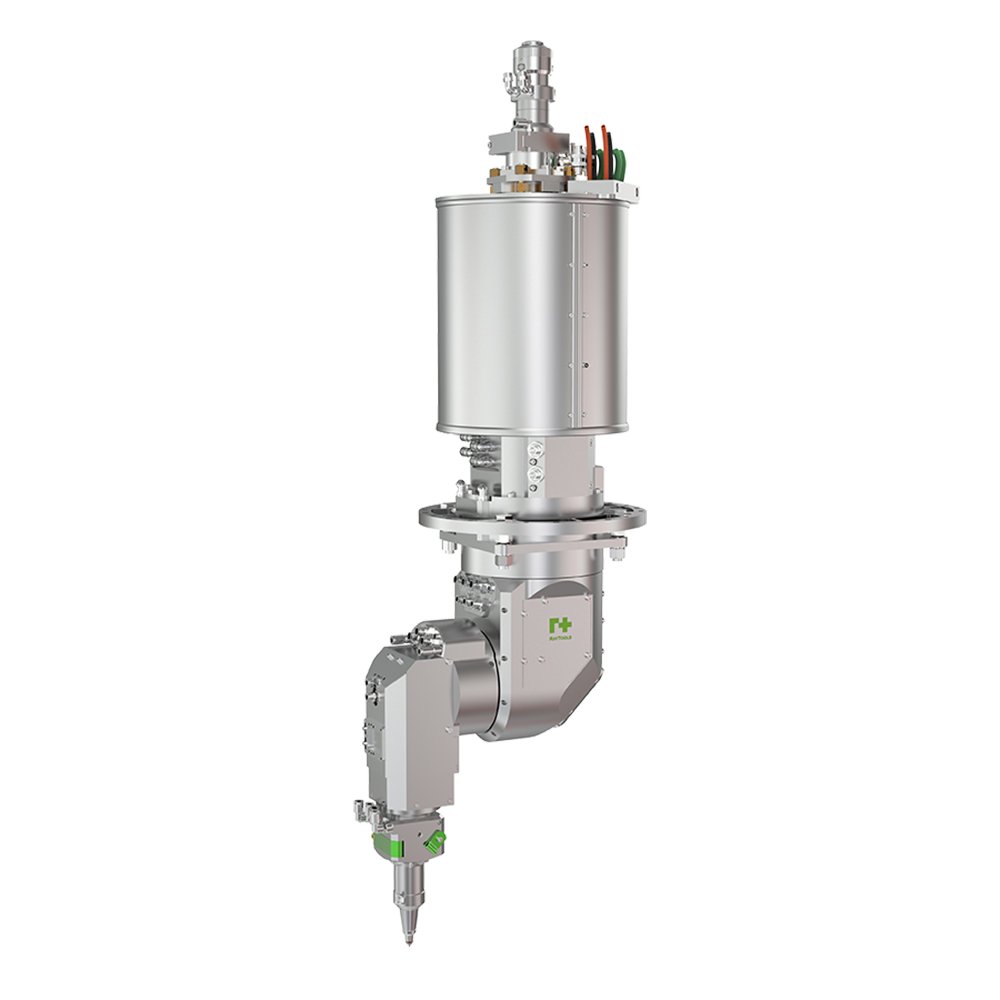

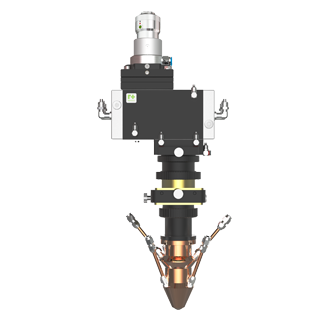

GF101 All-In-One Robotic Laser Cutting Head with Built-in Z Axis

Power rating 4KW; All-In-One design with built-in Z axis for robot cutting.

GF101+GF102 Robotic Laser Cutting Head with Built-in Z Axis and A/B Axis

Power rating 4KW; Robot cutting system with capacity to cut small contours.

Tube Cutting

Raytools laser heads can be used for tube cutting, which is a process of cutting tubes and pipes into specific lengths or shapes using a laser beam. This is typically done using a CO2 laser, which is able to cut through a wide range of materials including metals, plastics, and composites. The laser head is mounted on a cutting machine and focused onto the tube to be cut, producing a precise and clean cut with minimal heat affected zone. Tube cutting is widely used in the manufacturing industry for a variety of applications, including the production of parts and components, tubing for fluid handling systems, and decorative items.

BD04K/BD08K

Power rating 4KW/8KW,Standard auto focus tube cutting.

BM109TC

Power rating 1.5KW; Standard auto focus tube cutting.

BM111TC

Power rating 3.3KW; Standard auto focus tube cutting.

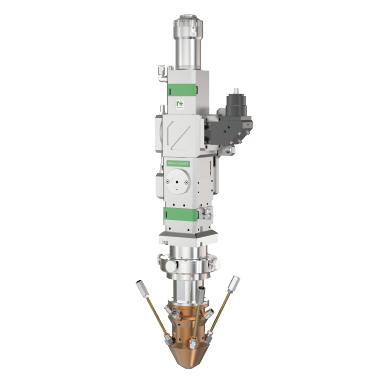

GF402 4-Axis

Power rating 6KW. Bevel laser cutting for tube. Fully built-in optics system.

Micro Cutting

Raytools laser heads can be used for micro cutting, which is a process of cutting very small and precise features into materials using a laser beam. This is typically done using a CO2 laser, which is able to produce a high-quality and precise cut with minimal heat affected zone. The laser head is mounted on a cutting machine and focused onto the material to be cut, producing features with dimensions in the micrometer range. Micro cutting is often used in the manufacturing of microelectromechanical systems (MEMS), medical devices, and other products that require extremely small and precise features. It can be more precise and efficient than other methods of micro machining, such as micro milling or micro EDM.

FM220 High Precision Micro Laser Cutting Head

Power rating 2000W; Ultra micro laser cutting in ceramic, medical and semi-conductor industry, etc.

5-Axis 3D Cutting

5-axis 3D cutting, which is a process of cutting three-dimensional shapes into materials using a laser beam and a machine with five axes of motion. This allows the laser head to access a wide range of cutting locations, enabling the creation of complex 3D shapes with a high level of precision. The laser head is mounted on the 5-axis cutting machine and focused onto the material to be cut, producing a precise and clean cut with minimal heat affected zone. 5-axis 3D cutting is widely used in the manufacturing industry for a variety of applications, including the production of parts and components, prototyping, and tooling. It can be more efficient and cost-effective than other methods of 3D cutting, such as 3D milling or 3D printing.

GF501 5-Axis 3D Laser Cutting Head

Power rating 4KW. 5-axis 3D laser cutting with fully built-in optics system.

Welding

The RayTools welding head is designed to be mounted on a robotic arm or other mechanical platform and used to perform precise laser welding on a variety of materials. The head is equipped with a laser beam delivery system and a range of optics and sensors to ensure accurate and consistent welding results. It is often used in manufacturing and fabrication settings where high-quality welding is required.

AK090 Laser Welding Head

Power rating 6KW; High power laser welding with mini size; Parabolic optics system.

BF320 Coaxial Wobble Laser Welding Head

Power rating 3KW. Wobble welding feature by galvo system. Built-in galvo and drive system.

BF330-2C/6C Scan Laser Welding Head

Power rating 2KW/6KW. Scan welding feature by galvo system with F-theta.

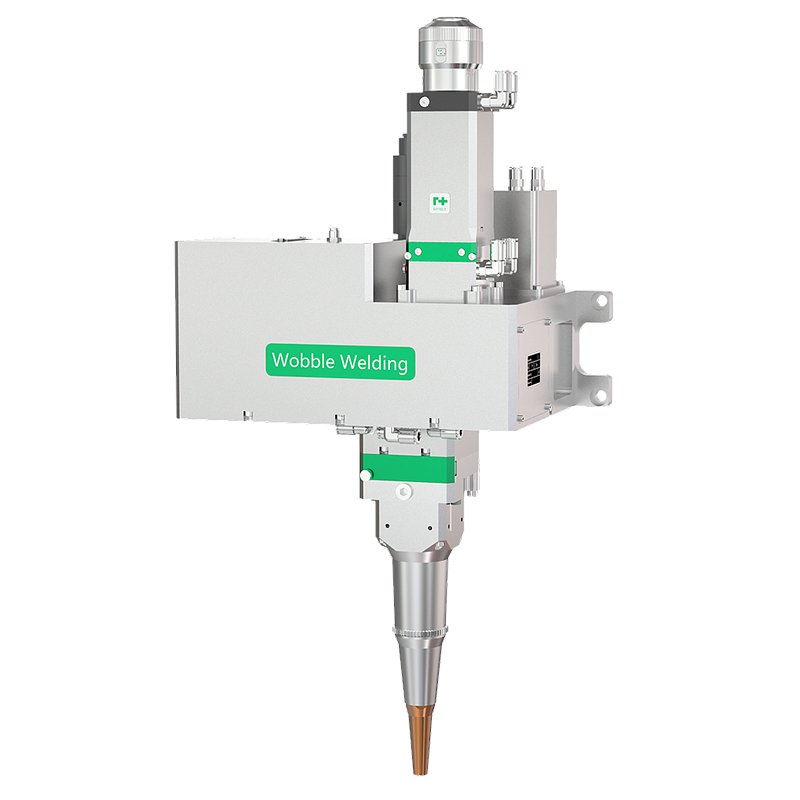

BF330-2F Wobble Laser Welding Head

Power rating 2KW. Wobble welding feature by galvo system. Built-in galvo and drive system.

BF330-4F Wobble Laser Welding Head

Power rating 4KW. Wobble welding feature by galvo system. Built-in galvo and drive system.

BF330-6F Wobble Laser Welding Head

Power rating 6KW. Wobble welding feature by galvo system. Built-in galvo and drive system.

BW101-GS 4-in-One Handheld Laser Processing Head

4-in-One Handheld Laser Processing Head, power rating 2kw, welding/cutting/weld seam cleaning/remote cleaning

BW210 Laser Welding Head

Power rating 2KW; Low power laser welding; Fiber/Diode/Blue version to match fiber laser, direct diode laser or blue laser.

BW240 Laser Welding Head

Power rating 4KW; Medium power laser welding;

BW290-6B Laser Welding Head

Power rating 6KW; High power laser welding. Hybrid version of wobble welding by fiber laser and fixed spot welding by 450nm blue laser.

BW290-6D Laser Welding Head

Power rating 6KW; High power laser welding. Hybrid version of fixed spot welding by fiber laser and diode laser.

BW290-8W Laser Welding Head

Power rating 8KW; High power laser welding. Broad-wavelength optics system compatible to diode or fiber laser.

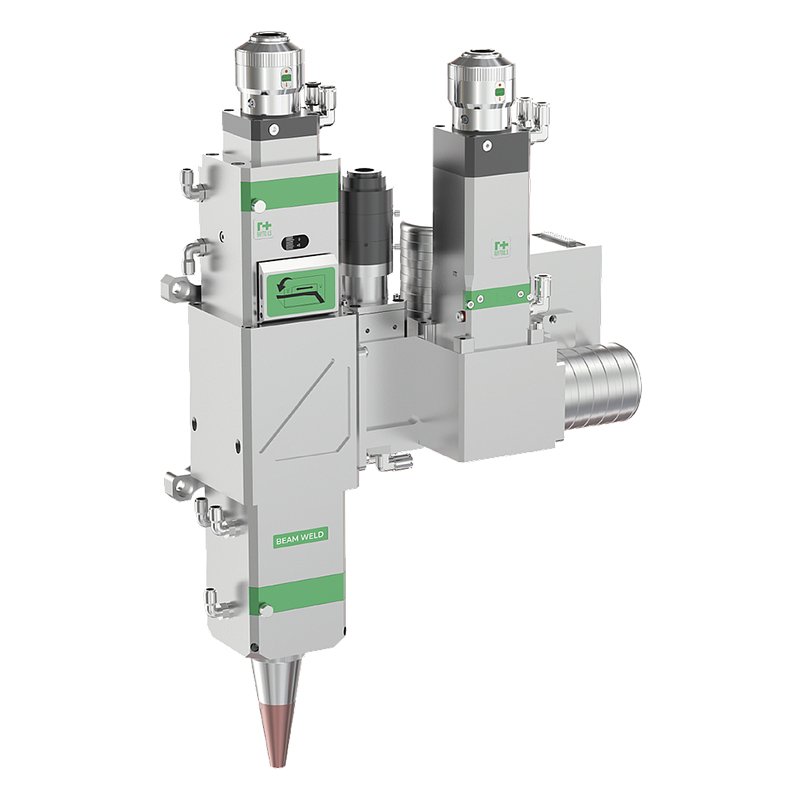

BW310 Dual-spot Laser Welding Head

Power rating 4KW; Dual-spot welding particulary for butt-welding of unequal thickness, different materials and galvanized steel.

Cladding & Hardening

RayTools Cladding & Hardening is a process in which a layer of material is deposited onto the surface of a workpiece using a laser beam. This process is often used to improve the surface properties of the workpiece, such as wear resistance, corrosion resistance, or thermal stability. It can also be used to repair damaged surfaces or to add functional layers, such as coatings for improved tribological performance or electrical conductivity. The material for the cladding layer can be in the form of a powder, wire, or paste, and is typically deposited using a laser beam with a high power density to melt and fuse it onto the surface of the workpiece.

AK190TC Laser Cladding Head

Power rating 6KW; 3-Way powder cladding; Parabolic optics system.

AK390HT Laser Hardening Head

Power rating 20KW; Laser hardening by rectangular beam spot; Parabolic optics system.

AK390PC Wideband Laser Cladding Head

Power rating 20KW; Wideband powder cladding; Parabolic optics system.

AK390TC Laser Cladding Head

Power rating 20KW; 3-Way powder cladding; Parabolic optics system.

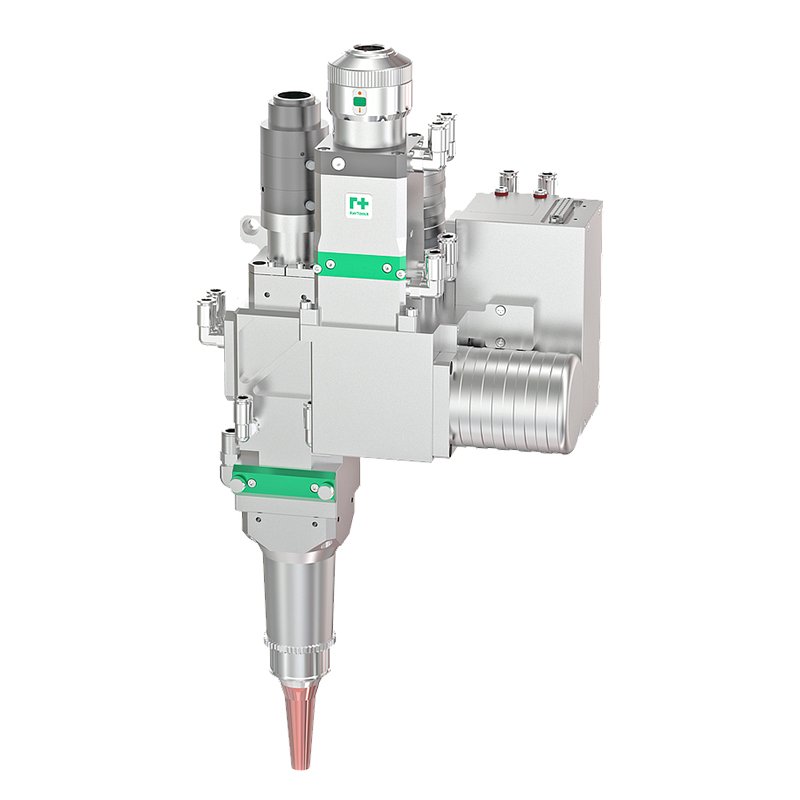

BC104 Laser Cladding Head

Power rating 4KW; 3-Way/4-way/annular powder cladding; Transmission optics system.

BC106 High Power Laser Cladding Head

Power rating 6KW; 3-Way/4-way/annular powder cladding; Transmission optics system.

IC104 Inner Tube Laser Cladding Head

Power rating 4KW; Ajustable spot size.

VB106 Multifuctional Laser Processing Head

Power rating 6KW; automatic switching between circular and rectangular spots

Still not finding what you're looking for? Contact our consultants for more available products.

Why Choose Raytools Laser Head From Lasersourcing ?

High quality products

Yes, the raytools laser heads offered by Lasersourcing are all original products with guaranteed quality and performance. If customers have any questions about the product, they can always contact Lasersourcing's customer service for assistance.

Fast delivery

For different orders, Lasersourcing will use the most suitable shipping method according to the customer's needs and the characteristics of the product to ensure that the product can be delivered to the customer as soon as possible. We usually use a variety of shipping methods such as sea, air, land and express (e.g. DHL, FEDEX, EMS, UPS, etc.). We will communicate with our customers after order confirmation and arrange shipping for them as soon as possible. Our goal is to meet our customers' needs in the shortest possible time and provide the best quality service to our customers.

Comprehensive after-sales service

We provide comprehensive after-sales service, including maintenance, replacement parts, technical support, etc.

Preferential price

We are able to provide you with preferential price, so that your purchasing cost is lower.

Professional sales team

We have a professional sales team who can help you understand the products and provide professional advice and assistance.

Frequently Asked Questions

● General

Stocked model 1pcs above

If you have custom requirements, you need to communicate separately to determine

● Product

Yes, the Raytools laser head we offer are all original and brand new, factory direct, quality guaranteed

● Payment

Payment less than 10000USD, 100% in advance. Payment more than 8000USD, 40% T/T in advance ,balance before shipment.

If you have another question, please feel free to contact us.

● Shipping

a. For small trial orders, by air or express: FEDEX, DHL, UPS, TNT, EMS, GATI, etc.

b. For large orders, we arrange sea or air freight according to your requirements.

Meet Us

At Lasersourcing, we believe that there is a better laser fitting solution for every customer. We are passionate about this and our mission is to manufacture and supply a range of laser machine parts products, backed by global service support, thus guaranteeing zero defects in the shortest possible lead time.

Judy. Wong

Purchasing Director

Chang

Q.C Manager

Jack. Zheng

Financial Officer

Gang. Wang

R&D Engineer

Janeford

Sales Manager

JD. Paul

Production Manager

Yong

Marketing Director

Teng

H.R

Request A Free Quote

Have any questions about laser parts?

Don’t hesitate to contact us. Lasersourcing’s product specialists are very happy to help you and provide a variety of flexible and reliable solutions to help you solve various problems.

Tel

+86-15370952128

lasersourcing@hotmail.com

15370952128

+86-15370952128