Laser Ceramic Ring Manufacturer & Wholesaler

- Fiber Laser & Co2 Laser

- Real Factory Beased In China,Factory direct sales

- Customized on request

- Full range of ceramic part

Why Choose Lasersourcing Ceramic Part ?

Boost Your Business With Our High Quality Nozzles

Full range of models

We offer the option of producing a wide range of laser cutting machine ceramic part to ensure you get the right solution for your product. Adaptable to most of the major laser machine brands on the market today, such as AMADA®, BYSTRONIC®, BODOR®, HAN'S LASER®, HANKWANG®, MAZAK®, MITSUBISHI®, NUKON®, PRECITEC®, PENTA®, PRIMA POWER®. RAYTOOLS®, TRUMPF®, etc. In order to make the production process as easy and efficient as possible, our staff will communicate with you fully. All you need to do is to inform us about the parameters of the nozzle or provide us with a complete sample.

High precision

Lasersourcing uses state-of-the-art, high-precision CNC machines with advanced technology and high machining precision to ensure that the ceramic part are manufactured to the highest level of performance.

Long life

Lasersourcing's ceramic part are made from high quality aluminum oxide for long life and are more durable than those commonly available on the market.And high-purity copper needles for more sensitive sensing.

Support customization

We not only offer the mainstream laser ceramic part currently on the market, but in addition, we are able to provide you with some special laser ceramic part for manufacturing, giving you more options.

Competitive price

We do not pursue cheap but poor quality products, nor do we pursue high quality but uncompetitive price products, we can pursue is to provide you with high quality products at a reasonable price. By selling our products for you to bring more customers and profits is our purpose.

How to make qualified laser Ceramic Part ?

Step 1: Feeding

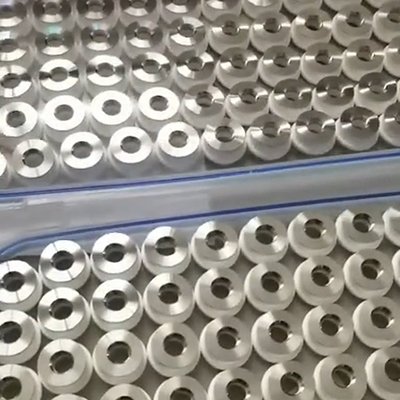

Selected alumina raw materials with purity up to 95%, with high strength, wear and corrosion resistance, can improve the service life of ceramic part; so that your customers can repeat purchase.

Step 3:Cleaning and Polishing

We clean and polish each ceramic body to remove edge burrs and aluminum oxide dust from the pressing process

Step 5:Chrome plating

Quality Inspection In this step, we will check the finished ceramic part, we will pick out all the products with defective quality, to ensure that each ceramic part is perfect to you.

Step 2:Processing

Adopt industrial ceramic dry press molding process. High processing efficiency for rapid production. High processing quality and high product stability.

Step 4:Welding

Each qualified ceramic part needs to be soldered. Our operators have rich experience in soldering and can precisely grasp each solder joint so that the ceramic part can achieve the best capacitance sensitivity.

Step 6:Packaging

We will package the products according to your requirements, we can customize the packaging, logo for you, so that you can spread your own brand more easily.

Commonly used Ceramic Part of various brands

| No. | Applicable brands | Product | Reference Code |

|---|---|---|---|

| 1 | ACCURL | KT B2 CON | P0571-1051-00001 / 6930281333 |

| ACCURL | KT B2 | P0571-260-00001 | |

| 2 | ADIRA | KT B2 CON | P0571-1051-00001 / 6930281333 |

| 3 | AMADA | INSULATION CERAMIC DISC | |

| AMADA | INSULATION DISC | 71341614A / 1669779 | |

| 4 | AMADA MITSUBISHI | P0594-860-00001 | |

| 5 | BALLIU | M1.5 DXN II | P0497-68871 / 29100388 / 29100106 |

| BALLIU | KT B2 CON | P0571-1051-00001 / 6930281333 | |

| 6 | BLM ADIGE | M12x1 | 6930003224 |

| BLM ADIGE | KT B2 CON | P0571-1051-00001 / 6930281333 | |

| BLM ADIGE | M1.5 KS | P0491-130-00001 | |

| BLM ADIGE | M1.5 KN | P0494-752-00001 / 0092405 / 6930300016 | |

| BLM ADIGE | NUT FOR CERAMIC KN | P0494-940-00001 | |

| BLM ADIGE | PRECITEC INSULATOR IT B2 Z | P0571-265-00001 | |

| BLM ADIGE | SEAL FOR M1.5 KN | P0494-758-00001 | |

| 7 | BODOR | M11 | A0-NOZ-D00051 |

| BODOR | 3D M8 | 31220000006 | |

| BODOR | M14 | 120274100B | |

| BODOR | KT B2 | P0571-260-00001 | |

| 8 | BYSTRONIC | BYSPEED 3015/4020 BYAUTONOM 4400 | 3-13113-1 |

| BYSTRONIC | BYSPEED 3015/4020 BYAUTONOM 4400 | 3-13422 | |

| BYSTRONIC | BYSPEED 3015/4020 BYAUTONOM 4400 | 10011659 | |

| BYSTRONIC | BYLAS BYJOB 3015/4020 BYSPRINT / BYSTAR / BYSTAR PROFESSIONAL | 4-01959 | |

| BYSTRONIC | BYLAS BYJOB 3015/4020 BYSPRINT / BYSTAR / BYSTAR PROFESSIONAL | 4-01642 | |

| BYSTRONIC | 3015/4020 BYSPRINT / BYSTAR / BYSTAR PROFESSIONAL | 4-09010 | |

| BYSTRONIC | {04} LASER FIBER CHANGE UG. MANUAL and AUTOMATIC | 10046025 | |

| BYSTRONIC | 3015/4020 BYSPRINT / BYSTAR / BYSTAR PROFESSIONAL | 10032838 | |

| 9 | CINCINNATI | INSULATOR RING | 923259 |

| 10 | CR ELECTRONIC | CR ELECTRONIC LASER FOCUS HEAD CR | |

| CR ELECTRONIC | KT B2 CON | P0571-1051-00001 / 6930281333 | |

| 11 | CUTLITE PENTA | M11 | 80800302 |

| CUTLITE PENTA | M12x1 | 6930003224 | |

| CUTLITE PENTA | KT B2 CON | P0571-1051-00001 / 6930281333 | |

| CUTLITE PENTA | M1.5 KN | P0494-752-00001 / 0092405/ 6930300016 | |

| 12 | DANOBAT | KT B2 CON | P0571-1051-00001 / 6930281333 |

| 13 | DURMA | M1.5 DXN II | P0497-68871 / 29100388 / 29100106 |

| DURMA | KT B2 CON | P0571-1051-00001 / 6930281333 | |

| 14 | ERMAKSAN | P0571-1051-00001 / 6930281333 | KT B2 CON |

| ERMAKSAN | P0595-92036 | KT X | |

| ERMAKSAN | P0595-94097 | KT XB | |

| 15 | ESAB | P0571-260-00001 | KT B2 |

| 16 | FINN-POWER | P0571-1051-00001 / 6930281333 | KT B2 CON |

| FINN-POWER | P0571-260-00001 | KT B2 | |

| 17 | GHT | P0571-1051-00001 / 6930281333 | KT B2 CON |

| 18 | HAN'S LASER | P0595-92036 | KT X |

| HAN'S LASER | P0595-94097 | KT XB | |

| 19 | HANKWANG | HCH-S01201 | |

| 20 | LVD | P0497-68871 / 29100388 / 29100106 | M1.5 DXN II |

| LVD | P0571-1051-00001 / 6930281333 | KT B2 CON | |

| 21 | MESSER | P0571-1051-00001 / 6930281333 | KT B2 CON |

| MESSER | P0571-265-00001 | PRECITEC INSULATOR IT B2 Z | |

| 22 | MICROSTEP | P0571-1051-00001 / 6930281333 | KT B2 CON |

| 23 | NUKON | P0571-1051-00001 / 6930281333 | KT B2 CON |

| NUKON | 3K1005 | INSULATING CERAMIC M11 | |

| 24 | PRECITEC | P0571-1051-00001 / 6930281333 | KT B2 CON |

| PRECITEC | P0595-92036 | KT X | |

| PRECITEC | P0595-94097 | KT XB | |

| PRECITEC | P0497-68871 | M1.5 DXN | |

| PRECITEC | P0494-752-00001 | M1.5 KN | |

| PRECITEC | P0491-130-00001 | M1.5 KS | |

| 25 | PRIMA POWER | P0571-1051-00001 / 6930281333 | KT B2 CON |

| PRIMA POWER | P0571-260-00001 | KT B2 | |

| 26 | PROMOTEC | P0571-1051-00001 / 6930281333 | KT B2 CON |

| 27 | SALVAGNINI | P0571-1051-00001 / 6930281333 | KT B2 CON |

| 28 | SHT | P0571-1051-00001 / 6930281333 | KT B2 CON |

| 29 | SOITAAB | 6930003224 | M12x1 |

| SOITAAB | P0571-1051-00001 / 6930281333 | KT B2 CON | |

| 30 | TANAKA | P0497-68871 / 29100388 / 29100106 | M1.5 DXN II |

| 31 | TECNIMETAL | P0571-1051-00001 / 6930281333 | KT B2 CON |

| 32 | TRUMPF | 260432 | FOR DIAS 3 |

| TRUMPF | 1755673 1349171 | M12 (also replaces 1349171) | |

| TRUMPF | P0494-752-00001 / 0092405 / 6930300016 | M1.5 KN | |

| TRUMPF | 1906032 | BRIGHTLINE/COOLLINE | |

| TRUMPF | 936678 - 913966 | COMPATIBLE | |

| TRUMPF | 258809 | COMPATIBLE | |

| TRUMPF | 258809 | ||

| 33 | WARCOM | P0497-68871 / 29100388 / 29100106 | M1.5 DXN |

| WARCOM | P0571-1051-00001 / 6930281333 | KT B2 CON | |

| WARCOM | P0595-92036 | KT X | |

| WARCOM | P0595-94097 | KT XB |

Still not finding what you're looking for? Contact our consultants for more available products.

Frequently Asked Questions

● General

For some products such as regular nozzles, protective lenses or ceramic parts if you don't need to print custom logo on the product or other special requirements, it will not charge any fee.

Just let us know your shipping collection account such as FedEx DHL TNT, if you don't have an account it will need to be charged appropriately for courier charges.

Stocked model 1pcs above

Customized size/design/shape, MOQ 100-1000pcs

● Product

No, it won't. Our materials are of high quality and each product is carefully checked by professionals before packaging.

● Customization

Yes, we welcome customer's design such as packaging, size, logo, pattern, etc.

We design and construct each project to the individual customer’s needs.

We can design and manufacture products according to the parameters you provide for nozzles, protective lenses, etc. We can also customize your product logo and product packaging. Even manufacturing processes such as coating, chrome plating, etc., we can provide.

● Service

Custom design - First make custom molds/logos/packages.

Sample-Produce sample for your inspection.

Confirm order-Sign sales contract after sample confirmation.

Deposit-Pay 40% deposit before mass production.

Arrange production- We will handle the production.

Remaining payment-After inspecting the goods, the remaining amount will be paid before shipment.

Shipping- We will ship the goods to the destination port.

Confirm loading list/commercial invoice/packing list/certificate of origin.

After-sales service.

a. For samples, 3-5 days working days for airfreight to the door.

b. For stock, 7 days for shipment to port of loading.

c. For mass production, 15-25 days production time is required. If a custom design is required, it will take another 7-10 days.

We are a professional supplier of parts for laser equipment. All of our products are available upon request. We will quote separately according to your actual needs. We do not have a price list.

We provide our customers one-stop station solutions in custom design, packing and other accessories.

● Payment

Payment less than 10000USD, 100% in advance. Payment more than 8000USD, 40% T/T in advance ,balance before shipment.

If you have another question, please feel free to contact us.

● Shipping

a. For small trial orders, by air or express: FEDEX, DHL, UPS, TNT, EMS, GATI, etc.

b. For large orders, we arrange sea or air freight according to your requirements.

Request A Free Quote

Have any questions about laser parts?

Don’t hesitate to contact us. Lasersourcing’s product specialists are very happy to help you and provide a variety of flexible and reliable solutions to help you solve various problems.

Tel

+86-15370952128

lasersourcing@hotmail.com

15370952128

+86-15370952128