Hypertherm Powermax 125: A Comprehensive Guide

I. Introduction

A. Definition of the Hypertherm Powermax 125

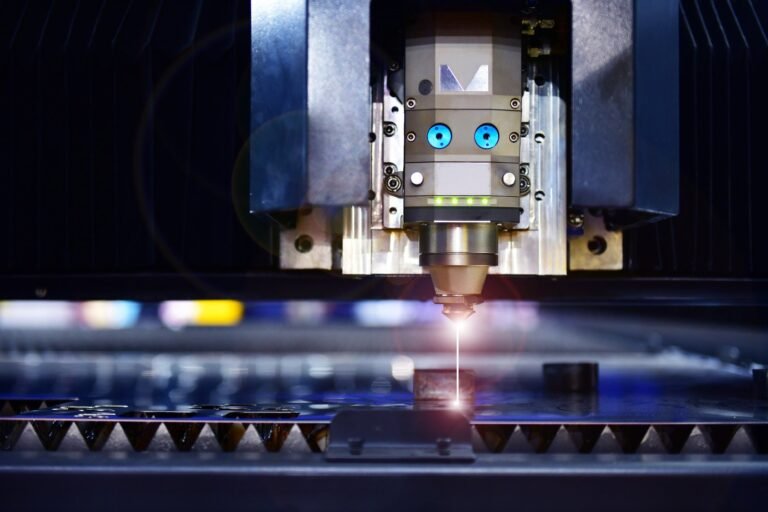

The Hypertherm Powermax 125 is a high-performing plasma cutter that is designed to handle heavy-duty cutting tasks with ease. It is one of the most popular plasma cutters in the market due to its excellent cutting capacity, user-friendly interface, and advanced features.

With its powerful 125-amp output, the Powermax 125 can cut through various types of metal, including steel, aluminum, and copper. It is also designed to deliver precise and clean cuts, making it an excellent choice for professional metalworkers, DIY enthusiasts, and hobbyists alike.

B. Brief overview of the article content

In this article, we will provide a comprehensive guide to the Hypertherm Powermax 125 plasma cutter. We will discuss its various features, cutting capacity, pierce capacity, price, and more. We will also cover the different consumables available for the system, as well as common fault codes and the user manual.

By the end of this article, you should have a thorough understanding of the Hypertherm Powermax 125 plasma cutter and be able to determine if it is the right choice for your cutting needs.

II. Features of the Hypertherm Powermax 125

A. Cutting capacity and pierce capacity

The Hypertherm Powermax 125 has an impressive cutting capacity of up to 1-1/4″ (32 mm) for mild steel, making it suitable for a wide range of metal cutting tasks.

The pierce capacity of the Powermax 125 is up to 5/8″ (16 mm), allowing you to create precise holes and intricate shapes in the metal.

B. Consumables compatibility

The Powermax 125 is compatible with a variety of consumables from different brands, giving you the flexibility to choose the right consumables for your specific cutting needs.

You can use consumables from Hypertherm, as well as other factory and brand products that are designed to work with the Powermax 125.

C. User-friendly interface

The Powermax 125 features a user-friendly interface that is easy to navigate, even for beginners.

The machine is equipped with a clear and intuitive LCD screen that displays all relevant information, such as the cutting mode, amperage, and consumables life.

D. Dual-angle design

The dual-angle design of the Powermax 125 torch allows you to easily switch between straight and 45-degree cutting, providing greater flexibility for different cutting applications.

This design also allows for better ergonomics and reduces operator fatigue during long cutting sessions.

E. Smart Sense technology

The Powermax 125 features Hypertherm’s patented Smart Sense technology, which automatically adjusts the gas pressure and consumables usage based on the thickness of the material being cut.

This technology ensures consistent cutting performance and maximizes consumables life, saving you time and money in the long run.

III. Hypertherm Powermax 125 Cutting Capacity

A. Thickness capacity

The Hypertherm Powermax 125 is a high-performance plasma cutter that is designed to handle a variety of metal cutting tasks with ease. One of its most notable features is its impressive thickness capacity, which allows it to cut through a wide range of metals, including steel, aluminum, and copper.

The Powermax 125 has a thickness capacity of up to 1-1/4″ (32 mm) for mild steel, 1″ (25 mm) for stainless steel, and 1″ (25 mm) for aluminum. This makes it suitable for a wide range of cutting applications, from light fabrication work to heavy-duty industrial cutting.

B. Cut chart overview

To make it easy for users to determine the appropriate settings for their cutting tasks, Hypertherm provides a cut chart for the Powermax 125 plasma cutter. The cut chart provides information on the recommended cutting speed, amperage, and air pressure settings for different types of metals and thicknesses.

The cut chart is available in the Powermax 125 manual and can also be accessed online. It is an essential tool for achieving precise and clean cuts with the Powermax 125 plasma cutter.

C. Pierce capacity

In addition to its impressive thickness capacity, the Powermax 125 also has an excellent pierce capacity. The pierce capacity refers to the maximum thickness of the metal that the cutter can pierce through to initiate a cut.

The Powermax 125 has a pierce capacity of up to 5/8″ (16 mm), making it suitable for creating precise holes and intricate shapes in the metal. This feature allows for greater versatility in cutting tasks and makes the Powermax 125 an excellent choice for a wide range of applications.

IV. Hypertherm Powermax 125 Price and Manual

A. Cost overview

The Hypertherm Powermax 125 is a high-performance plasma cutter that comes with a relatively high price tag. The cost of the Powermax 125 varies depending on the vendor and the package you purchase, but generally ranges between $3,000 and $4,000.

While the cost may seem high compared to other plasma cutters in the market, the Powermax 125’s advanced features, cutting capacity, and durability make it a worthwhile investment for those who need a high-performing plasma cutter for their cutting tasks.

B. Powermax 125 manual PDF availability

Hypertherm provides a comprehensive user manual for the Powermax 125 plasma cutter, which includes information on how to set up and use the machine, as well as troubleshooting tips and maintenance guidelines.

The manual is available in both hard copy and PDF format, with the latter being readily available for download on the Hypertherm website or other online sources. The PDF manual is convenient for those who prefer digital copies and can be easily accessed on a computer or mobile device.

C. Comparison to other plasma cutters in the market

When considering the cost of the Powermax 125, it is important to compare it to other plasma cutters in the market to determine its value. While the Powermax 125 is relatively expensive, it is worth noting that it is a top-of-the-line plasma cutter with advanced features and exceptional cutting performance.

Compared to other plasma cutters in its class, the Powermax 125 is highly competitive in terms of cutting capacity, durability, and user-friendliness. It is also compatible with a wide range of consumables, making it a versatile cutting tool for various applications.

V. Hypertherm Powermax 125 Consumables

A. Overview of consumables

Consumables are an essential component of any plasma cutter, including the Hypertherm Powermax 125. They refer to the parts that wear out over time and need to be replaced periodically to maintain the cutter’s performance.

The Powermax 125 uses a range of consumables, including nozzles, electrodes, swirl rings, and shields, to provide optimal cutting performance. The consumables are designed to be durable and long-lasting, but they will eventually need to be replaced after extended use.

B. Compatible brands and factory products

The Powermax 125 is compatible with a variety of consumables from different brands and factory products. This gives users greater flexibility in choosing the consumables that best suit their cutting needs and budget.

Hypertherm provides its own consumables for the Powermax 125, which are known for their high quality and durability. Other brands and factory products that are compatible with the Powermax 125 include Thermal Dynamics, SÜA, and more.

C. Common replacement parts and maintenance

Some of the most common replacement parts for the Powermax 125 include nozzles, electrodes, and swirl rings. These parts wear out over time and need to be replaced periodically to ensure optimal cutting performance.

To maintain the performance and longevity of the Powermax 125, regular maintenance is also necessary. This includes cleaning the torch regularly, checking the consumables for wear and tear, and replacing them as needed. It is also important to follow the manufacturer’s guidelines for maintenance and replacement schedules to ensure the cutter’s optimal performance.

D. Common replacement parts list

220971 Electrode 35A – 125A

220997 Swirl Ring 35A – 125A

420158 Nozzle 45A

420169 Nozzle 65A

220975 Nozzle 105A-125A

220977/65 Retaining Cap 35A – 65A

220977/125 Retaining Cap 105-125A

420156/65 Retaining Cap OHMIC 35 – 65A

420156/125 Retaining Cap OHMIC 105 – 125A

420172 Manual Shield 35-65A

420000 Manual Shield 105-125A

220976 Gouging Shield Cap

420168 Machine Shield Cap 35-65A

220976 Machine Shield Cap 105A – 125A

420159 Precision Cut Swirl Ring (manual cutting)

420151 Nozzle 30-45A Precision Cut

420152 Deflector

VI. Hypertherm Powermax 125 Fault Codes

A. Explanation of fault codes

Fault codes are error messages that the Powermax 125 displays on its LCD screen when it encounters a problem or issue with its operation. These fault codes are essential for troubleshooting and diagnosing issues with the cutter.

The Powermax 125 comes with a range of fault codes that indicate various issues with the machine, such as overheating, low air pressure, and consumables issues. Each fault code corresponds to a specific issue, which is explained in the Powermax 125 manual.

B. Troubleshooting guide

When a fault code appears on the Powermax 125, it is essential to refer to the troubleshooting guide in the manual to determine the issue and how to resolve it. The manual provides step-by-step instructions on how to troubleshoot various issues, from simple fixes like replacing a consumable to more complex issues like adjusting the gas pressure.

It is important to follow the manufacturer’s guidelines for troubleshooting and resolving issues to avoid further damage to the cutter. If the issue cannot be resolved through troubleshooting, it may be necessary to contact the manufacturer or a qualified technician for assistance.

C. Fault code example

Code 0-21-0

Excessive arc voltage. The DSP monitors the nozzle to electrode voltage and if it detects a rapid change in voltage, the inverter shuts down. The suggested solution is to check consumables and gas flow.

Code 0-30

This is the most common fault code seen on the Powermax65, Powermax85, Powermax105, and Powermax1252.

Code 0-12

This code indicates that the gas pressure isn’t between 85 and 135 psi when flowing

If you need more fault codes and their solutions, you can contact us for the full manual.

VII. Conclusion

A. Summary of the Hypertherm Powermax 125 plasma cutter

The Hypertherm Powermax 125 is a high-performance plasma cutter that is designed to handle a wide range of metal cutting tasks with ease. Its advanced features, including an impressive cutting capacity, pierce capacity, consumables compatibility, user-friendly interface, dual-angle design, and Smart Sense technology, make it a top choice for professionals and DIY enthusiasts alike.

The Powermax 125’s compatibility with a range of consumables and availability of a comprehensive manual make it a valuable addition to any metalworking toolkit. While it has a relatively high price tag compared to other plasma cutters in the market, its exceptional cutting performance, durability, and ease of use make it a worthwhile investment for those who require a high-performing plasma cutter for their cutting tasks.

B. Final thoughts and recommendations

Overall, the Hypertherm Powermax 125 plasma cutter is a powerful and versatile cutting tool that provides exceptional cutting performance and ease of use. Its impressive features and durability make it a worthwhile investment for professionals and DIY enthusiasts alike.

To get the most out of the Powermax 125, it is important to follow the manufacturer’s guidelines for maintenance, consumables replacement, and troubleshooting. This will ensure optimal cutting performance and longevity of the cutter.

If you are in the market for a high-performing plasma cutter that can handle a wide range of metal cutting tasks, the Hypertherm Powermax 125 is an excellent choice. Its advanced features, exceptional cutting capacity, and compatibility with various consumables make it a valuable addition to any metalworking toolkit.