Hypertherm MAXPRO200: A Comprehensive Guide

Hypertherm MAXPRO200 is an advanced plasma cutting system that offers high-quality cuts, precision, and speed. The system uses plasma technology to cut through different materials such as steel, aluminum, and copper. In this article, we will discuss everything you need to know about the Hypertherm MAXPRO200 system, including its features, benefits, and applications.

1. What is Hypertherm MAXPRO200?

Hypertherm MAXPRO200 is a plasma cutting system designed for industrial use. The system is capable of cutting through a variety of materials, including mild steel, stainless steel, and aluminum. It is equipped with advanced plasma technology that enables it to produce clean, precise, and high-quality cuts. The system is used in various industries such as metal fabrication, automotive, and shipbuilding.

2. How Does Hypertherm MAXPRO200 Work?

The Hypertherm MAXPRO200 system works by using plasma technology to cut through different materials. The system generates an electric arc that passes through a gas, usually compressed air, creating plasma. The plasma then melts the material being cut, and the compressed air blows away the molten metal. The process produces precise cuts, clean edges, and minimal dross.

3. Features of Hypertherm MAXPRO200

Versatile Cutting Capabilities

The Hypertherm MAXPRO200 system is capable of cutting a wide range of materials, including mild steel, stainless steel, and aluminum. It can also cut through non-ferrous metals, such as copper and brass, as well as other conductive materials.

Fast and Precise Cutting

The system offers fast cutting speeds, reducing production time and increasing efficiency. It is also capable of producing precise cuts with clean edges, reducing the need for secondary operations such as grinding or finishing.

Durability and Longevity

The Hypertherm MAXPRO200 system is built to last, with a durable design and high-quality components. The system is also designed to withstand harsh industrial environments, ensuring longevity and reliability.

Easy to Use

The system is designed to be user-friendly, with an intuitive interface and simple controls. It also comes with a range of helpful features such as automatic gas control and easy-to-change consumables, making it easy to maintain and operate.

4. Benefits of Hypertherm MAXPRO200

Increased Efficiency

The fast cutting speed of the Hypertherm MAXPRO200 system reduces production time, increasing efficiency and productivity. The system also produces minimal dross, reducing the need for secondary operations, further improving efficiency.

Enhanced Productivity

The system’s precise cutting capabilities and user-friendly design enable operators to produce high-quality cuts quickly and easily. This enhances overall productivity, reducing production costs and increasing profitability.

Reduced Operating Costs

The system’s durable design and high-quality components reduce the need for maintenance and repairs, minimizing operating costs. The system’s efficient use

of consumables also reduces costs, as the system uses them efficiently and effectively, maximizing their lifespan.

High-Quality Cuts

The Hypertherm MAXPRO200 system produces high-quality cuts with clean edges and minimal dross. This ensures that the finished product meets the required specifications, improving the overall quality and value of the product.

5. Applications of Hypertherm MAXPRO200

The Hypertherm MAXPRO200 system is used in various industries and applications, including:

Metal Fabrication

The system is used for cutting and shaping metal parts for various applications, including machinery, equipment, and structures.

Automotive Industry

The Hypertherm MAXPRO200 system is used for cutting and shaping metal parts for cars, trucks, and other vehicles.

HVAC and Ductwork

The system is used for cutting and shaping metal parts for HVAC systems and ductwork.

Shipbuilding and Marine Industry

The system is used for cutting and shaping metal parts for ships, boats, and other marine applications.

6. Maintenance and Care of Hypertherm MAXPRO200

To ensure the longevity and optimal performance of the Hypertherm MAXPRO200 system, regular maintenance and care are essential. This includes:

- Regular cleaning and inspection of the system

- Replacement of consumables as needed

- Lubrication of moving parts

- Calibration and adjustment of the system as needed

By following these maintenance and care guidelines, the Hypertherm MAXPRO200 system can provide reliable and high-quality cutting for years to come.

7. Frequently Asked Questions (FAQs)

- What materials can the Hypertherm MAXPRO200 system cut? The system is capable of cutting a wide range of materials, including mild steel, stainless steel, aluminum, copper, and other conductive materials.

- How fast is the cutting speed of the Hypertherm MAXPRO200 system? The cutting speed of the system can reach up to 500 inches per minute, depending on the material being cut and the thickness of the material.

- What is the lifespan of the consumables used in the Hypertherm MAXPRO200 system? The lifespan of the consumables varies depending on the material being cut and the cutting conditions. However, with proper use and maintenance, the consumables can last for a significant period.

- Is the Hypertherm MAXPRO200 system user-friendly? Yes, the system is designed to be user-friendly, with an intuitive interface and simple controls. It also comes with a range of helpful features to make operation and maintenance easy.

- What industries use the Hypertherm MAXPRO200 system? The system is used in various industries such as metal fabrication, automotive, HVAC, and shipbuilding, where high-quality cuts and precision are essential.

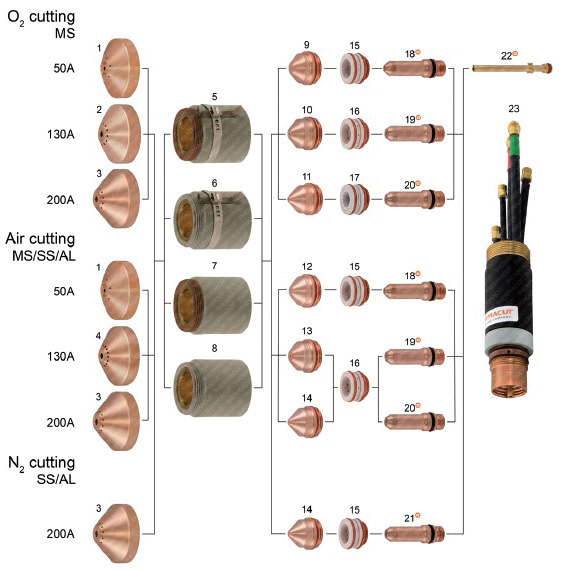

8. Common accessories for MaxPro200

Shields:

220532 Shield 45-50A

220491 Shield 130A O2

220832 Shield 200A O2

220536 Shield 130A – Air

Retaining Caps:

220936 Retaining cap OHMIC

220936-UR Retaining Cap 50-200A, O2/Air (200A, N2)

220935 Retaining cap

220935-UR Retaining Cap 50-200A, O2/Air (200A, N2) w/o IHS

Deflector Supports:

220490

220578

Nozzles:

220891-UR Nozzle 50A, O2

220893-UR Nozzle 130A, O2

220831-UR Nozzle 200A, O2

220890 Nozzle 50A O2

220892 Nozzle 130A Air

420044-UR Nozzle 200A, O2/Air/N2

Diffusers:

220529 Diffuser 45A air, 50A O²

Swirl Rings:

220488 Swirl ring 130A

220834 Swirl Ring 200A O2 Max Life

Electrodes:

220528 Electrode 50A Air/O2

220487 Electrode 130A Air/O2

220937-UR Electrode 200A, O2/Air

020415-UR Electrode 100-200A

Plunge Tube:

220521-UR Plunge Tube

Conclusion

The Hypertherm MAXPRO200 is a high-quality plasma cutting system that offers fast and precise cutting for a variety of materials. Its user-friendly design, durability, and longevity make it an ideal choice for various industrial applications. By understanding its features, benefits, and applications, you can make an informed decision about whether the Hypertherm MAXPRO200 system is right for your needs.