How To Cut Metal With Laser

I. Introduction

Definition of Laser Cutting

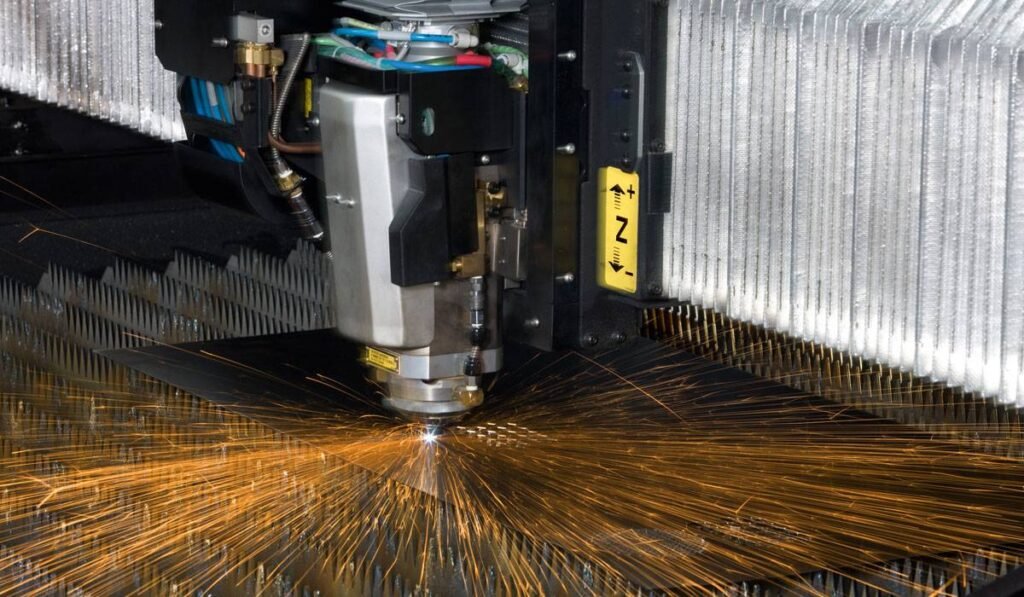

Laser cutting is a process that uses a focused beam of light to cut through various materials, including metals, plastics, and wood. The laser beam melts, vaporizes, or burns the material, creating a precise and clean cut.

Importance of Laser Cutting in the Metalworking Industry

Laser cutting has become a crucial process in the metalworking industry, as it offers high precision, speed, and accuracy compared to traditional cutting methods. It also allows for intricate and complex designs to be created with ease, making it a popular choice for many industries.

Overview of the Article

This article will cover various aspects of laser cutting, including the types of lasers used to cut metal, the thickness of metal that can be cut, the cost of laser cutting machines, and more. We will also explore popular brands in the industry, such as Bodor Laser and Glowforge, and provide information on the best laser engravers for metal.

II. How Laser Cutting Works

Laser cutting is a technology that uses a high-powered laser beam to cut materials, including metal. Here are some basic principles of how laser cutting works, the types of lasers used in metal cutting, and the advantages of laser cutting:

Basic Principles of Laser Cutting

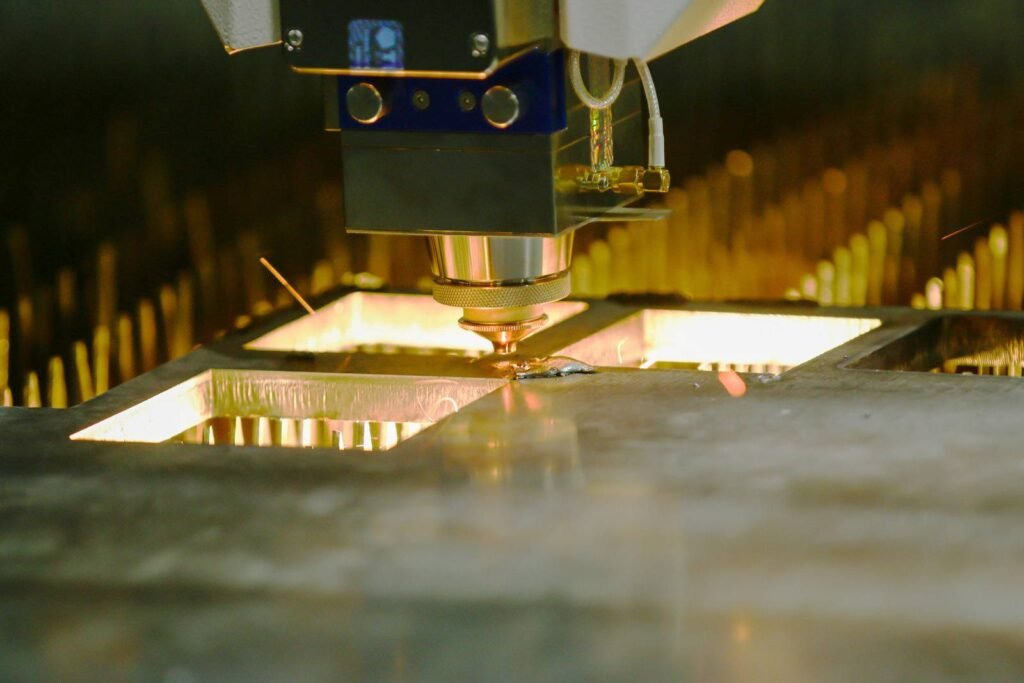

A laser beam is focused onto a material to be cut, melting, burning, or vaporizing it along the cutting line.

The laser beam is guided by a computer-controlled system to create the desired shape or pattern.

A gas, such as nitrogen or oxygen, is used to blow away the melted or vaporized material, leaving a clean edge.

Types of Lasers Used in Metal Cutting

CO2 lasers: This type of laser uses a mixture of carbon dioxide, helium, and nitrogen to produce a high-powered laser beam that can cut through thick metal materials.

Fiber lasers: This type of laser uses optical fibers to amplify the laser beam, producing a more efficient cutting process than CO2 lasers.

Nd:YAG lasers: This type of laser is typically used for precision cutting of thin metals and other materials.

Advantages of Laser Cutting

Precision and accuracy: Laser cutting provides precise cuts with high accuracy, allowing for intricate designs and shapes.

Speed: Laser cutting can be a fast process, particularly with fiber lasers, reducing production time.

Versatility: Laser cutting can be used on a wide range of materials, including metals, plastics, and wood.

Less material waste: Laser cutting produces minimal waste compared to traditional cutting methods, reducing material costs.

III. Commonly Cut Metals with Laser Cutting

Laser cutting is a popular metal cutting method that can be used on various types of metals. Here are some of the most commonly cut metals with laser cutting:

Stainless Steel

Stainless steel is a popular metal for laser cutting due to its high resistance to corrosion and durability.

Laser cutting is used in various industries for cutting stainless steel, including the aerospace and automotive industries.

Aluminum

Aluminum is a light-weight metal that can be easily cut with laser cutting.

Laser cutting is commonly used in the fabrication of aluminum parts in industries such as aerospace and automotive.

Copper

Copper is a soft metal that can be challenging to cut with traditional methods, but it is easily cut with laser cutting.

Laser cutting is used in the manufacturing of copper parts in various industries such as electronics and plumbing.

Brass

Brass is an alloy made of copper and zinc and is a popular material for decorative and architectural purposes.

Laser cutting is commonly used for cutting brass in the production of various decorative items such as ornaments and sculptures.

Iron

Iron is a strong and durable metal commonly used in the construction and automotive industries.

Laser cutting is a popular method for cutting iron due to its precision and speed.

IV. Laser Cutting Machines and Equipment

Laser cutting machines are essential tools in the metalworking industry. They come in different types and brands, and their prices are influenced by various factors. Here are some key points to consider:

Types of Laser Cutting Machines

CO2 Laser Cutting Machines:

Use a gas mixture to generate the laser beam

Can cut non-metal materials such as plastics, wood, and fabric in addition to metals

Lower cost compared to fiber laser cutting machines

Suitable for cutting thinner metals and materials

Fiber Laser Cutting Machines:

Utilize fiber optic cables to generate the laser beam

Offer high cutting speeds and precision for metal cutting

Can cut thicker metals than CO2 laser cutting machines

Higher cost compared to CO2 laser cutting machines

Crystal Laser Cutting Machines:

Use a crystal as the laser source

Offer high cutting precision and speed

Typically used for cutting non-metal materials such as ceramics and glass

Less common in the metalworking industry compared to CO2 and fiber laser cutting machines

Laser Cutting Machine Brands

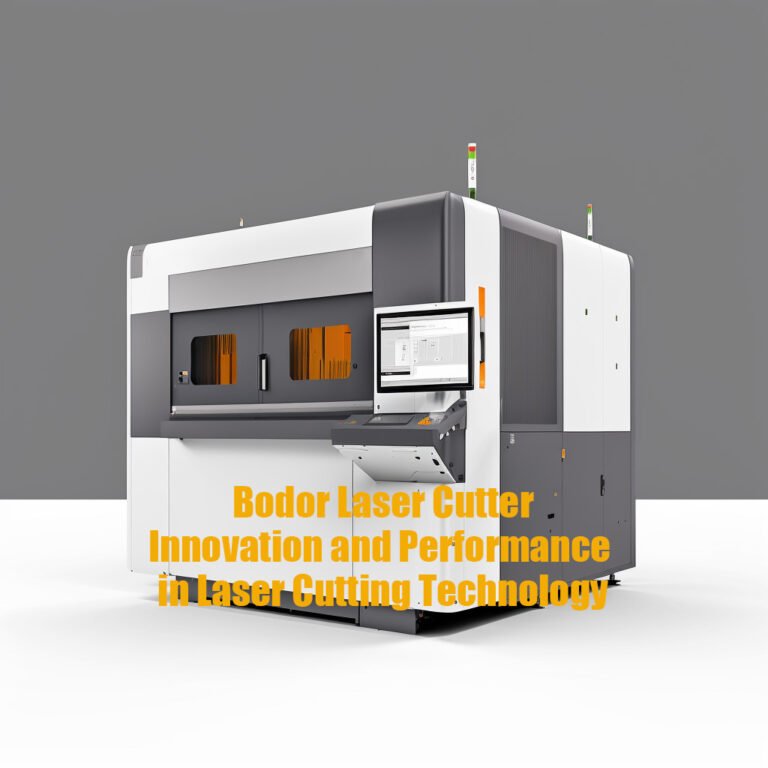

Bodor Laser

PT High Power Laser Sheet Metal

OSH Cut Laser

Glowforge

Boss Laser

Universal Laser Systems

Amada

Mazak

TRUMPF

Bystronic

Laser cutting machine brands are numerous and varied, each with their own strengths and weaknesses. Some popular brands include Bodor Laser, which offers a range of laser cutting machines for both metal and non-metal materials. PT High Power Laser Sheet Metal is another brand that specializes in high-power laser cutting machines for sheet metal applications. OSH Cut Laser and Glowforge are popular options for small-scale laser cutting and engraving. Boss Laser and Universal Laser Systems offer a wide range of laser cutting and engraving machines for various industries. Amada, Mazak, TRUMPF, and Bystronic are well-known brands in the industrial laser cutting market, offering high-end, high-precision machines for large-scale metal cutting operations.

Factors Affecting Laser Cutting Machine Prices

Laser Power

The higher the laser power, the higher the cost of the machine.

Bed Size

Larger bed sizes will cost more than smaller ones.

Machine Type

Different types of laser cutting machines have varying costs.

Brand

The brand of the machine can affect its cost.

Additional Features

Additional features such as automatic loading and unloading systems or integrated CAD/CAM software will add to the cost of the machine.

Warranty

Longer or more comprehensive warranties can increase the cost of the machine.

Maintenance and Support

The cost of maintenance and support services should also be factored in when considering the overall cost of the machine.

V. Laser Cutting vs. Traditional Metal Cutting Methods

Laser cutting is a popular method for cutting metals, but how does it compare to traditional metal cutting methods? Let’s take a look at some of the key differences.

Comparison of Laser Cutting and Plasma Cutting

Plasma cutting is a method of cutting metals using a plasma torch. Plasma cutting is typically faster and more efficient than laser cutting for thicker materials. However, laser cutting produces a cleaner cut and can be more precise than plasma cutting.

Comparison of Laser Cutting and Waterjet Cutting

Waterjet cutting uses a high-pressure jet of water to cut materials. While waterjet cutting can cut a wide range of materials, including metals, it is typically slower than laser cutting. Laser cutting also produces less waste material and can be more precise than waterjet cutting.

Comparison of Laser Cutting and Flame Cutting

Flame cutting, also known as oxy-fuel cutting, uses a flame to heat and melt metal, which is then cut with a jet of oxygen. Flame cutting is typically used for thicker materials and is often more cost-effective than laser cutting. However, laser cutting produces a cleaner cut and can be more precise than flame cutting.

Overall, laser cutting is a highly precise and efficient method of cutting metals. While traditional metal cutting methods may be more cost-effective for certain applications, laser cutting offers unparalleled precision and speed for many metalworking needs.

VI. Frequently Asked Questions About Laser Cutting Metal section:

What thickness of metal can a laser cut?

Laser cutting machines can typically cut through metals up to 25mm thick, depending on the power of the laser used and the type of metal being cut.

How strong of a laser is needed to cut metal?

The strength of the laser needed to cut metal depends on the type and thickness of the metal. Generally, a laser with a power output of 500W or more is needed for cutting metals up to 12mm thick.

Can a 100W CO2 laser cut metal?

A 100W CO2 laser can cut through thin sheets of metal, but it is not recommended for cutting thick metal due to the limited power output.

Can a 150W laser cut metal?

A 150W laser is capable of cutting through thicker metal than a 100W CO2 laser, but it is still not recommended for cutting metals over a certain thickness.

What material cannot be cut by laser?

Materials that cannot be cut by laser include reflective materials such as copper and brass, as well as some plastics that release toxic gases when cut.

How thin can a laser cut metal?

Laser cutting machines are capable of cutting metals as thin as a few microns.

Can you laser engrave metal?

Yes, laser engraving is a popular application of laser cutting technology for metals. The laser beam can be used to etch designs, text, or images onto metal surfaces.

Can you laser cut titanium?

Yes, titanium can be cut with a laser cutting machine, but it requires a high-power laser due to its strength and density.

Does laser cutting warp metal?

Laser cutting can cause some warping of metal due to the heat generated by the laser beam. However, this can be minimized by using appropriate cutting parameters and supporting the metal during the cutting process.

VII. Laser Cutting Services

Metal Laser Cutting Near Me

When looking for metal laser cutting services near you, it’s important to find a reputable and experienced company that can handle your specific project needs. Many metal fabrication and machining companies offer laser cutting services as part of their capabilities, and it’s important to consider factors such as their equipment, materials, turnaround times, and pricing when choosing a provider.

Custom Laser Cut Metal

Custom laser cut metal allows for precise and intricate designs to be created in a variety of metals such as stainless steel, aluminum, and brass. Many laser cutting companies offer custom metal cutting services, allowing for unique and personalized projects to be completed. When choosing a provider for custom laser cut metal, it’s important to consider their equipment capabilities, design expertise, and pricing.

Small Fiber Laser Cutting Machine

Small fiber laser cutting machines are becoming more widely available, offering a cost-effective solution for small-scale metal cutting projects. These machines typically have lower power output but can still provide high accuracy and efficiency for cutting thin materials. When considering a small fiber laser cutting machine, it’s important to evaluate the machine’s power output, size, and cost.

Stainless Steel Laser Cutting Near Me

Stainless steel laser cutting services are commonly used in industries such as aerospace, automotive, and medical due to the material’s strength, corrosion resistance, and aesthetic appeal. When searching for stainless steel laser cutting services near you, it’s important to find a company with the necessary equipment and experience to handle stainless steel, as it can be more difficult to cut than other metals.

In summary, laser cutting services offer a variety of options for metal cutting projects, from custom designs to small-scale cutting machines. When searching for a provider, it’s important to consider factors such as their equipment capabilities, expertise, and pricing to ensure your project is completed with precision and efficiency.

VIII. Conclusion

Summary of Key Points

In summary, laser cutting is an important process in the metalworking industry that offers many advantages over traditional cutting methods. It provides high accuracy, efficiency, and flexibility for a wide range of metals.

When looking for laser cutting services, it’s important to consider factors such as location, equipment, and experience. Many companies offer custom laser cutting services for unique and complex projects, and there are various types of laser cutting machines available on the market from top brands such as Bodor, Glowforge, and PT High Power Laser Sheet Metal.

Final Thoughts and Recommendations.

In conclusion, laser cutting is a versatile and efficient metal cutting method that offers many benefits. When choosing a laser cutting service, it’s essential to research and consider various factors to ensure the best results for your project.

一条评论