How Does a Laser Rust Removal Machine Work? Exploring the Technology and Advantages

Rust is a common problem that affects metals, such as iron and steel, when they are exposed to moisture and oxygen. Rust not only affects the appearance of the metal but also weakens its structure, leading to potential safety hazards and costly repairs. Traditional rust removal methods, such as sandblasting and chemical cleaning, can be time-consuming, labor-intensive, and environmentally harmful. To address these challenges, laser technology has emerged as an efficient, precise, and eco-friendly solution for rust removal. In this article, we will explore the technology and advantages of laser rust removal machines.

How Does Laser Rust Removal Work?

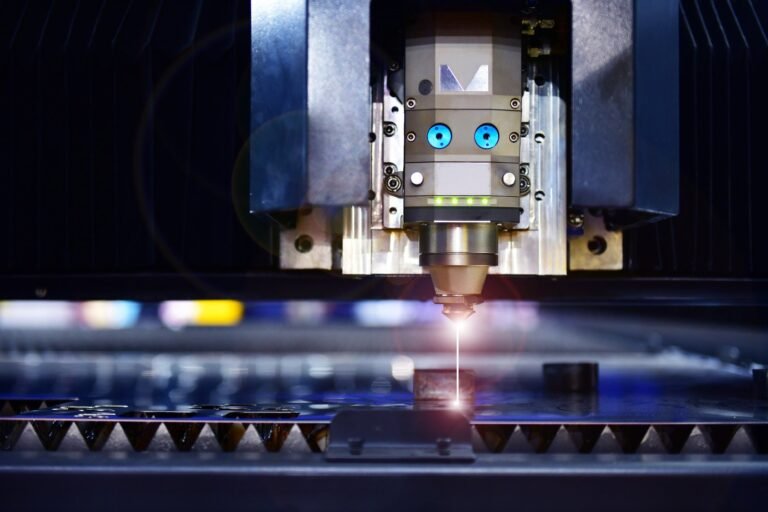

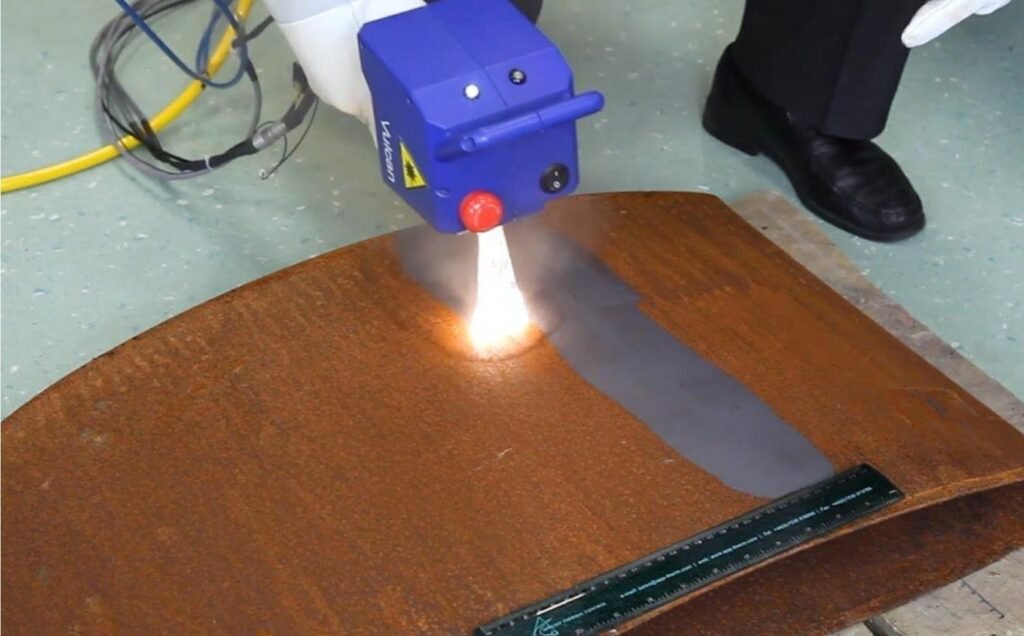

Laser rust removal works by using a high-intensity laser beam to remove rust from the surface of the metal. The laser beam is directed towards the rusted area using a scanner or a robotic arm. The laser beam interacts with the rust, creating plasma and generating shockwaves that remove the rust.

The laser beam can be adjusted to meet the requirements of the rust removal process, including the intensity, the pulse duration, and the spot size. The laser rust removal process is non-contact, meaning that the laser beam does not touch the surface of the metal, reducing the risk of damage and contamination. The laser rust removal machine can be operated manually or automated, depending on the application.

Benefits of Laser Rust Removal

Laser rust removal has several advantages over traditional rust removal methods, including:

Efficiency: Laser rust removal can remove rust from the surface of the metal quickly and efficiently, reducing the cleaning time and increasing productivity.

Precision: Laser rust removal can be adjusted to target specific areas of the metal, providing precise cleaning and ensuring that only the rust is removed.

Environmental Friendliness: Laser rust removal does not use chemicals or abrasive materials, making it an eco-friendly alternative to traditional rust removal methods. It also produces minimal waste, reducing the environmental impact.

Safety: Laser rust removal is a safe cleaning method, as it does not produce dust, fumes, or other hazardous materials. It also reduces the risk of accidents and injuries associated with traditional cleaning methods, such as chemical exposure and physical strain.

Cost-effectiveness: Although the initial investment for a laser rust removal machine may be higher than traditional cleaning equipment, it can provide long-term cost savings due to its efficiency, precision, and minimal maintenance requirements.

Limitations of Laser Rust Removal

Despite its many benefits, laser rust removal has some limitations that need to be considered:

Surface Preparation: Laser rust removal may not be effective if the surface is not properly prepared, as the laser beam can bounce off or penetrate the metal, causing damage.

Highly Reflective Surfaces: Laser rust removal may not be effective on highly reflective surfaces, such as chrome or polished metal, as the laser beam can bounce back and cause damage.

Limited Availability: Laser rust removal technology is still relatively new, and not all rust removal services offer it as an option.

Applications of Laser Rust Removal

Laser rust removal has a wide range of applications in various industries, including:

Automotive Industry: Laser rust removal can be used to remove rust from automotive parts, such as engine components, brake systems, and exhaust pipes.

Aerospace Industry: Laser rust removal can be used to remove rust from aerospace components, such as turbine blades, jet engines, and landing gear.

Marine Industry: Laser rust removal can be used to remove rust from ships, boats, and other marine vessels, reducing maintenance costs and improving safety.

Conclusion

Laser rust removal is an efficient, precise, and eco-friendly solution for rust removal. It offers numerous benefits over traditional rust removal methods, including efficiency, precision, environmental friendliness, safety, and cost-effectiveness. Its applications span various industries, including the automotive, aerospace, and marine industries.

Although laser rust removal has some limitations, such as the requirement for surface preparation and the limited availability of the technology, it has a promising future in the rust removal industry. As technology continues to evolve, laser rust removal machines are becoming more affordable and accessible to small businesses and individuals. Moreover, the technology is expected to improve, and its applications are likely to expand to cover more surfaces and materials.

If you are considering using laser rust removal for your rust removal needs, it is essential to research the available services and choose a reputable and experienced service provider. Laser rust removal requires specialized knowledge and expertise to operate safely and effectively, and working with a professional can ensure that your metal is cleaned thoroughly and safely.

In conclusion, laser rust removal is an efficient, precise, and eco-friendly solution for rust removal. It offers numerous benefits over traditional rust removal methods, including efficiency, precision, environmental friendliness, safety, and cost-effectiveness. Its applications span various industries, and it has a promising future in the rust removal industry. Although it has some limitations, it is worth considering for your rust removal needs.

Request A Free Quote

Have any questions about laser Cleaner?

Don’t hesitate to contact us. Lasersourcing’s product specialists are very happy to help you and provide a variety of flexible and reliable solutions to help you solve various problems.

Tel

+86-15370952128

lasersourcing@hotmail.com

15370952128

+86-15370952128