ESAB VS Hypertherm: How To Choose The Right Plasma Cutter

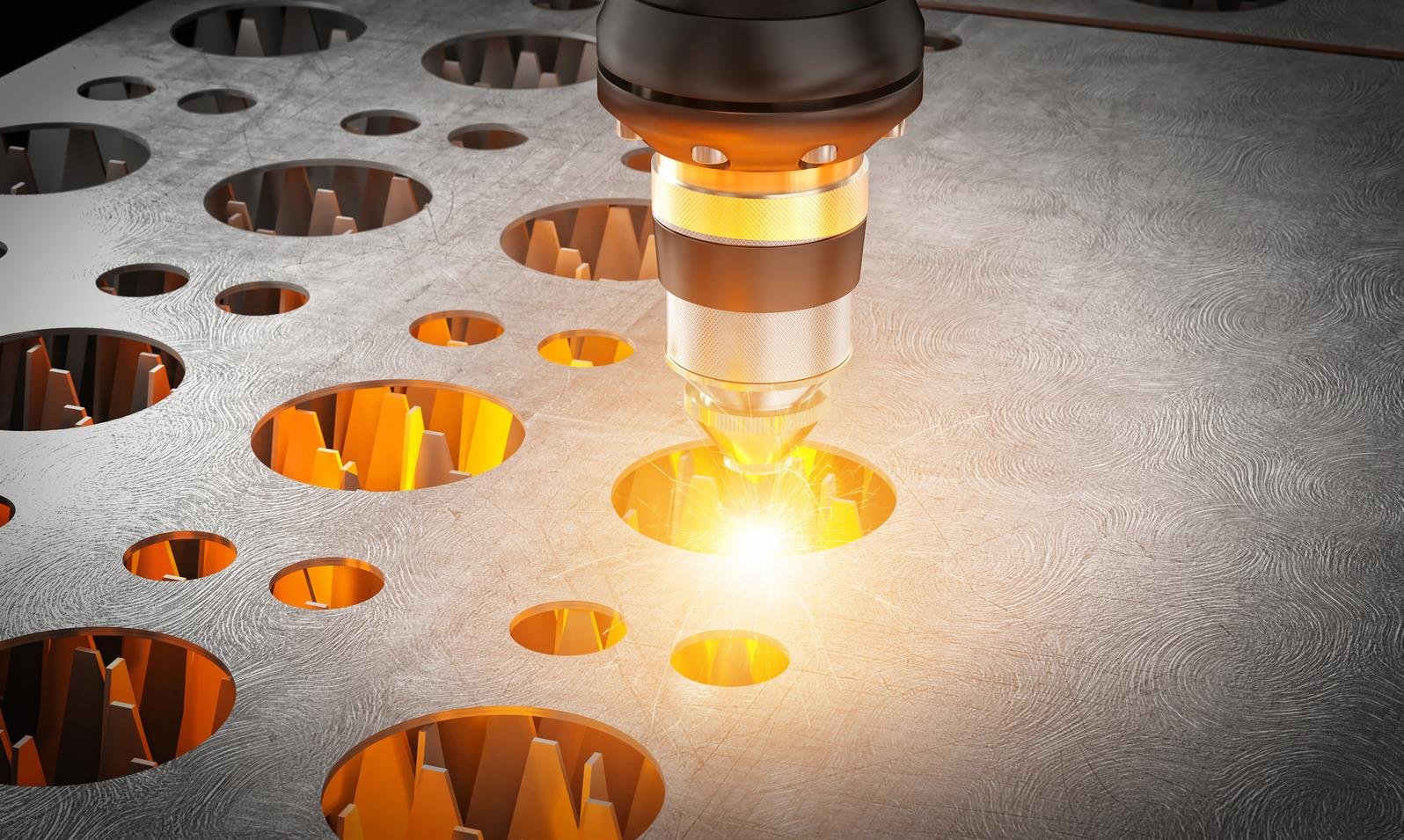

Plasma cutting technology has become an indispensable part of modern manufacturing, thanks to its high efficiency, accuracy, and versatility across various industries. However, choosing a plasma cutting machine that suits your needs can be challenging. In this article, we will compare the product features of two well-known plasma cutting equipment manufacturers, ESAB and Hypertherm, to help you make a more informed decision when choosing a plasma cutting machine.

ESAB Plasma Cutting Machines Overview

Company Background and Development

Founded in 1904 by Swedish inventor Oscar Kjellberg, ESAB (Electric Welding Limited) is a global leader in the field of cutting and welding equipment manufacturing. The company has a long history of innovation and has continuously expanded its product portfolio to meet the evolving needs of various industries. From its humble beginnings in Sweden, ESAB has grown into a multinational corporation with a presence in over 80 countries worldwide, offering a comprehensive range of welding consumables, equipment, and accessories.

Main Product Series and Features of ESAB Plasma Cutting Machines

ESAB offers a variety of plasma cutting machines that cater to the diverse needs of customers. Some of the main product series and their features include:

1. ESAB Cutmaster Series: The Cutmaster series of plasma cutting machines are designed for handheld applications and are known for their compact size, portability, and ease of use. These machines are ideal for small to medium-sized fabrication shops, maintenance and repair services, and on-site applications. The Cutmaster series features the TrueCut technology, ensuring high-quality cuts and superior performance.

2. ESAB Sabre Series: The Sabre series is designed for mechanized plasma cutting applications and is suitable for a wide range of industries, including shipbuilding, heavy fabrication, and construction. These machines are equipped with advanced features such as automatic gas control, precision arc voltage height control, and optional bevel cutting capabilities. The Sabre series is known for its high cutting speed, accuracy, and productivity.

3. ESAB Suprarex Series: The Suprarex series is a heavy-duty, gantry-style plasma cutting machine designed for large-scale industrial applications. These machines are built to handle thick materials and can be equipped with multiple cutting heads for increased productivity. The Suprarex series features advanced control systems, ensuring precise positioning and high-quality cuts. In addition, these machines can be easily integrated with other ESAB automation solutions, such as robotic welding systems.

Some key features of ESAB plasma cutting machines include:

1. High performance: ESAB equipment is known for its excellent cutting speed and precision, enabling the completion of a large number of jobs in a short time.

2. Easy to operate: ESAB equipment has an intuitive user interface, making it easy for users to get started quickly.

3. Durability: ESAB equipment is made from high-quality materials, offering a longer service life and lower maintenance costs.

Hypertherm Plasma Cutting Machines Overview

Company Background and Development

Hypertherm was founded in 1968 by Richard Couch Jr., an engineer who aimed to develop advanced plasma cutting technology. With its headquarters in Hanover, New Hampshire, USA, the company has grown into a global leader in industrial cutting solutions, including plasma cutting, laser cutting, and waterjet cutting systems. Hypertherm’s commitment to innovation and quality has enabled the company to serve a wide range of industries, such as construction, shipbuilding, automotive manufacturing, and more.

Main Product Series and Features of Hypertherm Plasma Cutting Machines

Hypertherm offers a comprehensive range of plasma cutting machines designed to cater to various customer needs. Some of the main product series and their features include:

1. Hypertherm Powermax Series: The Powermax series of plasma cutting machines is designed for handheld and mechanized applications, offering versatility and ease of use. These systems are suitable for a wide range of cutting tasks, including metal fabrication, maintenance and repair, and on-site operations. The Powermax series features Hypertherm’s patented consumable technology, ensuring long consumable life, superior cut quality, and low operating costs.

2. Hypertherm MaxPro Series: The MaxPro series is designed for heavy-duty, high-capacity plasma cutting applications, providing exceptional performance and reliability. These machines are ideal for large fabrication shops, steel service centers, and industrial manufacturing facilities. The MaxPro series features advanced torch and consumable technologies, ensuring consistent and precise cutting performance.

3. Hypertherm XPR Series: The XPR series is Hypertherm’s latest generation of mechanized plasma cutting systems, offering enhanced cutting capabilities, improved cut quality, and increased productivity. These machines feature Hypertherm’s patented True Hole® technology, which delivers unmatched hole quality and dimensional accuracy. The XPR series also includes advanced process control features, such as automatic gas control and arc voltage height control, ensuring optimal cutting performance and reduced operator intervention.

Some key features of Hypertherm plasma cutting machines include:

1. Excellent cutting performance: Hypertherm equipment is known for its high cutting speed, accuracy, and a smaller heat-affected zone.

2. High efficiency: Hypertherm devices use advanced technology for efficient energy utilization and lower operating costs.

3. Easy maintenance: Hypertherm equipment is designed with ease of maintenance in mind, making it easy for users to perform daily maintenance and replace parts.

Comparison of ESAB and Hypertherm Plasma Cutting Machines

1. Technical performance comparison: Although both ESAB and Hypertherm plasma cutting machines perform well in terms of cutting speed and precision, Hypertherm is generally considered to have a higher cutting quality, especially on thinner metal materials.

2. Industry and application field comparison: Both ESAB and Hypertherm plasma cutting equipment are widely used in various industries, such as shipbuilding, automotive manufacturing, and construction. However, Hypertherm is usually more popular in heavy industries and high-precision cutting fields, while ESAB has a higher market share in light manufacturing.

3. Price and maintenance cost comparison: The prices of ESAB and Hypertherm plasma cutting equipment are similar, but with regard to maintenance costs, Hypertherm equipment is usually considered easier to maintain, and some models have lower consumable replacement costs.

4. Customer reviews and market reputation comparison: Both ESAB and Hypertherm have excellent reputations worldwide, and customers generally consider their equipment to be reliable and easy to operate. However, in the high-end market, Hypertherm equipment is often regarded as having a higher price-performance ratio.

How to Choose the Right Plasma Cutting Equipment Based on Your Needs

1. Technical Performance Comparison

When it comes to cutting mild steel, both ESAB and Hypertherm plasma cutting machines perform well in terms of cutting speed and precision. Hypertherm is generally considered to have a higher cutting quality, especially on thinner materials, due to its patented consumable technology and advanced process control features like FineCut, which ensure consistent and precise cutting performance. Additionally, Hypertherm’s plasma system utilizes a plasma arc that leads to clean and smooth cuts. On the other hand, ESAB machines are known for their reliability and high performance across a wide range of applications, making them a popular choice in various industries. Their cutting tips and plasma torch design contribute to efficient and precise cuts on mild steel.

2. Industry and Application Field Comparison

Both ESAB and Hypertherm plasma cutting equipment are widely used in various industries, such as shipbuilding, automotive manufacturing, and construction. However, Hypertherm is usually more popular in heavy industries and high-precision cutting fields, where the demand for superior cut quality and accuracy is higher. In contrast, ESAB has a higher market share in light manufacturing, where the focus is more on efficiency, versatility, and ease of use. The oxy fuel torch technology offered by ESAB allows for versatility in cutting various materials, including mild steel.

3. Price and Maintenance Cost Comparison

The prices of ESAB and Hypertherm plasma cutting equipment are similar, but with regard to maintenance costs, Hypertherm equipment is usually considered easier to maintain, and some models have lower consumable cost. This can be attributed to Hypertherm’s focus on designing machines with easy maintenance in mind and their patented consumable technology, which ensures longer consumable life. On the other hand, ESAB equipment is known for its durability and long service life, which can help offset maintenance costs over time. The duty cycle of both brands’ plasma cutters plays a significant role in determining their overall reliability and productivity.

4. Power Supply and System Features Comparison

ESAB and Hypertherm plasma cutters require a compatible power supply to operate effectively. Both brands offer a variety of power supply options to suit different needs and budgets. Hypertherm’s plasma system is known for its advanced features that help improve cut quality and precision, while ESAB’s plasma system also offers reliable performance with user-friendly controls and features.

5. Customer Reviews and Market Reputation Comparison

Both ESAB and Hypertherm have excellent reputations worldwide, and customers generally consider their equipment to be reliable and easy to operate. However, in the high-end market, Hypertherm equipment is often regarded as having a higher price-performance ratio, thanks to its superior cutting performance, advanced features, and lower maintenance costs. ESAB, on the other hand, is praised for its versatility, durability, and overall value, making it a popular choice for customers with diverse needs and budgets.

In summary, while both ESAB and Hypertherm offer high-quality plasma cutting machines, their strengths and advantages vary, making each brand more suitable for specific industries and applications.

When choosing a plasma cutting cnc machine, it is essential to consider factors such as technical performance, industry requirements, price, maintenance costs, and customer reviews to make an informed decision that best meets your needs.

Request A Free Quote

Have any questions about laser parts?

Don’t hesitate to contact us. Lasersourcing’s product specialists are very happy to help you and provide a variety of flexible and reliable solutions to help you solve various problems.

Tel

+86-15370952128

lasersourcing@hotmail.com

15370952128

+86-15370952128