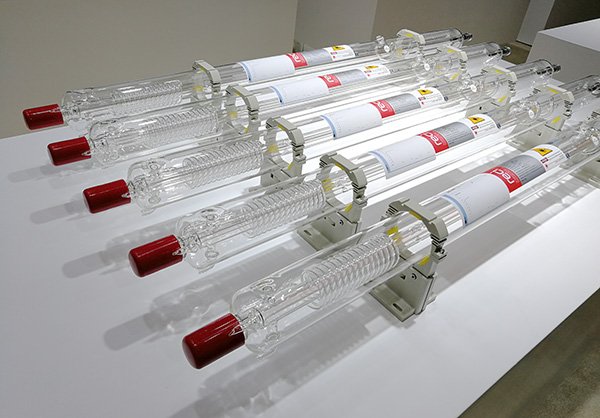

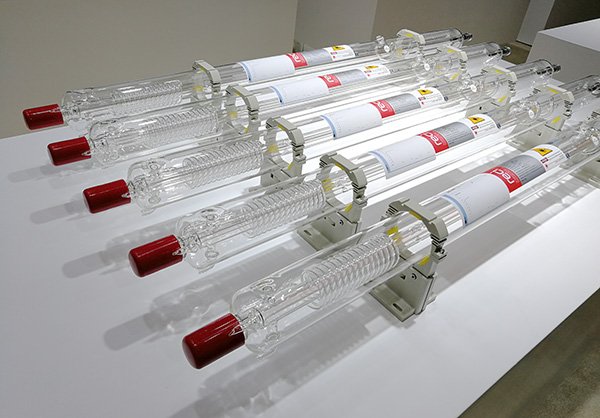

Co2 Laser Tube

The CO2 laser tube is an essential component in laser engraving and cutting machines, featuring various power ratings like 80W, 100W, and 130W. Notable manufacturers include Reci and EFR, known for their high-quality, reliable, and efficient laser tubes. These tubes produce a CO2 laser beam capable of cutting, marking, or engraving a wide range of materials with precision and speed. Both Reci and EFR offer excellent customer support and long-lasting performance, making them popular choices for businesses and hobbyists alike. Upgrade your laser system with a Reci or EFR CO2 laser tube to enhance productivity and achieve outstanding results.

Still not finding what you're looking for? Contact our consultants for more available products.

Full Co2 Laser Tube Solutions Supplier

We are a trusted supplier of Reci and EFR CO2 laser tubes, offering our customers numerous advantages when purchasing through us. Here are six reasons to choose us for your CO2 laser tube needs

Expertise

Our knowledgeable team can help you select the best Reci or EFR laser tube based on your specific requirements, ensuring optimal performance for your laser system.

Competitive Pricing

We source our laser tubes directly from Reci and EFR, ensuring our customers receive the most competitive prices without sacrificing quality.

Fast Delivery

Our dedicated customer support team is available to assist you with any questions or concerns you may have, ensuring a satisfying experience throughout the entire purchasing process and beyond.

Quality Assurance

As an authorized distributor, we guarantee genuine Reci and EFR products, ensuring top-notch performance and longevity for your laser system.

Flexible Payment Options

We provide a variety of payment methods to accommodate your preferences, making the purchasing process seamless and convenient.

After-Sales Support

For smaller orders, we utilize DHL and air freight, ensuring rapid delivery of your laser tubes. For larger orders, we offer cost-effective sea freight shipping options.

our experience help Boost your business

With extensive experience in the CO2 laser tube industry, our team has gained a deep understanding of Reci and EFR products. Our expertise enables us to provide tailored solutions, ensuring optimal performance and longevity for various laser applications. Our commitment to customer satisfaction, competitive pricing, and timely delivery has earned us a solid reputation as a reliable supplier of high-quality CO2 laser tubes, catering to diverse client needs across industries. Trust our seasoned professionals to guide you through the selection and purchasing process with confidence and ease.

Reliable Shipping Solution

Our shipping strategy prioritizes safety and efficiency, as CO2 laser tubes are fragile glass components. We take extra care in packaging and handling, utilizing robust materials to minimize breakage during transit.

Additionally, we insure all shipments against damage. In the unlikely event of a broken laser tube, rest assured that we’ll promptly arrange a replacement at no extra cost to you. Our commitment to customer satisfaction means you can trust us to deliver your laser tubes securely, mitigating potential risks and ensuring a smooth purchasing experience.

Quality Control System

We take quality seriously, which is why our CO2 laser lenses undergo strict quality control checks to ensure they arrive intact and ready to use. Our lenses are suitable for a wide range of applications, from 30W beauty laser machines to higher power hybrid cutting machines, and can cut, engrave, and mark a variety of materials including fabric, leather, acrylic, and foam.

Our commitment to quality control means that our customers can rely on our lenses to deliver precise and accurate results every time. Whether you’re working on a small-scale project or a large production run, our lenses are designed to meet your needs. With our rigorous quality control system, you can be confident that our lenses will arrive in perfect condition, ready for use in your laser machine.

Laser Nozzles

Amada Nozzle

Bystronic Nozzle

Mazak Nozzle

Mitsubishi Nozzle

DNE Nozzle

Nukon Nozzle

Ospri Nozzle

Hans Nozzle

Hankwang Nozzle

Laser Protective Windows

Adige BLM Windows

Amada Windows

Bystronic Windows

Eagle Windows

LVD Windows

Mazak Windows

Messer Windows

Mitsubishi Windows

Precitec Windows

Prima Windows

Raytools Windows

Salvagnini Windows

Trumpf Windows

WSX Windows

Welding Windows

DNE Windows

Hankwang Windows

Hans Windows

Laser Ceramic Part

Bystronic Ceramic

DNE Ceramic

Nukon Ceramic

Hans Ceramic

Precitec Ceramic

PENTA Ceramic

IPG Ceramic

Raytools Ceramic

Ospri Ceramic

Friendess Ceramic

Trumpf Ceramic

High Yag Ceramic

Hankwang Ceramic

Laser Head

Raytools Laser Head

WSX Laser Head

Plasma Consumables

Hypertherm Consumables

Kjellberg Consumables

Thermal Dynamics Consumables

Lincoln Consumables

ESAB Consumable

Trafimet Consumable

What are the different types of CO2 laser tubes?

CO2 laser tubes can be broadly categorized into two types based on their construction and cooling mechanism:

- Glass CO2 Laser Tubes: These are the most common type of CO2 laser tubes used in laser engraving and cutting machines. They feature a sealed glass tube filled with a gas mixture, primarily carbon dioxide, helium, and nitrogen. The electrical discharge within the tube excites the gas molecules, generating the laser beam. Glass CO2 laser tubes are further divided into two categories:

a. Water-cooled: These tubes require an external water chiller to dissipate the heat generated during operation, ensuring optimal performance and longevity. They are commonly found in higher power machines (40W and above).

b. Air-cooled: These tubes use fans or natural convection to cool the system. Typically found in lower power machines (below 40W), air-cooled tubes are less efficient but require less maintenance compared to water-cooled tubes.

- Metal CO2 Laser Tubes: These tubes utilize a metal casing filled with a CO2 gas mixture. Metal tubes generally offer higher beam quality, faster response times, and longer lifespans compared to glass tubes. They also have a higher initial cost but lower overall operating costs. Metal CO2 laser tubes are commonly used in industrial applications where high precision and performance are required.

Both types of CO2 laser tubes have their advantages and disadvantages, making them suitable for different applications and industries.

Which is the best CO2 laser tube?

It’s difficult to pinpoint the “best” CO2 laser tube, as the ideal choice depends on your specific requirements, intended applications, and budget. However, some well-known and reputable CO2 laser tube manufacturers include:

Reci: Renowned for their high-quality, long-lasting laser tubes, Reci offers a wide range of power options suitable for various applications. Their tubes are popular among both businesses and hobbyists.

EFR: Another respected manufacturer, EFR produces reliable and efficient CO2 laser tubes. They provide excellent customer support and consistently deliver solid performance across their product line.

SPT (Shanghai SPT Laser Technology): SPT is known for producing cost-effective and good-quality laser tubes. They offer a range of power options to cater to diverse needs.

Yongli: Yongli offers a wide range of CO2 laser tubes that are known for their durability, stability, and affordable prices.

When selecting the best CO2 laser tube for your needs, consider factors such as power, cooling mechanism, tube lifespan, and beam quality. It’s essential to match the tube’s specifications with your laser system’s requirements and your intended applications. Additionally, seek recommendations from industry peers, read reviews, and consult with experts to make an informed decision.

What is a laser tube?

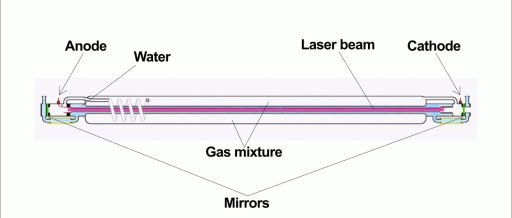

A laser tube is a critical component of a laser system that generates a laser beam through the process of stimulated emission. Laser tubes are available in various types, including CO2 laser tubes, which are commonly used in laser engraving and cutting machines.

In a CO2 laser tube, a sealed glass or metal tube is filled with a gas mixture primarily composed of carbon dioxide, helium, and nitrogen, along with smaller amounts of other gases. When electricity is applied to the tube, it excites the gas molecules, causing them to emit photons. These photons then bounce back and forth between mirrors inside the tube, amplifying the light through stimulated emission. The amplified light eventually exits through a partially transparent mirror as a focused laser beam.

What is the most effective CO2 laser?

The term “most effective” CO2 laser depends on the specific application and requirements of the user. The effectiveness of a CO2 laser can be measured by factors like precision, cutting or engraving speed, power, and reliability.

When considering a CO2 laser system, it’s essential to determine the materials you will be working with, the thickness of the materials, your desired output quality, and your budget. These factors will help you decide which CO2 laser is the most effective for your particular needs.

Some popular and reputable CO2 laser system manufacturers include:

Epilog Laser: Renowned for their high-quality laser engraving and cutting systems, Epilog offers a range of models with various power options and bed sizes suitable for different applications.

Trotec Laser: Trotec is known for their fast, precise, and reliable laser systems, catering to a wide variety of industries and applications, from small businesses to large-scale production.

Universal Laser Systems (ULS): ULS produces versatile and user-friendly laser systems suitable for various applications, including cutting, engraving, and marking.

Boss Laser: Boss Laser offers affordable and reliable laser systems, providing options for both hobbyists and businesses.

To find the most effective CO2 laser for your needs, research different models, consult with industry experts, and read reviews from users with similar requirements. Remember that the most effective CO2 laser will be the one that best meets your specific needs and offers the best balance of performance, quality, and cost.

Are all CO2 lasers the same?

No, not all CO2 lasers are the same. There are several factors that differentiate CO2 lasers, making them suitable for different applications, industries, and budgets. Some of these factors include:

Power: CO2 lasers come in various power ratings, typically ranging from 10W to over 150W. The power output determines the cutting and engraving capabilities of the laser system, affecting factors such as cutting speed, material thickness, and engraving depth.

Laser Tube Type: CO2 lasers can have either glass or metal laser tubes. Glass tubes are more common and usually more affordable, while metal tubes offer higher beam quality, faster response times, and longer lifespans but at a higher initial cost.

Cooling Mechanism: CO2 lasers can be either water-cooled or air-cooled. Water-cooled lasers require an external water chiller to dissipate heat generated during operation, while air-cooled lasers use fans or natural convection. The choice between the two depends on factors like power requirements, operating environment, and maintenance preferences.

Beam Quality: The quality of the laser beam affects the precision and accuracy of the engraving or cutting process. Higher-quality beams are essential for intricate designs or applications requiring fine detail.

System Components: Different CO2 lasers may have varying components, such as mirrors, lenses, power supplies, and controllers, which can affect the overall performance, reliability, and ease of use.

Manufacturer: CO2 lasers are produced by various manufacturers, each with their own design, build quality, and support services. Some well-known CO2 laser manufacturers include Reci, EFR, Epilog, Trotec, and Universal Laser Systems.

When selecting a CO2 laser system, it is crucial to consider these factors and match them with your specific needs, budget, and intended applications. Not all CO2 lasers are the same, and the right choice depends on your unique requirements.

Is CO2 laser the same as fractional CO2 laser?

No, a CO2 laser and a fractional CO2 laser are not the same, although they both utilize carbon dioxide as the primary lasing medium. The key difference lies in the way the laser energy is delivered to the target area.

A CO2 laser emits a continuous or pulsed laser beam, producing a consistent, uninterrupted output. It is widely used in various applications such as cutting, engraving, and marking materials like wood, acrylic, and fabric. CO2 lasers are also employed in medical procedures like skin resurfacing, where the laser removes thin layers of skin with high precision.

A fractional CO2 laser, on the other hand, is a specific type of CO2 laser used for skin resurfacing and rejuvenation. It delivers laser energy in a pixelated pattern, creating microscopic treatment zones (also called microthermal treatment zones or MTZs) on the skin while leaving the surrounding tissue untouched. This fractional approach allows for faster healing and less downtime compared to traditional CO2 laser resurfacing, as it only targets a fraction of the skin surface.

In summary, while both CO2 lasers and fractional CO2 lasers utilize carbon dioxide as their lasing medium, they differ in their energy delivery methods and applications. Fractional CO2 lasers are specifically designed for skin resurfacing and rejuvenation, providing a more controlled and targeted treatment.

What is Class 4 CO2 laser?

A Class 4 CO2 laser refers to a high-powered CO2 laser system that is classified under the highest safety class designated by the international laser safety standards (such as IEC 60825 and ANSI Z136). Class 4 lasers are considered the most hazardous due to their high power output, which typically ranges from 500 milliwatts (0.5 watts) and higher. CO2 lasers in this class can cause severe injury or damage to the skin, eyes, and materials if not used correctly and with appropriate safety measures in place.

Class 4 CO2 lasers are commonly used in industrial applications, such as cutting, engraving, and marking various materials, including wood, acrylic, fabric, glass, and metal (with the assistance of an appropriate laser source). Due to their high power, they can achieve faster cutting and engraving speeds and handle thicker materials compared to lower-class lasers.

How many hours does a CO2 laser tube last?

The lifespan of a CO2 laser tube depends on its type, quality, and usage conditions. Generally, a CO2 laser tube can last anywhere between 1,000 to 10,000 hours or more.

How long does an 80W laser tube last?

The lifespan of an 80W laser tube depends on factors such as the type of laser tube, its quality, and the usage conditions. In general, an 80W laser tube can last anywhere between 1,000 to 10,000 hours

What material is CO2 laser used for ?

CO2 lasers are versatile and can be used for processing various materials. Some common applications include:

Cutting: CO2 lasers are used for cutting materials such as wood, acrylic, plastics, fabrics, leather, rubber, and thin metals.

Engraving: They are popular for engraving on materials like wood, glass, stone, ceramics, plastics, and some metals.

Marking: CO2 lasers can mark materials like anodized aluminum, coated metals, ceramics, and some plastics.

Etching: They can be used for etching patterns or designs onto glass, ceramics, and other materials.

Drilling: CO2 lasers can drill small holes in materials like plastics, ceramics, and thin metals.

Overall, CO2 lasers are widely used in industries such as manufacturing, aerospace, automotive, electronics, packaging, and textiles due to their ability to process a wide range of materials with precision and speed.

How does CO2 laser tube work?

A CO2 laser tube works by amplifying light through the process of stimulated emission, creating a concentrated beam of infrared light. The main components of a CO2 laser tube include an enclosed gas mixture, electrodes, and mirrors. Here’s a step-by-step explanation of how a CO2 laser tube works:

Gas mixture: The laser tube contains a mixture of gases, primarily carbon dioxide (CO2), along with smaller amounts of nitrogen (N2) and helium (He). The CO2 molecules act as the active lasing medium.

Electrical discharge: An electric current is passed through the gas mixture using electrodes. This electrical discharge excites the gas molecules, especially the nitrogen molecules, which then transfer their energy to the CO2 molecules.

Population inversion: The energy transfer causes a population inversion in the CO2 molecules, meaning that there are more molecules in an excited state than in a lower-energy state. This is essential for laser action to occur.

Stimulated emission: When the excited CO2 molecules return to their lower-energy state, they release photons in the process. If these photons encounter other excited CO2 molecules, they can stimulate the release of additional photons, all with the same wavelength and phase. This is called stimulated emission.

Amplification: The laser tube contains mirrors at each end – one fully reflective and the other partially reflective. The photons generated through stimulated emission bounce back and forth between these mirrors, stimulating more emissions and causing the light to amplify.

Laser beam: As the light continues to amplify, some of it passes through the partially reflective mirror, creating a highly concentrated and coherent beam of infrared light. This is the laser beam, which can then be focused and directed for various applications such as cutting, engraving, and marking.

In summary, a CO2 laser tube works by using electrical energy to excite gas molecules, creating a population inversion that leads to stimulated emission and amplification of light, ultimately producing a concentrated laser beam.

What are CO2 laser tubes filled with?

CO2 laser tubes are filled with a mixture of gases, primarily carbon dioxide (CO2), along with smaller amounts of nitrogen (N2) and helium (He).

How does CO2 laser principle work?

The CO2 laser principle works by using electrical energy to excite gas molecules, creating a population inversion that leads to stimulated emission and amplification of light, ultimately producing a concentrated and coherent laser beam.

How does CO2 laser work in simple words?

A CO2 laser works by using electricity to excite gas molecules in a sealed tube, creating an intense beam of infrared light that can be focused and directed for various applications like cutting, engraving, and marking.

What is a CO2 laser engraver used for?

A CO2 laser engraver is used for engraving various materials such as wood, glass, stone, ceramics, plastics, and some metals. Applications include creating designs, logos, text, or patterns on these materials for personalization or identification purposes.

Do CO2 lasers need gas?

Yes, Co2 Laser Need gas, usually it can be air because during the operation of a CO2 laser engraver, the laser head may need a flow of gas to blow away debris and smoke created by the engraving process. This gas flow is typically provided by an air compressor or a dedicated gas source.

The gas flow helps to clear the engraving area and prevent the accumulation of debris, which can interfere with the laser beam and affect the quality of the engraving. It also helps to prevent the material being engraved from overheating and melting, which can cause damage to the material and affect the accuracy of the engraving.

In addition to debris removal and cooling, the gas flow can also have other functions depending on the specific application. For example, it can help to create a more precise and focused laser beam, or it can be used to improve the contrast of the engraving by creating a color contrast between the material and the debris.

What temperature should a CO2 laser tube be?

The optimal water temperature for a CO2 laser tube during operation is typically between 15 and 25 degrees Celsius (59-77 degrees Fahrenheit). It’s important to maintain a consistent water temperature within this range to ensure effective cooling of the laser tube and prevent overheating, which can damage the tube and affect laser performance. Some CO2 laser systems may have specific recommendations for water temperature, so it’s important to refer to the manufacturer’s instructions for specific guidelines.

What causes a CO2 laser tube to crack?

There are several factors that can cause a CO2 laser tube to crack, including:

Thermal shock: Rapid temperature changes can cause the laser tube to expand or contract too quickly, leading to cracking.

Overexcitation of the gas mixture: If the electrical power supplied to the laser tube is too high, the gas mixture inside can be overexcited, causing pressure buildup and potential tube failure.

Voltage spikes: Electrical voltage spikes can occur if the laser system is not properly grounded, leading to damage and potential tube failure.

Physical damage: Accidents or mishandling of the laser tube, such as dropping or hitting it, can cause cracks or other types of damage.

Age and wear: Over time, the laser tube may weaken or become damaged due to repeated use and aging.

It’s important to handle the laser tube carefully and maintain proper electrical and cooling conditions to prevent cracking and extend the life of the tube. It’s also important to follow the manufacturer’s guidelines for laser tube replacement and maintenance to ensure optimal performance and safety.

What is the pressure inside a CO2 laser tube?

The pressure inside a CO2 laser tube typically ranges between 3 and 20 torr, with the optimal pressure depending on the specific model and application. The pressure is maintained by the gas flow rate and the temperature of the laser tube.

Request A Free Quote

Have any questions about laser parts?

Don’t hesitate to contact us. Lasersourcing’s product specialists are very happy to help you and provide a variety of flexible and reliable solutions to help you solve various problems.

Tel

+86-15370952128

lasersourcing@hotmail.com

15370952128

+86-15370952128