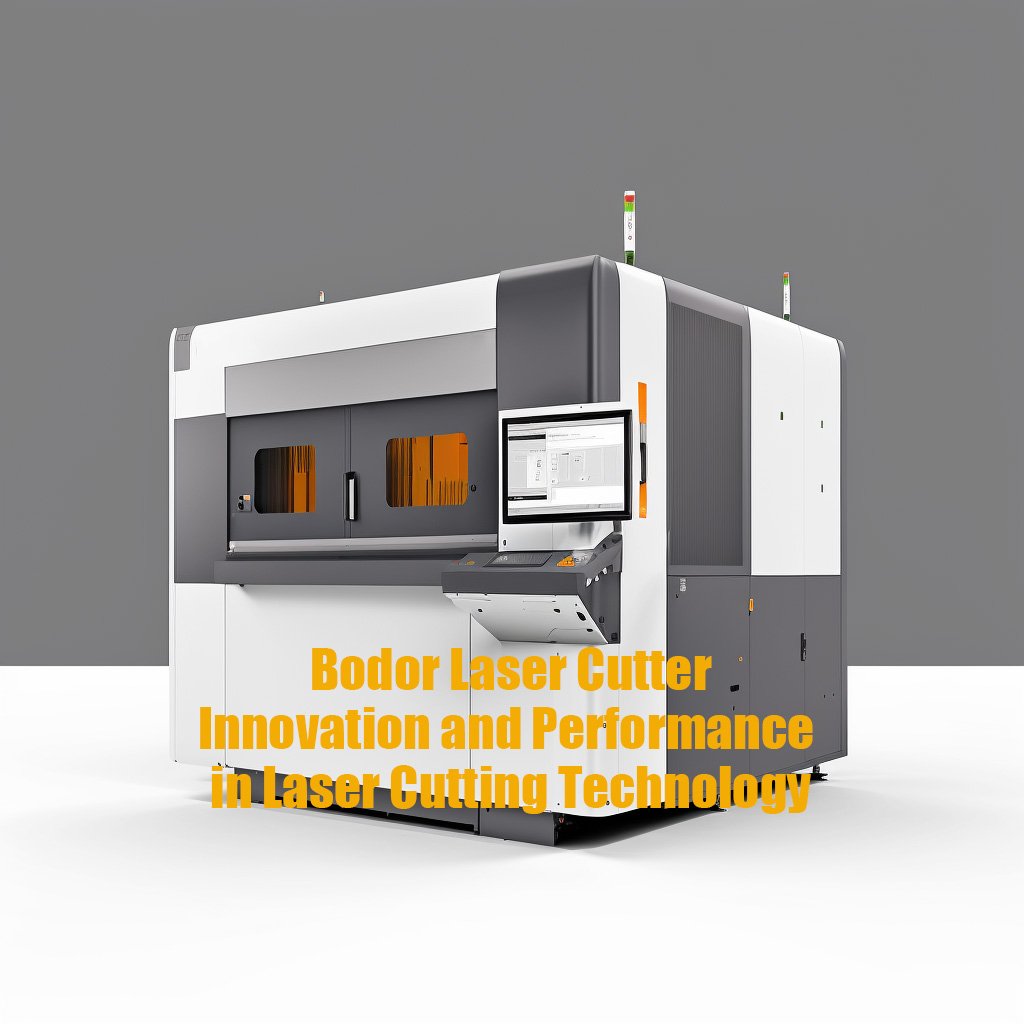

Bodor Laser Cutter: Innovation and Performance in Laser Cutting Technology

I. Introduction

Bodor Laser, a renowned company established in 2008, specializes in the research, development, and production of high-quality laser cutting machines. With a strong commitment to innovation, Bodor has become a prominent name in the laser cutting industry, offering a wide range of laser cutters suitable for various applications. This essay aims to provide a comprehensive understanding of Bodor laser cutters, exploring their types, key features, advantages, applications, and future prospects.

II. Types of Bodor Laser Cutters

A. Fiber laser cutters

Fiber laser cutters, one of the most popular types of Bodor laser cutters, utilize a doped optical fiber as the active medium for generating a highly concentrated laser beam. These machines are known for their high precision, fast cutting speeds, and energy efficiency, making them ideal for cutting various metals, including stainless steel, carbon steel, and aluminum.

B. CO2 laser cutters

Bodor CO2 laser cutters use a gas mixture, primarily composed of carbon dioxide, as the active medium to generate the laser beam. They are commonly employed for cutting non-metallic materials, such as acrylic, wood, and leather. With their versatility and high power output, CO2 laser cutters are widely used in signage, woodworking, and packaging industries.

C. Tube and pipe laser cutters

Specifically designed for processing tubes and pipes, these laser cutters offer precision cutting and profiling of various shapes and sizes. With their advanced control systems and cutting head technology, Bodor tube and pipe laser cutters can handle complex cutting tasks, such as hole punching, beveling, and mitering, with ease and accuracy.

D. High-power laser cutters

These laser cutters are equipped with high-power laser sources, typically ranging from 6 kW to 20 kW, to handle thick and dense materials. Bodor high-power laser cutters are designed for heavy-duty cutting applications in industries such as shipbuilding, heavy machinery, and aerospace.

E. 3D laser cutters

Bodor 3D laser cutters enable cutting and processing of three-dimensional objects with intricate geometries. These machines are particularly useful in the automotive, aerospace, and medical industries, where precision and flexibility are paramount.

III. Key Features and Technologies in Bodor Laser Cutters

A. Advanced control systems

Bodor laser cutters are equipped with advanced CNC (Computer Numerical Control) systems, which ensure precise and consistent cutting performance. These control systems coordinate the movement of the cutting head and adjust the laser’s parameters, such as power, speed, and focus, in real-time to optimize the cutting process.

B. High-quality laser sources

Bodor collaborates with leading laser source manufacturers, such as IPG Photonics and nLIGHT, to integrate high-quality laser sources into their machines. These reliable and efficient laser sources provide stable power output, ensuring long-lasting performance and reduced operating costs.

C. Cutting-edge autofocus cutting head

The autofocus cutting head is a crucial component of Bodor laser cutters. It features an advanced lens system that automatically adjusts the focus to accommodate different material thicknesses and maintain optimal cutting performance. This technology not only improves the cutting quality but also reduces the need for manual adjustments and maintenance.

D. Efficient cooling systems

Bodor laser cutters incorporate efficient cooling systems to regulate the temperature of the laser source and cutting head, preventing overheating and ensuring consistent cutting performance. These cooling systems are designed to be low-maintenance and energy-efficient, contributing to the overall cost-effectiveness of the machines.

E. User-friendly software

Bodor’s proprietary software is designed to be intuitive and user-friendly, allowing operators to easily set up cutting jobs and monitor the machine’s performance. The software also offers advanced features, such as nesting and automatic path planning, which help optimize material usage and reduce waste.

IV. Advantages of Using Bodor Laser Cutters

A. Precision and accuracy

Bodor laser cutters are known for their exceptional precision and accuracy, with tolerances as tight as ±0.05mm. This level of precision enables the production of intricate designs and complex geometries with ease, resulting in high-quality finished products.

B. Enhanced productivity and efficiency

With automated CNC control systems, fast cutting speeds, and advanced software features, Bodor laser cutters significantly increase productivity and efficiency. These machines can handle large-scale production runs with minimal operator intervention, reducing labor costs and turnaround times.

C. Reduced material waste

The precision cutting capabilities of Bodor laser cutters result in minimal material waste, as they can accurately follow complex cutting paths and make tight cuts with minimal kerf width. This not only reduces material costs but also contributes to a more sustainable manufacturing process.

D. Versatility and flexibility

Bodor laser cutters are designed to handle a wide range of materials and applications, from cutting thin sheets of metal to processing thick plates and 3D objects. Their versatility allows manufacturers to adapt to changing market demands and expand their product offerings with ease.

E. Ease of operation and maintenance

Bodor laser cutters are designed with user-friendly interfaces and software, making them easy to operate even for those with limited experience. Additionally, the machines require minimal maintenance, thanks to their advanced cooling systems and durable components.

V. Applications of Bodor Laser Cutters

A. Manufacturing and metalworking

Bodor laser cutters are widely used in various manufacturing and metalworking applications, including sheet metal fabrication, metal furniture production, and machine component manufacturing.

B. Automotive and aerospace industries

With their high precision and flexibility, Bodor laser cutters are extensively used in the automotive and aerospace industries to produce intricate components, such as engine parts, chassis components, and interior trim pieces.

C. Construction and infrastructure

In the construction and infrastructure sectors, Bodor laser cutters are employed to process structural steel, pipes, and tubes used in building frames, bridges, and other structures.

D. Energy and utility sector

Bodor laser cutters play a vital role in the energy and utility sector, where they are used to produce components for wind turbines, solar panels, and electrical transmission equipment.

E. Medical and healthcare equipment

The medical and healthcare industries benefit from the precision and accuracy of Bodor laser cutters in the production of surgical instruments, implants, and other medical devices.

F. Art, design, and signage

Bodor laser cutters are also utilized in the art and design sector, where they are used to create intricate sculptures, architectural models, and custom signage.

VI. Comparing Bodor Laser Cutters to Competitors

A. Market position and reputation

Bodor has established itself as a leading manufacturer of laser cutting machines, known for its commitment to innovation and quality. Its strong market position and reputation attest to the performance and reliability of its products.

B. Technological innovation

Bodor continuously invests in research and development, ensuring that its laser cutters incorporate the latest technologies and features. This commitment to innovation sets Bodor apart from its competitors and allows it to maintain a competitive edge in the market.

C. Price and affordability

While offering advanced features and performance, Bodor laser cutters are competitively priced, making them an attractive option for businesses looking to invest in laser cutting technology without breaking the bank.

D. Customer service and support

Bodor provides comprehensive customer service and support, including training, technical assistance, and maintenance services. This ensures that customers can maximize the performance and lifespan of their laser cutters.

VII.Future Prospects for Bodor Laser Cutters

A. Technological advancements and innovations

As the laser cutting industry continues to evolve, Bodor is expected to remain at the forefront of technological advancements and innovations. The company’s dedication to research and development will likely lead to the introduction of new features, improved performance, and greater efficiency in future laser cutter models.

B. Expansion into new markets and industries

As Bodor laser cutters continue to gain recognition for their performance and reliability, the company is poised to expand into new markets and industries. This growth will likely be driven by the increasing demand for advanced manufacturing solutions in emerging sectors, such as electronics, renewable energy, and additive manufacturing.

C. Integration with Industry 4.0 and IoT

The integration of Bodor laser cutters with Industry 4.0 and IoT (Internet of Things) technologies is expected to further enhance their capabilities and performance. Real-time data collection, remote monitoring, and predictive maintenance are just a few of the potential benefits that these technologies can bring to laser cutting operations.

D. Sustainability and eco-friendly initiatives

As environmental concerns become increasingly important, Bodor is likely to continue developing sustainable and eco-friendly solutions in its laser cutting machines. Energy efficiency, reduced material waste, and the use of eco-friendly materials and processes will likely become focal points in the company’s future product offerings.

VIII. Conclusion

Bodor laser cutters have established themselves as innovative and reliable solutions in the laser cutting industry, offering a wide range of machines tailored to various applications and materials. With their advanced features, high precision, and efficiency, Bodor laser cutters provide businesses with a competitive edge and the ability to meet ever-changing market demands. As the company continues to invest in research and development, it is expected to remain at the forefront of technological advancements in the laser cutting industry. By embracing the opportunities presented by Industry 4.0, IoT, and sustainability initiatives, Bodor will likely continue to shape the future of laser cutting technology and maintain its position as a market leader.