A Comprehensive Guide to the Hypertherm HPR400XD Plasma System

I. Introduction

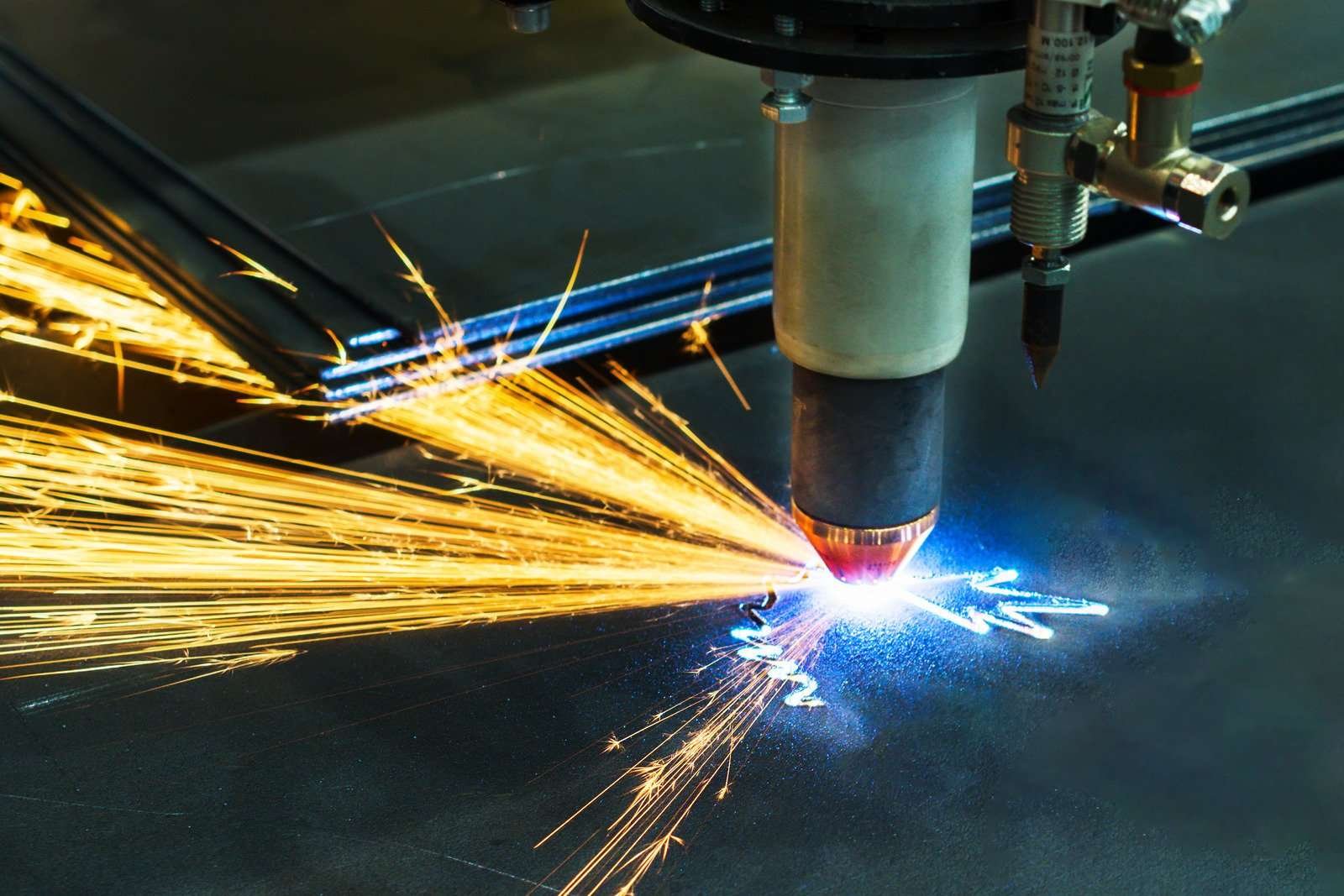

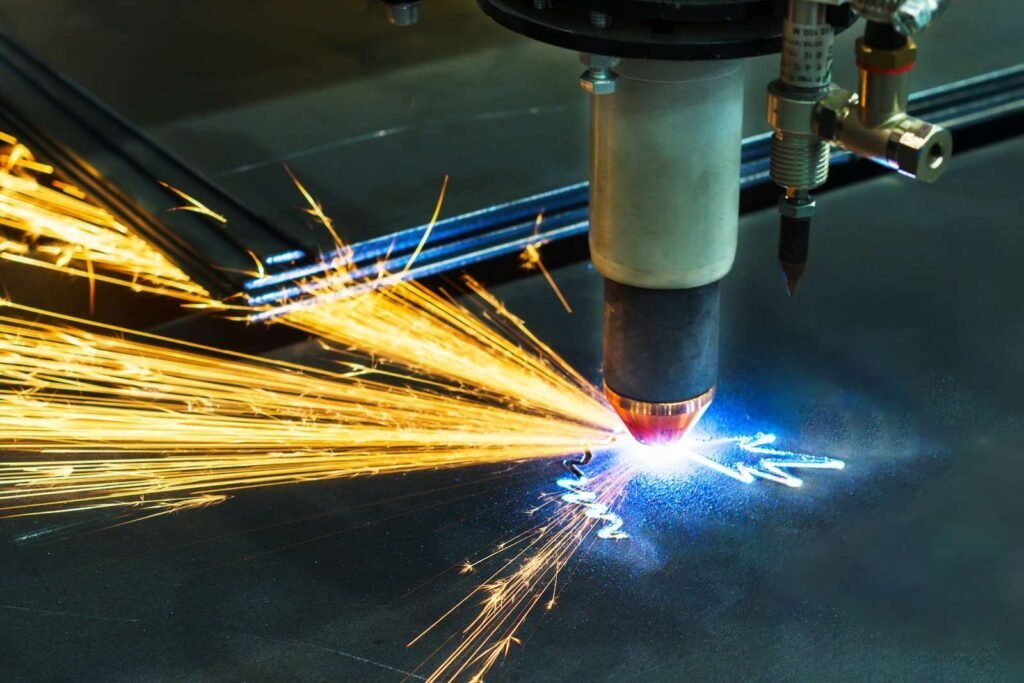

1.Explanation of the Hypertherm HPR400XD plasma system

The Hypertherm HPR400XD is a high-performance plasma system used in a wide range of cutting applications. This article will provide an overview of the system, its capabilities, and what sets it apart from other plasma systems on the market.

2.Importance of using the right plasma system for cutting needs

In the world of metal fabrication, choosing the right plasma system is critical to achieving the desired results. With the Hypertherm HPR400XD, you can be confident in your ability to cut a wide range of materials with precision and efficiency. Whether you’re a professional fabricator or a DIY enthusiast, the HPR400XD is an excellent choice for your cutting needs.

II. What is the Hyperformance HPR400XD Plasma System?

1.Overview of the HPR400XD plasma system

The Hyperformance HPR400XD plasma system is a high-performance cutting system that is designed to handle a wide range of cutting needs. It is manufactured by Hypertherm, a leading provider of plasma cutting technology.

2.Key features and benefits

1.Patented True Hole technology that produces holes with superior edge quality and minimal taper

2.Advanced HyDefinition technology that delivers cleaner, sharper, and more consistent cuts

3.Long consumable life and low operating costs due to the system’s advanced technology and design

4.Enhanced piercing capabilities for faster and more efficient cutting

Compatibility with a range of materials, including mild steel, stainless steel, aluminum, and more

3.Cutting capabilities and thickness

The HPR400XD plasma system is capable of cutting through a range of thicknesses, depending on the specific material being cut. For example:

Mild steel: up to 2-1/4 inches (57 mm)

Stainless steel: up to 2 inches (51 mm)

Aluminum: up to 1-1/2 inches (38 mm)

III. What Can the HPR400XD Cut?

1.Examples of materials that can be cut using the HPR400XD

The HPR400XD plasma system is a powerful cutting machine that can handle a wide range of materials. Some of the materials it can cut include:

Mild steel

Stainless steel

Aluminum

Copper

Brass

Titanium

2.Advantages of using the HPR400XD for cutting

With its advanced technology and high-quality components, the HPR400XD is capable of cutting these materials with exceptional precision and speed. This makes it an ideal choice for a variety of industries, including manufacturing, construction, and automotive.

The HPR400XD also offers several advantages over other cutting methods. For example, it can produce cleaner cuts with less material distortion and beveling, resulting in less material waste and improved efficiency. Additionally, its high cutting speed and capacity allow for increased productivity and reduced downtime.

IV. What is a HPR400XD Starter Kit?

1.Overview of starter kit options

The HPR400XD is a powerful plasma cutting system, but getting started with it can be daunting. That’s where a starter kit comes in. These kits are designed to give you everything you need to get up and running with your HPR400XD, from consumables to safety gear.

2.Components included in a typical starter kit

Here’s an overview of what you can expect to find in a typical HPR400XD starter kit:

Nozzles: The HPR400XD uses a variety of nozzles, each optimized for a specific type of cutting. Starter kits will typically include a range of nozzles to get you started.

Electrodes: The electrodes are an essential part of the plasma cutting process, as they help generate the arc that cuts the metal. Like nozzles, electrodes will wear out over time and need to be replaced. A starter kit will typically include a set of electrodes.

Swirl rings: Swirl rings help to control the flow of gas through the torch, which in turn affects the shape and quality of the cut. Starter kits will typically include a few swirl rings.

Shield: The shield is an important safety component that helps protect the operator from the plasma arc. A starter kit will typically include a shield.

Machine torch and/or hand torch: Depending on the starter kit you choose, you may get a machine torch, a hand torch, or both.

Consumables case: A consumables case is a convenient way to keep all your HPR400XD consumables organized and in one place. Many starter kits include a case.

Safety gear: Plasma cutting can be dangerous work, so it’s important to wear the right safety gear. Starter kits may include items like gloves, safety glasses, and ear protection.

V. What Makes Hypertherm Different?

Hypertherm has been a leader in the plasma cutting industry for over 50 years, and the HPR400XD is just one example of their commitment to excellence. Here are some of the factors that set Hypertherm apart:

Innovation

Hypertherm invests heavily in research and development, constantly seeking to improve their products and stay ahead of the curve in the industry. This dedication to innovation is reflected in the many patents they hold for plasma cutting technology.

Quality

Hypertherm is known for the high quality of their products, which are built to last and deliver consistent, accurate performance. The HPR400XD is no exception, with features like the patented Coaxial-assist™ jet technology that provide superior cut quality and faster cutting speeds.

Support

In addition to offering top-notch products, Hypertherm provides excellent customer support and service. They have a global network of authorized distributors and service centers, as well as online resources like manuals, videos, and forums to help customers get the most out of their plasma cutting systems.

Sustainability

Hypertherm is committed to reducing their environmental impact through sustainable practices and initiatives. The HPR400XD is designed with energy efficiency in mind, and Hypertherm has a goal to be carbon neutral by 2030.

VI. HPR400XD Price

1.Average cost of the HPR400XD plasma system

The average cost of the Hypertherm HPR400XD plasma system is around $100,000 to $150,000 depending on the configuration and options selected.

The cost may vary based on the vendor, location, and additional services provided with the purchase.

2.Comparison with other plasma systems in its class

When comparing the HPR400XD to other plasma systems in its class, it may be higher priced than some of its competitors. However, it is also known for its high quality, precision cutting, and durability, which may justify the cost for some users.

In the long run, investing in a high-quality plasma system like the HPR400XD may actually save money by reducing downtime, improving cut quality, and requiring less frequent replacement of consumables.

VII.HPR130XD HPR260XD HPR400XD Consumables

Nozzles:

220193 (30A)

220554 (50A)

220188 (80A)

220374 (100A)

220182 (130A)

220354 (200A)

220439 (260A)

Electrodes:

220192 (30A)

220552 (50A)

220187 (80A)

220181 (130A)

220352 (200A)

220435 (260A)

Swirl Rings:

220180 (30A)

220553 (50A)

220179 (80A-130A)

220353 (200A)

220436 (260A)

Retaining Caps:

220313 (30A-50A)

220176 (80A-130A)

220355 (200A)

220433 (260A)

Shields:

220194 (30A)

220555 (50A)

220189 (80A)

220183 (130A)

220356 (200A)

220440 (260A)

Shield Caps:

220173 (30A-130A)

220398 (200A-260A)

Water Tubes:

220340