A Comprehensive Guide to Fiber Laser Cutter Parts: Everything You Need to Know

I. Introduction

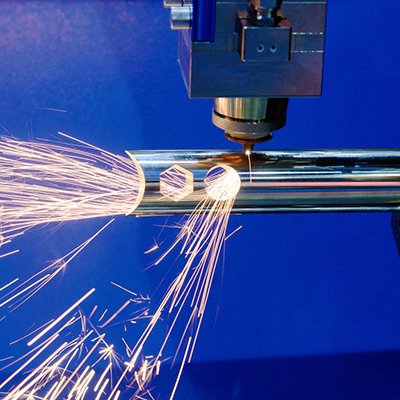

Fiber laser cutting technology is a game-changer in the world of industrial cutting. It has revolutionized the way businesses cut metal and other materials, providing faster and more accurate results than ever before. But to achieve optimal performance with a fiber laser cutting machine, it is crucial to understand the different components that make up the system, especially the fiber laser parts.

Fiber laser parts play a critical role in the performance of a cutting machine. They are responsible for generating the laser beam that cuts through materials and ensure the precision and accuracy of the cut. Without high-quality fiber laser parts, a cutting machine may experience decreased performance and efficiency, leading to longer processing times and increased costs.

In this blog post, we aim to provide a comprehensive guide to fiber laser parts. We will cover the different types of fiber laser parts, their functions, and how to maintain them for optimal performance. We will also discuss common issues that may arise with fiber laser parts and provide tips for selecting the best parts for your cutting machine. Whether you are a new or experienced user of fiber laser cutting technology, this guide will provide you with the knowledge and tools necessary to get the most out of your cutting machine.

II. Types of Fiber Laser Parts

Fiber laser cutting machines are made up of different components that work together to produce high-quality cuts. Here are the main types of fiber laser parts and their functions:

Fiber Laser Source:

Generates the laser beam used for cutting

Composed of a laser diode, fiber optic cable, and optical resonator

Determines the quality and efficiency of the cutting process

Laser Cutting Head:

Contains the lens that focuses the laser beam onto the material being cut

Includes a nozzle that delivers gas to help remove molten metal from the cut

Quality and precision of the laser cutting head are essential for accurate cutting and reducing the risk of damage to the machine

Laser Chiller:

Cools the laser source and other components of the machine to prevent overheating and prolong the life of the system

Circulates water or another cooling medium through the machine

Laser Beam Delivery System:

Includes the fiber optic cable that connects the fiber laser source to the laser cutting head

Quality of the fiber optic cable is essential for delivering a stable and consistent laser beam to the cutting head

Controller:

Manages the movement of the cutting head, adjusts laser power, and controls other parameters of the cutting process

Quality and precision of the controller are crucial for achieving accurate cuts and maximizing efficiency

Cutting Nozzles:

Deliver gas to the cutting area to help remove molten metal and improve cutting quality

Available in different sizes and materials depending on the specific application and material being cut

Ceramic Parts:

Used in the laser cutting head to help protect the lens and other components from heat and debris

Made of high-temperature resistant materials to withstand the harsh environment of laser cutting

Protective Windows:

Installed in the laser cutting head to protect the lens from debris and splatter

Made of durable materials that can withstand the heat and pressure of the cutting process

Lens:

Focuses the laser beam onto the material being cut

Available in different materials and configurations depending on the specific application and material being cut

Each of these fiber laser parts is essential for the efficient and accurate cutting process of a fiber laser cutting machine. Choosing high-quality parts from reputable suppliers and maintaining them regularly can help ensure the optimal performance of the machine.

III. Common Fiber Laser Part Issues

Despite the high quality of fiber laser parts, issues can arise that can affect the performance of the machine. Here are some of the common issues that can occur with fiber laser parts:

Laser Beam Instability:

The laser beam may become unstable, resulting in uneven cuts or decreased efficiency

Can be caused by issues with the fiber laser source, fiber optic cable, or laser cutting head

Nozzle Clogging:

The nozzle that delivers gas to the cutting head may become clogged with debris, resulting in reduced cutting quality or even damage to the machine

Cooling System Failure:

If the laser chiller fails, the machine may overheat, resulting in decreased performance or even damage to the system

Controller Malfunction:

The controller may experience issues, resulting in inaccurate cuts or other performance problems

To identify and diagnose these issues, it is important to regularly inspect the fiber laser parts and monitor the performance of the machine. Here are some steps for addressing and resolving common problems with fiber laser parts:

Laser Beam Instability:

Check the fiber optic cable for any damage or misalignment

If the issue persists, contact a qualified technician to inspect the fiber laser source or the laser cutting head

Nozzle Clogging:

Inspect the nozzle regularly and clean it if necessary

Consider using a higher-quality nozzle that is less prone to clogging

Cooling System Failure:

Regularly monitor the temperature of the machine and check the chiller for any issues or malfunctions

Consider using a backup cooling system to prevent overheating in case of chiller failure

Controller Malfunction:

Check the controller for any error messages or malfunctions

If necessary, contact a qualified technician to repair or replace the controller

By promptly identifying and addressing these common issues with fiber laser parts, businesses can prevent performance issues and maximize the efficiency and longevity of their cutting machines.

IV. Best Practices for Maintaining Fiber Laser Parts

Regular maintenance is essential for ensuring the optimal performance of a fiber laser cutting machine. By following these best practices for maintaining fiber laser parts, businesses can prevent issues and prolong the life of their cutting machine:

Follow a maintenance schedule:

Establish a regular maintenance schedule for each type of fiber laser part

This schedule should include routine inspections, cleaning, and replacement of parts as needed

Keep the machine clean:

Regularly clean the machine, including the laser cutting head and nozzle, to prevent debris buildup and maintain cutting quality

Use a soft cloth or compressed air to remove dust and debris from the machine

Monitor the laser beam:

Regularly monitor the laser beam for any signs of instability, such as fluctuations in power or uneven cuts

If necessary, inspect the fiber laser source, fiber optic cable, and laser cutting head for any issues

Maintain the cooling system:

Regularly monitor the cooling system and replace the water or other cooling medium as needed

Keep the chiller clean and free of debris to prevent overheating and prolong the life of the machine

Use high-quality parts:

Use only high-quality fiber laser parts from reputable suppliers

Cheap or low-quality parts can result in decreased performance and increased maintenance needs

By following these best practices for maintaining fiber laser parts, businesses can ensure the optimal performance and longevity of their cutting machine. Regular maintenance can prevent issues, increase efficiency, and reduce costs over the long term.

V. Factors to Consider When Choosing Fiber Laser Parts

Choosing the right fiber laser parts is essential for the optimal performance of a cutting machine. Here are some key factors to consider when selecting fiber laser parts:

Quality:

Choose high-quality fiber laser parts from reputable suppliers to ensure the longevity and optimal performance of the machine

Low-quality parts can result in decreased efficiency and increased maintenance needs

Compatibility:

Ensure that the fiber laser parts are compatible with your specific cutting machine

Different machines require different types of fiber laser parts, so it is important to choose parts that are designed for your machine

Price:

While cost is an important consideration, it should not be the only factor

Choosing high-quality fiber laser parts may cost more upfront, but it can result in long-term savings by reducing maintenance needs and improving efficiency

Brand Reputation:

Consider the reputation of the brand when selecting fiber laser parts

Choose brands that are well-known and trusted in the industry

Technical Support:

Look for suppliers that offer technical support and assistance with installation and maintenance of the parts

This can help ensure the optimal performance of the machine and reduce downtime

When comparing different types and brands of fiber laser parts, it is important to consider these factors to make an informed decision. By choosing the right fiber laser parts, businesses can ensure the optimal performance and longevity of their cutting machine.

It is also important to choose a reputable supplier for high-quality fiber laser parts. Look for suppliers that have a track record of providing reliable and high-quality parts and that offer technical support and assistance with installation and maintenance. Choosing a reputable supplier can help ensure that the fiber laser parts are of the highest quality and are designed to meet the specific needs of the cutting machine.

VI. Conclusion

Fiber laser parts are an essential component of a fiber laser cutting machine, and they play a crucial role in the efficiency, precision, and accuracy of the machine. In this blog post, we have discussed the different types of fiber laser parts, their functions, common issues that can arise, and best practices for maintenance and choosing the right parts.

It is important to prioritize maintenance and quality when it comes to fiber laser parts. Regular maintenance can prevent issues and prolong the life of the cutting machine, while choosing high-quality parts can improve efficiency and reduce long-term costs.

Key takeaways from this blog post include the importance of regularly monitoring the laser beam, keeping the machine clean, maintaining the cooling system, choosing high-quality parts from reputable suppliers, and establishing a regular maintenance schedule.

In conclusion, investing in high-quality fiber laser parts and prioritizing maintenance can help ensure the optimal performance and longevity of a cutting machine. We encourage readers to take these best practices into consideration and prioritize the quality and maintenance of their fiber laser parts. By doing so, businesses can maximize the efficiency and profitability of their cutting operations.