Top 18 Plasma Cutting Equipment Brands 2023

I.Introduction

Brief overview of plasma cutting

Plasma cutting is a process that cuts through electrically conductive materials by means of an accelerated jet of hot plasma. It’s most commonly used to cut through steel, aluminum, brass, and copper, but can also cut through other conductive metals. Discuss the basic science behind the process, including the use of an electric arc and gas to create plasma.

Importance and impact of plasma cutting technology

Plasma cutting technology has revolutionized the metalworking industry. It offers significant advantages over traditional cutting methods, including cleaner cuts, higher cutting speeds, and the ability to cut through thicker materials. This technology has improved the efficiency and quality of metalwork across a range of industries, from automotive to construction to manufacturing.

Overview of the 18 brands that will be discussed

BINZEL, CASTOLIN, CEA, CEBORA, COMMERCY, ESAB, GYS, HYPERTHERM, KALIBURN, KOIKE, KJELLBERG, LINCOLN, OERLIKON, OTC, THERMAL DYNAMICS, TRAFIMET, Miller Electric, and Panasonic.

II. Understanding Plasma Cutting Equipment

How plasma cutting works

Plasma cutting works by sending an electric arc through a gas that is passing through a constricted opening. This electrical arc ionizes some of the gas molecules, turning them into plasma. The plasma is hot enough to cut metal and moves fast enough to blow molten metal away from the cut. The nature of the plasma allows it to cut metal with much more precision and less waste than traditional cutting methods.

Key components and features of typical plasma cutting equipment

The main components of a plasma cutter are the power supply, the arc starting circuit, and the torch. The power supply regulates the machine’s current, converting a high voltage, low current circuit into a low voltage, high current one. The arc starting circuit creates a small spark inside the torch to initiate the plasma arc. The torch provides proper alignment and cooling of the consumables. The consumables, comprised of the electrode, swirl ring, and nozzle, are the parts that initiate the plasma arc and shape it. Some plasma cutters also include a shield to protect the consumables from excessive heat and molten metal.

Plasma cutters come with a variety of features, depending on the model. Some include automatic settings and controls, allowing for easier operation and more precise cuts. Others have high-frequency starting systems for a more reliable ignition. Additional features may include built-in air compressors, drag-cutting technology, and advanced cooling systems.

It’s important to note that the specific components and features can vary widely depending on the brand and model of the plasma cutter. As we move on to discuss the top 19 brands in plasma cutting equipment, we’ll look at the unique features and innovations each one brings to the table.

III. Top 18 Plasma Cutting Equipment Brands of 2023

1.Binzel

Brief History and Headquarters Location:

Founded by Adolf Binzel in 1945, Binzel began in Germany as a manufacturer of cutting torches for both handheld and mechanized applications. Over the decades, the company has expanded its product offerings to include a wide range of welding and cutting tools, such as plasma cutters. Its commitment to quality and innovation has enabled Binzel to become a global leader in the manufacturing of plasma cutting equipment by 2023. The company’s headquarters is located in Buseck, Germany.

Market Coverage:

Binzel’s products are sold in over 80 countries, reflecting its broad market coverage. The company has a significant presence across Europe, America, Asia, and Oceania due to its various subsidiaries in these regions. This international presence allows Binzel to cater to diverse industries worldwide, providing them with top-notch plasma cutting solutions.

Famous Equipment Models and Their Features:

One of the most well-known product series from Binzel is the ABICOR BINZEL range of plasma cutters. For instance, the ABIPLAS CUT 70 is a popular choice due to its compact design, impressive cut quality, and ease of use. The machine boasts an excellent power-to-weight ratio and is suitable for both professional and semi-professional use.

Another notable model, the ABIPLAS CUT 130, is renowned for its high cutting speed and efficiency. This powerful machine can handle thick materials and is frequently used in heavy industries like shipbuilding, construction, and manufacturing. Both models reflect Binzel’s dedication to producing robust, high-performing plasma cutting tools.

2.CASTOLIN

Brief History and Headquarters Location:

Castolin Eutectic, also known simply as Castolin, was founded in 1906 by Jean-Pierre Wasserman who discovered a way to weld cast iron at low temperatures. This led to the birth of the Eutectic Welding process, which has been central to Castolin’s operations ever since. The company has grown over the decades, expanding its expertise to include a variety of welding, brazing, and coating technologies, including plasma cutting. By 2023, Castolin has established itself as a leading global provider of such equipment. The headquarters of Castolin is in Lausanne, Switzerland.

Market Coverage:

Castolin has a wide market presence, with its products being available in over 100 countries across the world. The company has more than 20 affiliated companies and a large network of distributors and service centers, ensuring its reach to customers in various industries and regions. Castolin’s broad range of solutions caters to sectors such as energy, oil and gas, cement, and the manufacturing industry, among others.

Famous Equipment Models and Their Features:

In the realm of plasma cutting, Castolin is renowned for its CastoPlasmaCut series. The CastoPlasmaCut 40i, for example, is a portable device known for its flexibility and precision. It can cut through various materials with a thickness of up to 10mm, making it suitable for light to medium industrial applications.

Another notable product is the CastoPlasmaCut 120i, which is valued for its power and cutting speed. Designed for more demanding applications, this machine can cut materials as thick as 45mm. Both models demonstrate Castolin’s commitment to delivering high-performing and reliable plasma cutting solutions.

3.CEA

Brief History and Headquarters Location:

CEA Spa was established in 1950 in Italy. The company started as a manufacturer of welding machines and grew to become one of the world’s leading companies in the design and production of industrial welding and plasma cutting systems. As of 2023, CEA is renowned for its high-quality, innovative products that cater to a wide range of sectors. The company’s headquarters is located in Citta di Castello, Perugia, Italy.

Market Coverage:

CEA has an extensive global presence, selling its products in over 75 countries. With numerous international subsidiaries and a wide distribution network, CEA is able to cater to various industries including automotive, construction, and manufacturing, among others.

Famous Equipment Models and Their Features:

In terms of plasma cutting equipment, CEA is known for its PLASMA CUT series. The PLASMA CUT 2060/T, for instance, is a powerful and flexible machine. It is notable for its high cutting speed and the ability to cut through materials as thick as 25mm. The PLASMA CUT 4065/T, on the other hand, is a heavy-duty plasma cutter capable of handling materials as thick as 40mm. It is known for its excellent cutting precision and energy efficiency. Both models demonstrate CEA’s dedication to providing robust, reliable, and versatile plasma cutting solutions.

4.CEBORA

Brief History and Headquarters Location:

CEBORA was founded in 1954 in Bologna, Italy. Initially, the company produced charging regulators for batteries and welders for the automotive industry. Over time, CEBORA expanded its product range to include a variety of welding and cutting systems, becoming well-known for its plasma cutting equipment. As of 2023, CEBORA is recognized globally for its high-quality, innovative products. The company’s headquarters remains in Bologna, Italy.

Market Coverage:

CEBORA has a global reach, with its products being sold in over 150 countries worldwide. The company has an extensive distribution network, allowing it to cater to various industries such as automotive repair, manufacturing, construction, and many more.

Famous Equipment Models and Their Features:

CEBORA is renowned for its high-quality plasma cutting machines. One such model is the Plasma Sound PC 10048/T. Known for its compact size, portability, and precision cutting ability, this machine is suitable for both industrial and non-industrial applications. Another popular model, the AUTO Plasma 6061/T, is designed for automation. It is appreciated for its high cutting speed, capability to handle thick materials, and excellent energy efficiency. These models demonstrate CEBORA’s commitment to quality and innovation in the plasma cutting industry.

5.COMMERCY

Brief History and Headquarters Location:

Commercy Soudure was founded in 1953 in Commercy, France. Starting as a small local company, it has grown over the years to become a leading manufacturer of welding and cutting equipment, including plasma cutters. As of 2023, Commercy Soudure is a recognized brand in the field of welding and cutting technology. The company’s headquarters are located in Commercy, France.

Market Coverage:

Commercy Soudure’s products are distributed worldwide, catering to a diverse range of industries such as construction, manufacturing, automotive, and more. The company has an extensive distribution network across Europe and other parts of the world, enabling it to serve customers from different regions effectively.

Famous Equipment Models and Their Features:

In the realm of plasma cutting, Commercy Soudure is known for its Oerlikon CUTLINE series. The Oerlikon CUTLINE C40 is appreciated for its portability, easy handling, and ability to cut materials up to 15mm thick, making it suitable for both professional and semi-professional applications.

Another notable model is the Oerlikon CUTLINE C70, which offers higher cutting power and can handle materials as thick as 30mm. It’s also known for its user-friendly design and energy efficiency. Both these models showcase Commercy Soudure’s commitment to providing high-performance, reliable plasma cutting tools.

6.ESAB

Brief History and Headquarters Location:

Founded by Oscar Kjellberg in 1904, ESAB (Electric Welding Limited) is one of the oldest and most respected names in the welding and cutting equipment industry. It was Kjellberg who invented the world’s first coated welding electrode, marking the beginning of ESAB’s journey in innovative welding solutions. Over the years, ESAB expanded its product line to include plasma cutting systems, earning a reputation for quality and innovation. As of 2023, ESAB continues to be a leading global manufacturer of welding and cutting equipment. The company’s headquarters is located in Gothenburg, Sweden.

Market Coverage:

ESAB has a wide global presence, distributing its products in nearly 80 countries across Europe, North America, South America, Asia, and Africa. With a wide distribution network and a large number of subsidiaries worldwide, ESAB can cater to a diverse range of industries including construction, manufacturing, automotive, and many more.

Famous Equipment Models and Their Features:

In the field of plasma cutting, ESAB’s Cutmaster series stands out. The Cutmaster 40 is a compact, portable unit known for its high power output and reliability. It’s able to cut metal up to 15mm thick and is suited for both light and heavy-duty applications.

The Cutmaster 60i, another popular model, offers increased cutting capacity (up to 20mm) and faster cutting speeds, while maintaining the portability and user-friendly design that the series is known for. Both models illustrate ESAB’s commitment to innovation and providing high-quality, reliable plasma cutting solutions.

7.GYS

Brief History and Headquarters Location:

GYS was founded in 1964 by Guy Marquette in Laval, France. Starting as a small family business, GYS expanded over the years and has become a significant player in the design and manufacture of welding machines, battery chargers, and car body repair equipment, including plasma cutting systems. As of 2023, GYS continues to be recognized worldwide for its high-quality products and commitment to innovation. The company’s headquarters are located in Laval, France.

Market Coverage:

GYS has a strong global presence, distributing its products in more than 100 countries across all continents. With several subsidiaries and a wide distribution network, GYS has the ability to cater to various industries including automotive, manufacturing, construction, and more.

Famous Equipment Models and Their Features:

In terms of plasma cutting, GYS is well known for its Cutter series. The PLASMA CUTTER 31F is a compact, portable machine that can cut through materials up to 10mm thick, making it suitable for light industrial and automotive repair applications.

On the other hand, the PLASMA CUTTER 85 TRI is a powerful machine designed for more demanding applications. It is capable of cutting materials as thick as 30mm, and is appreciated for its high cutting speed and accuracy. These models showcase GYS’s commitment to providing robust, versatile, and reliable plasma cutting solutions.

8.HYPERTHERM

Brief History and Headquarters Location:

Hypertherm was founded in 1968 by Richard W. Couch, Jr. and Robert Dean in Hanover, New Hampshire, USA. The company was the first to introduce water injection plasma cutting, a significant breakthrough in the industry. Over the years, Hypertherm has maintained its innovative spirit and dedication to quality, expanding its product line to include a wide range of high-performance plasma cutters. By 2023, Hypertherm is a global leader in plasma cutting technology. The company’s headquarters is still located in Hanover, New Hampshire, USA.

Market Coverage:

Hypertherm’s products are available in more than 60 countries, ensuring broad market coverage. Its comprehensive international presence allows Hypertherm to cater to diverse industries globally, providing them with advanced plasma cutting solutions.

Famous Equipment Models and Their Features:

Hypertherm is renowned for its Powermax series of plasma cutters. For instance, the Powermax45 XP is known for its portability, ease of use, and the ability to cut materials up to 16mm thick. It’s designed for both hand-held and mechanized applications, offering versatility to the user.

The Powermax85, on the other hand, offers more power and a greater cut capacity of up to 25mm, suitable for heavy-duty industrial applications. Both models demonstrate Hypertherm’s commitment to producing powerful, versatile, and high-performing plasma cutting tools.

9.KALIBURN

Brief History and Headquarters Location:

KALIBURN, previously known as InnerLogic, was founded in 1985 in the USA. Over the years, it established itself as a leader in precision plasma cutting systems. The company became a part of the ESAB brand in 2011, further reinforcing its position in the global market. As of 2023, KALIBURN continues to be a reputable brand known for its advanced cutting solutions. The company’s headquarters are located in Florence, South Carolina, USA.

Market Coverage:

As a part of the ESAB family, KALIBURN’s products are distributed worldwide, catering to a variety of sectors such as heavy fabrication, automotive, manufacturing, and construction. With ESAB’s extensive global network, KALIBURN’s cutting solutions are accessible in various regions across the globe.

Famous Equipment Models and Their Features:

KALIBURN is known for its Spirit II series of high precision plasma cutting systems. The Spirit II 150a, for instance, stands out for its cutting precision and ability to handle materials up to 20mm thick, making it suitable for both light and heavy industrial applications.

Another notable model, the Spirit II 400a, offers more power and a larger cutting capacity, capable of cutting materials as thick as 50mm. This model is designed for heavy-duty applications requiring high cutting speeds and precision. Both models illustrate KALIBURN’s commitment to delivering powerful, accurate, and reliable plasma cutting solutions.

10.KOIKE

Brief History and Headquarters Location:

KOIKE was established in 1918 in Tokyo, Japan, initially as a gas welding and cutting equipment manufacturer. Over the years, the company has grown and expanded its product portfolio to include arc welding and plasma cutting equipment. As of 2023, KOIKE is a global leader in cutting and welding solutions. The company’s headquarters are still located in Tokyo, Japan.

Market Coverage:

KOIKE has a global footprint with its products being sold in over 100 countries worldwide. Through an extensive network of subsidiaries and distributors, KOIKE is able to reach a wide variety of industries including construction, manufacturing, shipbuilding, and automotive, among others.

Famous Equipment Models and Their Features:

KOIKE is known for its superior plasma cutting systems. The Super400P, for example, is a heavy-duty machine known for its high cutting speed and the ability to cut materials up to 50mm thick. It’s suitable for large-scale industrial applications.

Another noteworthy model is the Handy Auto Plus, a compact, portable cutter designed for high precision hand cutting. It can handle materials up to 30mm thick, offering a good balance of power, precision, and portability. These models demonstrate KOIKE’s commitment to providing innovative, reliable, and high-performing plasma cutting solutions.

11.KJELLBERG

Brief History and Headquarters Location:

Kjellberg Finsterwalde was established in 1922 in Finsterwalde, Germany. The company is the oldest manufacturer of plasma cutting technology in the world and is known for its continued innovations in the field. As of 2023, Kjellberg is a leading global supplier of plasma cutting and welding equipment. The company’s headquarters are located in Finsterwalde, Germany.

Market Coverage:

Kjellberg’s products are distributed globally, allowing it to serve a wide range of industries including automotive, shipbuilding, construction, and manufacturing among others. The company’s extensive distribution network ensures its cutting solutions are accessible to customers all over the world.

Famous Equipment Models and Their Features:

Kjellberg is known for its HiFocus series of high-precision plasma cutting systems. For example, the HiFocus 130 is praised for its cutting precision and ability to handle materials up to 40mm thick, making it suitable for diverse industrial applications.

Another model, the HiFocus 360i, offers increased power and a higher cutting capacity (up to 80mm), making it suitable for heavy-duty applications. Both models showcase Kjellberg’s dedication to providing powerful, accurate, and reliable plasma cutting solutions.

12.LINCOLN

Brief History and Headquarters Location:

Lincoln Electric was founded in 1895 by John C. Lincoln in Cleveland, Ohio, USA. Starting as a manufacturer of electric motors, the company expanded into the design and production of welding equipment, and later into plasma cutting systems. By 2023, Lincoln Electric is a globally recognized leader in the design, development, and manufacture of arc welding products, robotic arc-welding systems, plasma, and oxyfuel cutting equipment. The company’s headquarters are still located in Cleveland, Ohio, USA.

Market Coverage:

Lincoln Electric’s products are available in more than 160 countries, ensuring comprehensive market coverage. Its wide global presence allows Lincoln Electric to cater to a multitude of industries worldwide, providing them with advanced welding and cutting solutions.

Famous Equipment Models and Their Features:

In the realm of plasma cutting, Lincoln Electric is known for its Tomahawk series. The Tomahawk 375 Air, for instance, is appreciated for its compact design, portability, and the ability to cut materials up to 10mm thick. It is suitable for both home hobbyists and light industrial applications.

The Tomahawk 1000, on the other hand, is a more powerful model that can cut materials up to 31.75mm thick. This model is designed for more demanding industrial applications and is known for its high cutting speed, precision, and reliability. These models showcase Lincoln Electric’s commitment to providing robust, versatile, and reliable plasma cutting solutions.

13.MILLER

Brief History and Headquarters Location:

Miller Electric Manufacturing Co. was established in 1929 by Niels Miller in Appleton, Wisconsin, USA. Over the years, the company has grown to be a world leader in the manufacturing of arc welding and cutting equipment. By 2023, Miller Electric is a globally recognized brand known for its innovative, high-quality products. The company’s headquarters remain in Appleton, Wisconsin, USA.

Market Coverage:

Miller’s products are distributed in over 100 countries worldwide, giving the brand substantial global reach. With its extensive distribution network, Miller caters to a variety of industries, including construction, manufacturing, automotive, shipbuilding, and many more.

Famous Equipment Models and Their Features:

In the field of plasma cutting, Miller is renowned for its Spectrum series. The Spectrum 375 X-TREME, for instance, stands out for its portability, easy setup, and the ability to cut materials up to 9.5mm thick, making it ideal for light-duty applications.

The Spectrum 875, on the other hand, is a high-performance cutter suitable for more demanding industrial applications. It can cut materials as thick as 22mm, and is appreciated for its high cutting speed and precision. Both models exemplify Miller’s dedication to providing powerful, reliable, and easy-to-use plasma cutting tools.

14.OERLIKON

Brief History and Headquarters Location:

Oerlikon was established in 1906 in Pfäffikon, Switzerland. Over the years, the company has grown and diversified its offerings, becoming a global technology group providing high-tech solutions for various industries. In its Welding division, Oerlikon produces a broad range of welding and cutting solutions, including plasma cutting systems. As of 2023, Oerlikon’s headquarters are located in Pfäffikon, Switzerland.

Market Coverage:

Oerlikon has a global footprint with operations in over 30 countries. Its welding and cutting equipment is used across various industries such as automotive, aviation, energy, and mechanical and plant engineering. This extensive coverage allows Oerlikon to serve a wide array of customers around the world.

Famous Equipment Models and Their Features:

In terms of plasma cutting, Oerlikon’s CUTLINE series is well-recognized. The CUTLINE T 35 model is known for its compact design and user-friendly interface, capable of cutting materials up to 15mm thick. It’s an ideal solution for small businesses and personal use.

For heavy-duty industrial applications, the CUTLINE T 70 model offers more power and a larger cutting capacity (up to 25mm), and is known for its robustness and high cutting speed. Both models demonstrate Oerlikon’s commitment to producing versatile, powerful, and high-performing plasma cutting tools.

15.OTC

Brief History and Headquarters Location:

OTC DAIHEN was established as a division of Osaka Transformer Company (OTC) in 1919 in Japan. The company quickly gained a reputation for quality, particularly in the field of welding and cutting equipment. In 1980, it adopted the name DAIHEN to represent the brand globally. As of 2023, OTC DAIHEN continues to be a global leader in the welding and cutting industry. The company’s headquarters are located in Osaka, Japan.

Market Coverage:

With its products distributed in over 50 countries, OTC DAIHEN maintains a broad global market presence. Its comprehensive international distribution network allows OTC DAIHEN to serve a diverse range of industries, including automotive, manufacturing, construction, and more.

Famous Equipment Models and Their Features:

In the realm of plasma cutting, OTC DAIHEN is known for its AIC series. The AIC-1600, for instance, is a high-performance plasma cutter that can handle materials up to 35mm thick. It is designed for heavy-duty industrial applications, offering high cutting speed and precision.

Another noteworthy model, the AIC-1500, while slightly less powerful, provides a balanced combination of performance and affordability, capable of cutting materials up to 30mm thick. Both models showcase OTC DAIHEN’s commitment to delivering powerful, accurate, and reliable plasma cutting solutions.

16.THERMAL DYNAMICS

Brief History and Headquarters Location:

Thermal Dynamics was established in 1957 in the USA. The company pioneered the modern plasma electrode, making significant contributions to the wider acceptance and use of plasma cutting technology across industries. In 1993, Thermal Dynamics was acquired by Victor Technologies (now part of ESAB), enhancing its global reach and product offerings. As of 2023, the company’s headquarters are located in St. Louis, Missouri, USA.

Market Coverage:

As part of ESAB, Thermal Dynamics’ products are available globally, ensuring comprehensive market coverage. Its extensive distribution network allows Thermal Dynamics to cater to diverse industries worldwide, providing them with advanced plasma cutting solutions.

Famous Equipment Models and Their Features:

Thermal Dynamics is known for its Cutmaster series of plasma cutters. The Cutmaster 40, for example, is renowned for its portability, easy setup, and ability to cut materials up to 16mm thick. It is designed for light to medium-duty applications.

On the other hand, the Cutmaster 60i offers a more powerful solution for heavy-duty industrial applications. This model can cut materials as thick as 38mm, demonstrating impressive cutting speed and precision. Both models illustrate Thermal Dynamics’ commitment to producing powerful, efficient, and reliable plasma cutting tools.

17.TRAFIMET

Brief History and Headquarters Location:

Trafimet was founded in 1975 in Italy as a manufacturer of torches for welding and plasma cutting machines. Over the years, Trafimet has gained a reputation for innovation, quality, and reliability. As of 2023, the company’s headquarters are located in Castegnato, Italy.

Market Coverage:

Trafimet’s products are distributed in over 70 countries worldwide, demonstrating its broad market coverage. The company serves various industries including shipbuilding, construction, automotive, and manufacturing among others.

Famous Equipment Models and Their Features:

Trafimet is known for its robust and reliable plasma cutting tools. A noteworthy model is the Ergocut series. For instance, the Ergocut S45 is popular for its high cutting speed, efficiency, and the ability to cut materials up to 15mm thick. This model is designed for light to medium industrial applications.

For heavier duty applications, the Ergocut S105 stands out. This model has the capacity to cut materials as thick as 35mm and is known for its durability and power. These models illustrate Trafimet’s commitment to providing powerful and reliable plasma cutting solutions.

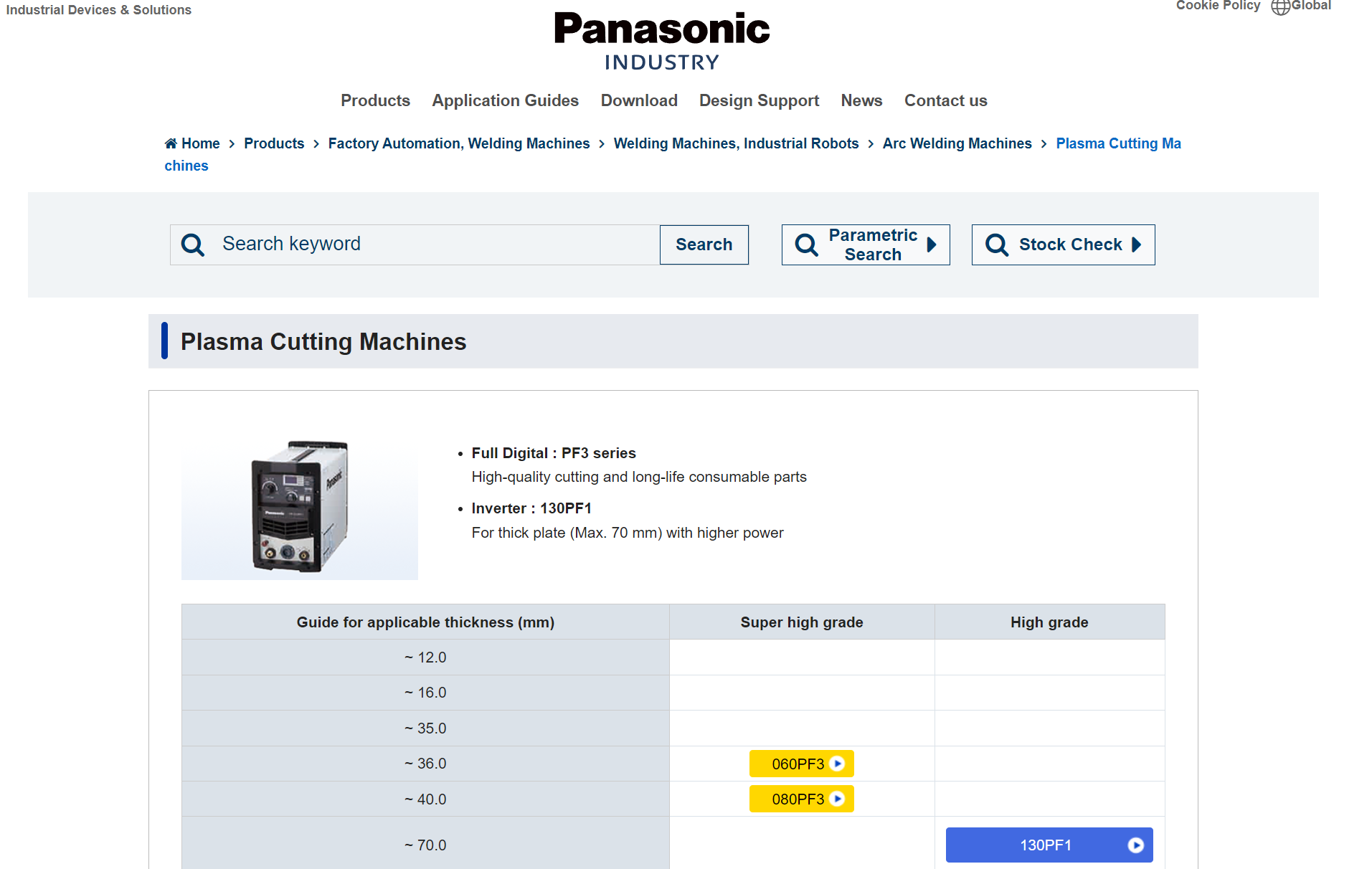

18.Panasonic

Brief History and Headquarters Location:

Panasonic was established in 1918 by Konosuke Matsushita in Osaka, Japan. While the company is known for a wide range of electronic products, it has also developed a strong presence in the field of welding and cutting equipment through its Panasonic Welding Systems division. As of 2023, Panasonic’s headquarters remain in Osaka, Japan.

Market Coverage:

Panasonic’s welding and cutting equipment is distributed globally, ensuring comprehensive market coverage. Through its extensive international distribution network, Panasonic serves a diverse range of industries including automotive, shipbuilding, infrastructure, and more.

Famous Equipment Models and Their Features:

In the realm of plasma cutting, Panasonic has a well-respected line of products. For instance, the P-80 handheld plasma cutter is well-known for its excellent cutting performance, high-speed operation, and the ability to cut materials up to 40mm thick. It’s suitable for a wide range of applications from light-duty tasks to heavy industrial operations.

Another standout model is the Panasonic X-series, such as the X-45, which is praised for its ease of use, compact design, and the ability to cut materials up to 15mm thick. Both models demonstrate Panasonic’s commitment to providing powerful, reliable, and versatile plasma cutting tools.

IV.Brief comparison of each brands in terms of key features, price points, and industry reputation

1. BINZEL: Known for their high-quality plasma cutters and torches, BINZEL offers products with extensive cutting thickness and precise cutting. It is suitable for customers seeking reliability and versatility. BINZEL’s products fall in the mid-high price range.

2. CASTOLIN: CASTOLIN specializes in cutting equipment and cnc cutting machines, featuring good plasma cutters for a variety of metal thicknesses. Products fall in the mid-price range, suitable for customers looking for a balance between affordability and quality.

3. CEA: This Italian brand focuses on innovation in the welding and plasma cutting industry. They offer a range of products including cnc plasma cutters and laser cutting machines. CEA products are ideal for customers who prioritize technology advancements, with a higher initial investment.

4. CEBORA: With a competitive advantage in the automobile sector, CEBORA offers automotive cutting solutions and good plasma cutter options at affordable price points, appealing to customers seeking value for money and efficiency.

5. COMMERCY: COMMERCY provides heavy-duty cutting solutions, focusing on oxyfuel cutting machines and plasma cutting systems. The brand is ideal for industrial use and is known for its durability and reliability.

6. ESAB: A global leader in welding and cutting equipment, ESAB offers top-quality plasma cutting machines and plasma torches. With a wide range of products, they cater to different material thickness and cutting requirements. ESAB products are perfect for customers seeking high performance and quality regardless of the price.

7. GYS: Known for their quality and innovation, GYS offers excellent cnc cutting machines, plasma cutters, and cutting materials. Their products are ideal for customers who value innovation and forward-thinking technology.

8. HYPERTHERM: HYPERTHERM is a world-renowned brand in the plasma cutting and CNC machining industry. Their top-quality plasma cutting systems, including the Powermax series, are known for their excellent cut quality, reliability, and durability. HYPERTHERM is suitable for professionals and businesses looking for high performance and a solid industry reputation.

9. KALIBURN: Specializing in precision plasma cutting, KALIBURN offers products with perfect cut quality for thin metal and sheet metal applications. Their products are ideal for customers looking for precision and attention to detail in cutting materials.

10. KOIKE: KOIKE provides top-notch cnc plasma cutting machines and equipment. Known for their portability, these plasma cutters cater to various industries and are perfect for customers confident in their cnc operation skills.

11. KJELLBERG: Known for their precise cutting equipment and torches, KJELLBERG offers a range of cnc plasma cutting machines and best plasma cutters. Their expertise in cutting metals and technology makes them a perfect choice for skilled operators looking for precision equipment.

12. LINCOLN ELECTRIC: A well-known brand, LINCOLN ELECTRIC offers a wide range of welding and cutting equipment, including plasma cutters and cnc machines. With competitive pricing, LINCOLN ELECTRIC is a suitable option for beginners to professionals who prioritize affordability without compromising quality.

13. MILLER: MILLER offers a diverse range of world-class plasma cutting machines and equipment. Suitable for customers who require powerful plasma cutters for cutting metals, MILLER maintains a strong industry reputation for reliability.

14. OERLIKON: Specializing in welding and plasma cutting equipment, OERLIKON focuses on innovation and quality. Their products cater to various industries, making OERLIKON a preferred choice for customers who demand versatile cutting solutions.

15. OTC: OTC is a Japanese brand known for its quality and reliability in the welding and cutting industry. Their plasma cutting machines offer excellent performance, making them appropriate for customers prioritizing excellent cutting results.

16. THERMAL DYNAMICS: A reputable brand in the plasma cutting industry, THERMAL DYNAMICS is known for its high-quality plasma cutting machines and systems. Their products are perfect for customers seeking the best plasma cutters built with reliability and durability.

17. TRAFIMET: TRAFIMET offers a range of quality welding and plasma cutting equipment. Featuring affordable pricing and reliable performance, TRAFIMET is ideal for customers seeking cost-effective plasma cutting solutions.

18. Panasonic: A leader in the industry, Panasonic offers a wide range of products, including plasma cutters and cnc machines. Their products provide excellent performance and innovation at competitive prices, making them ideal for customers seeking quality equipment from a reputable brand.

V. The Future of Plasma Cutting Equipment

1. Current trends in plasma cutting equipment:

The plasma cutting equipment industry is witnessing continuous innovation in its plasma torches, plasma cutting machines, and metal cutting technology. Some of the current trends include:

– Increased Automation: Integration of plasma cutting equipment with CNC (Computer Numerical Control) machines is becoming more widespread, allowing for precise cutting and higher productivity. This has led to growing interest in plasma cutter online sales and a rise in plasma cutter reviews to evaluate the best options.

– Continuous Pilot Arc Technology: This technology allows for uninterrupted cutting on expanded metal surfaces or metal sheets without the need to re-ignite the arc. This results in improved efficiency and reduced wear on consumable parts.

– Enhanced Portability: Development of portable plasma cutters that are more lightweight and compact has been increasingly popular, allowing for increased mobility and ease of use for various industries.

2. Anticipated innovations and improvements:

The future of plasma cutting equipment will witness further advancements in terms of quality, efficiency, and versatility. Some of the anticipated innovations include:

– Improved Cutting Accuracy: New systems will utilize more sophisticated plasma cutting torches and technology to enhance plasma cutting machine capabilities, resulting in better cut quality and reduced waste.

– Versatility: Future plasma cutters will be capable of handling a wider range of materials, including electrically conductive metals and metal surfaces, making the cheap plasma cutter market even more competitive.

– AI Integration: Artificial Intelligence (AI) may play a crucial role in enhancing productivity and precision in plasma cutting machine operations for better results and improving the customer experience.

– Eco-friendly Systems: The industry will focus on developing plasma torch technology that minimizes environmental impact while offering efficient and reliable metal cutting solutions.

3. Potential new entrants to the market:

As the demand for plasma cutting equipment increases and technology continues to advance, new entrants may emerge in the market. Potential newcomers could include:

– Existing welding and cutting equipment manufacturers who observe the success and demand for plasma cutting machines, leading them to expand their offerings.

– Electronics and engineering companies leveraging their expertise to develop advanced plasma torches and cutting systems for specialized applications.

– Startups and smaller companies focusing on niche segments of the market, such as specialized materials or customized cutting solutions, who can quickly adapt to changes and improvements in the field.

VI. Conclusion

The future of plasma cutting equipment lies in innovation and continuous developments in areas such as plasma torch technology, portability, cutting accuracy, and versatility. As online platforms facilitate the search and purchase of the perfect plasma cutter or plasma cutting machine, customer satisfaction and overall growth for the industry are likely to increase. These advancements in the field, along with new entrants to the market, will drive healthy competition and greater efficiency in metal cutting solutions.

Request A Free Quote

Have any questions about plasma alternative parts?

Don’t hesitate to contact us. Lasersourcing’s product specialists are very happy to help you and provide a variety of flexible and reliable solutions to help you solve various problems.

Tel

+86-15370952128

lasersourcing@hotmail.com

15370952128

+86-15370952128