Amada vs Bystronic: Choosing the Right Laser Cutting Machine for You

Laser cutting machines have become indispensable tools in the manufacturing industry, providing precise and efficient cutting solutions for a wide range of materials. Selecting the right laser cutting machine for your business is crucial to ensure optimal productivity and long-term success. Two major players in the market, Amada and Bystronic, offer various models with different features and capabilities. In this article, we will compare Amada and Bystronic laser cutting machines to help you make an informed decision for your business.

II. Amada Laser Cutting Machines

A. Brief History of Amada

Founded in 1946 in Japan, Amada has established itself as a global leader in the metalworking industry, with a focus on advanced sheet metal processing solutions. With over 70 years of experience in the manufacture of cutting machines, Amada continuously innovates to meet the ever-changing demands of its customers, constantly developing cutting-edge engineering solutions and setting industry standards for quality and performance.

B. Range of Amada Laser Cutting Machines

Amada offers a wide variety of laser cutting machines to suit different industries and applications, with models designed for both entry-level and high-production environments. Their range includes:

1. Fiber Laser Cutting Systems: These machines, such as the ENSIS Series, LCG Series, and VENTIS Series, utilize solid-state laser technology to provide faster cutting speeds and superior cut quality for a variety of applications.

2. CO2 Laser Cutting Systems: Amada’s CO2 laser cutting machines, including the FO M2 Series and the FOM2 RI Rotary Index Series, are ideal for processing various materials, including thicker plates and materials that are less suited for fiber laser cutting.

3. Automation Systems: Amada also offers automation solutions to complement their laser cutting machines. These include Material Storage Towers (MSTs), Flexible Manufacturing Systems (FMSs), and Load/Unload systems, which can be integrated with various Amada machines to increase productivity and efficiency.

C. Key Features and Benefits of Amada Machines

1. High Precision Cutting: Amada’s machines are known for their high accuracy and precision, thanks to their advanced motion systems, process monitoring technologies, and optimized cutting parameters. This ensures clean and accurate cuts for a variety of materials, from thin to thick sheets and complex geometries.

2. Fast Processing Times: Amada laser cutting machines offer rapid processing capabilities, reducing cycle times and increasing overall productivity. Their fiber laser machines, in particular, offer faster cutting speeds compared to CO2 lasers, ensuring that your business gets the most from its cutting processes.

3. Versatile Material Capabilities: Amada machines can process various materials, including mild steel, stainless steel, aluminum, brass, and more. This versatility allows businesses to cater to a range of applications and industries without the need for multiple machines.

4. Automation Options: Amada systems can be seamlessly integrated with loading and unloading systems to increase productivity and reduce labor costs. Automated systems like Material Storage Towers (MSTs) and Flexible Manufacturing Systems (FMSs) can help optimize material handling, minimize material changeover times, and improve overall workflow, allowing your business to maintain a competitive edge.

III. Bystronic Laser Cutting Machines

A. Brief History of Bystronic

Bystronic, a Swiss company founded in 1964, specializes in sheet metal processing solutions. With a focus on innovation, customer-centric design, and sustainability, Bystronic has become a reliable partner for businesses worldwide, gaining a solid reputation for high-quality, high-performance machines.

B. Range of Bystronic Laser Cutting Machines

Bystronic offers an extensive product line of laser cutting machines to address various customer needs and applications, ensuring a solution for most manufacturing demands. Their range includes:

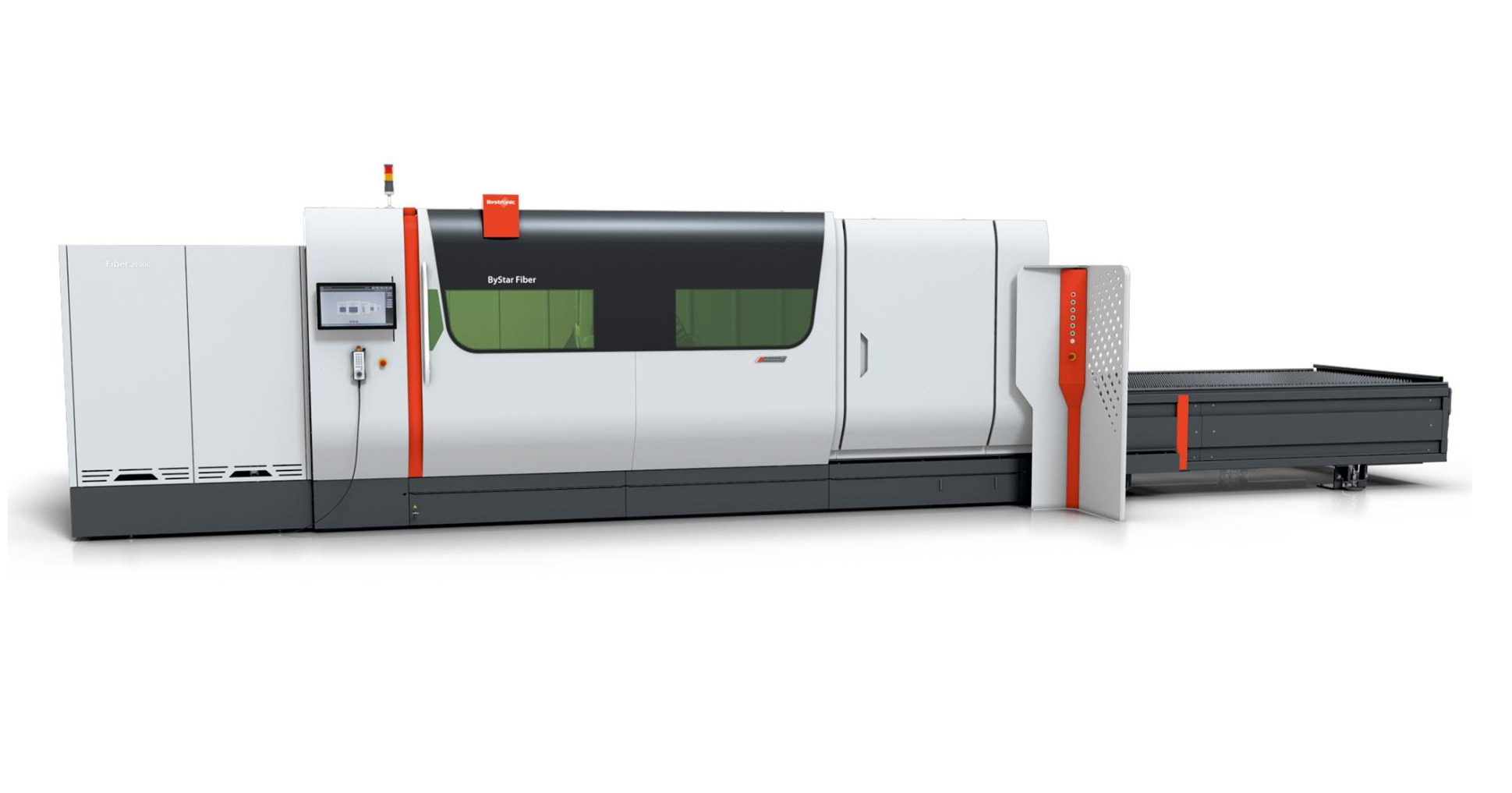

1. Fiber Laser Cutting Systems: Bystronic’s fiber laser cutting machines, such as the ByStar Fiber, BySprint Fiber, and BySmart Fiber series, offer high-speed cutting capabilities and superior energy efficiency for a wide range of materials.

2. CO2 Laser Cutting Systems: Bystronic’s CO2 laser cutting machines, like the BySpeed series, are known for their reliability and versatility, making them ideal for more demanding applications and materials.

3. Tube Laser Cutting Systems: Bystronic also provides specialized laser cutting machines for processing tubes and profiles, such as the ByTube series, enabling businesses to expand their service offerings.

C. Key Features and Benefits of Bystronic Machines

1. Industry-Leading Technology: Bystronic’s machines feature advanced technology, such as cutting-edge motion systems, intelligent sensor technology, and powerful fiber laser sources, allowing you to stay ahead in a competitive market and produce high-quality, precise components.

2. Energy-Efficient Solutions: Bystronic focuses on sustainable solutions, offering energy-efficient machines that reduce power consumption and environmental impact. Their fiber laser systems, in particular, boast significant energy savings compared to CO2 laser systems.

3. Wide Range of Material Capabilities: Bystronic machines can process a variety of materials, including steel, stainless steel, aluminum, copper, and more, giving businesses the flexibility to cater to diverse customer needs and industries.

4. Customized Software Options: Bystronic provides software solutions tailored to your specific manufacturing requirements, simplifying the cutting process and ensuring optimal results. Their BySoft 7 software, for example, features advanced nesting algorithms, 3D simulations, and integrated production monitoring tools, enabling efficient and accurate cutting operations.

IV. Comparing Amada and Bystronic Laser Cutting Machines

A. Side-by-Side Comparison

When comparing Amada and Bystronic laser cutting machines, both brands offer high-performance and reliable machines, catering to various industry needs. Here’s a more detailed comparison of some key aspects:

1. Precision Cutting: Amada is well-known for its high precision cutting capabilities with advanced motion systems and optimized cutting parameters, while Bystronic also offers high-quality results through its cutting-edge technology.

2. Processing Times: Amada laser cutting machines often have faster processing times, especially with their fiber laser cutting systems. Bystronic’s machines, while impressive, may require longer processing times in some instances.

3. Energy Efficiency: Bystronic is known for its focus on sustainable solutions and energy-efficient machines, while Amada also offers eco-friendly technologies, but they may not be as prominent as Bystronic’s offerings.

4. Automation Integration: Both companies provide automation options for their machines. Amada offers Material Storage Towers (MSTs), Flexible Manufacturing Systems (FMSs), and Load/Unload systems while Bystronic provides comprehensive system configurations, such as fully automated sorting solutions and integrated bending solutions.

5. System Costs: The total cost can vary significantly between models and configurations in each brand. In general, Amada machines tend to have a higher initial investment cost, while Bystronic machines might present lower acquisition costs but higher operational costs over time.

B. Pros and Cons of Each Brand

When considering Amada and Bystronic laser cutting machines, several factors will play a role in your decision-making, including costs, after-sales service, and future upgrade possibilities:

Amada:

Pros:

– High precision cutting and fast processing times

– Wide range of machines and automation options

– Decades of experience and established brand reputation

Cons:

– Higher initial investment costs compared to Bystronic machines

– Eco-friendly solutions may not be as advanced as Bystronic’s offerings

Bystronic:

Pros:

– Industry-leading technology and energy-efficient solutions

– Customized software and flexible material processing capabilities

– Possibly lower acquisition costs compared to Amada machines

Cons:

– Processing times may be longer in some applications

– Operational costs may be higher over time

It’s crucial to analyze not only the machine’s price but also maintenance, consumables, and energy consumption. Additionally, consider the quality of training, technical support, and after-sales service provided by each company to ensure a smooth operation and uninterrupted production.

Taking into account these factors will better equip you to make an informed decision as to which brand offers the most suitable laser cutting machines for your business needs and long-term goals.

V. Factors to Consider When Choosing a Laser Cutting Machine: Amada vs Bystronic

When deciding between Amada and Bystronic laser cutting machines for your business, it’s essential to consider several factors based on the unique characteristics of each brand. By taking their individual strengths and qualities into account, you can make an informed decision and select the perfect laser cutting machinery for your specific needs.

A. Specific Needs and Requirements

1. Material Processing: Both Amada and Bystronic can process various materials, including mild steel, stainless steel, aluminum, brass, and copper. Consider which brand provides the best cutting quality, speed, and energy efficiency for your business’s primary materials.

2. Production Volumes: Evaluate your average production volumes and peak periods, and consider the processing speed of Amada and Bystronic laser cutting machines. While Amada’s fiber laser cutters are known for their fast processing times, Bystronic’s advanced laser cutting technology can offer higher precision and sustainable solutions.

3. Automation Needs: Assess whether your business requires full, semi, or no automation integration. Both Amada and Bystronic offer automation options, but their specific features may vary. Consider the ease of integrating different automation levels and the potential benefits in terms of productivity and labor costs.

B. Budget and Cost Factors

1. Initial Investment: Determine your budget for a laser cutting machine and compare the initial costs of Amada and Bystronic machines. While Amada machines may feature higher upfront costs, Bystronic machines may boast cheaper prices at acquisition with potentially higher long-term operational expenses.

2. Maintenance Costs: Investigate the expected maintenance costs of Amada and Bystronic machines, including consumables, spare parts, cutting head replacements, and regular servicing. Consider their impact on your overall budget and choose the machine that best aligns with your business’s financial goals.

3. Operating Costs: Calculate the operational costs of both machine brands, factoring in energy consumption, software licensing, and any other recurring expenses. Bystronic’s CO2 laser cutting machines may provide better energy efficiency in the long run, while Amada machines, featuring fiber lasers and CO2 laser technology, could offer lower operational costs due to their fast processing times.

C. Technical Support and Ongoing Maintenance

1. Manufacturer Support: Research the level of technical support provided by both Amada and Bystronic. Consider factors such as the availability of service technicians, response times, and their reputations for providing excellent support.

2. Training: Determine whether Amada or Bystronic offers more comprehensive training for your staff, ensuring they can operate, maintain, and troubleshoot the laser beam cutting machines efficiently and effectively.

3. Warranty: Compare the warranty coverage and duration for both Amada and Bystronic machines, taking note of any unique conditions or exclusions that may impact your decision.

D. Future Expansion and Upgrades

1. Scalability: Opt for a machine that can grow with your business, either through component upgrades or expanded production capabilities. Both Amada and Bystronic offer varying levels of scalability, with fiber laser cutting machine adaptable to your company’s growth plans.

2. Compatibility: Ensure the machine you choose can integrate with additional equipment or software you may require in the future. Consider the compatibility of both Amada and Bystronic machines with material handling systems, production management software, and other cutting parameter technologies you might need.

3. Technology Lifespan: Choose a machine that incorporates the latest laser cutting technology, such as fiber laser technology, to future-proof your investment. Both Amada and Bystronic are dedicated to innovation, so research which brand consistently stays ahead of the curve in terms of technological advancements in fiber laser cutter.

By carefully examining these factors while keeping the specific characteristics of Amada and Bystronic in mind, you can make an informed decision and select the most suitable laser cutting machine for your business’s unique requirements, paving the way for long-term success. In the end, factors such as aluminum cutting, laser beam precision, and fiber laser machine efficiency will play a crucial role in your decision.

VI. Conclusion

In summary, both Amada and Bystronic offer high-quality laser cutting machines, and the best choice for your business will depend on your unique requirements and priorities. We encourage you to research and test both brands to determine which one aligns best with your needs. Keep in mind the factors mentioned in this article to make the best decision for your business and ensure long-term success.